Edge rolling method of edge rolling machine

A technology of rolling machine and frame, which is applied in the field of rolling of rolling machine, can solve the problems of inconvenient adjustment of roller shaft, simple structure, screw misalignment, etc., to ensure work efficiency and forming effect, reasonable rolling method, good molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

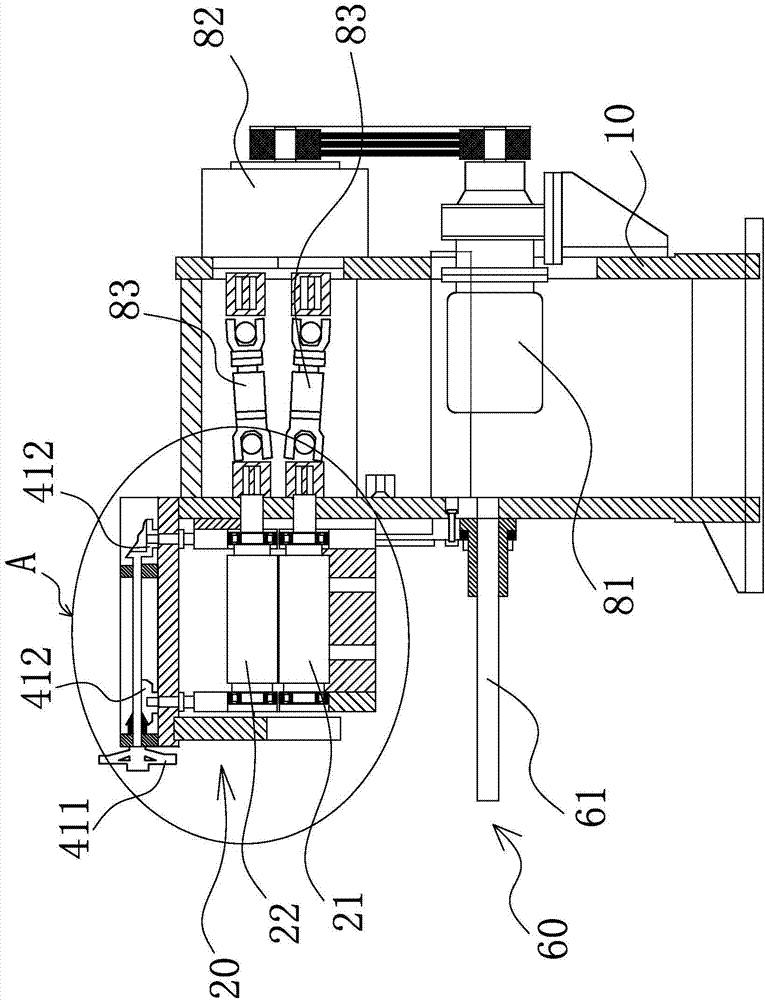

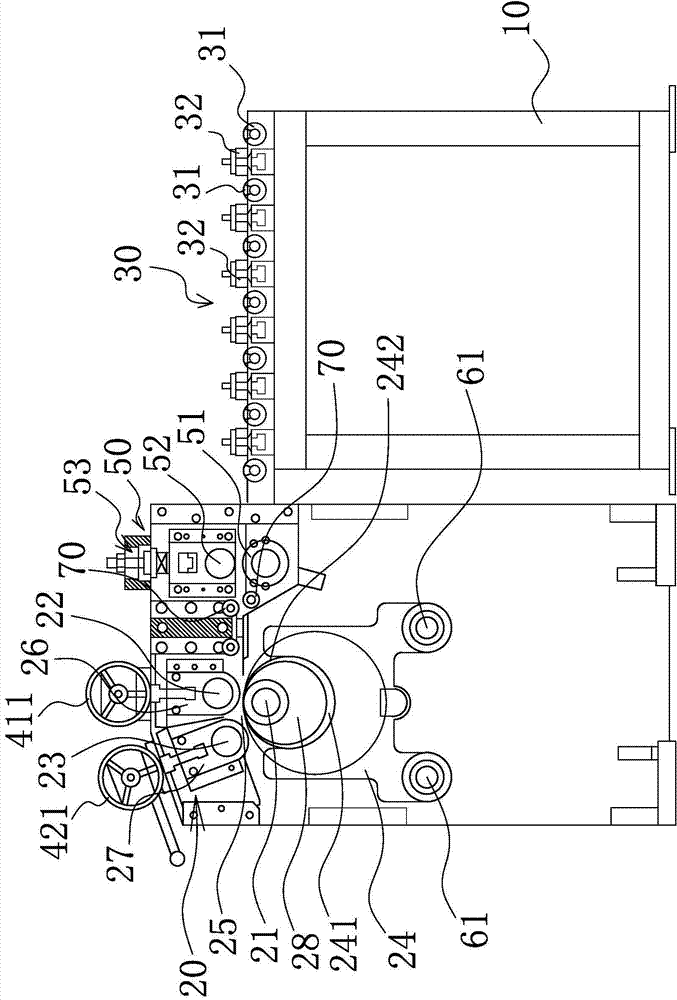

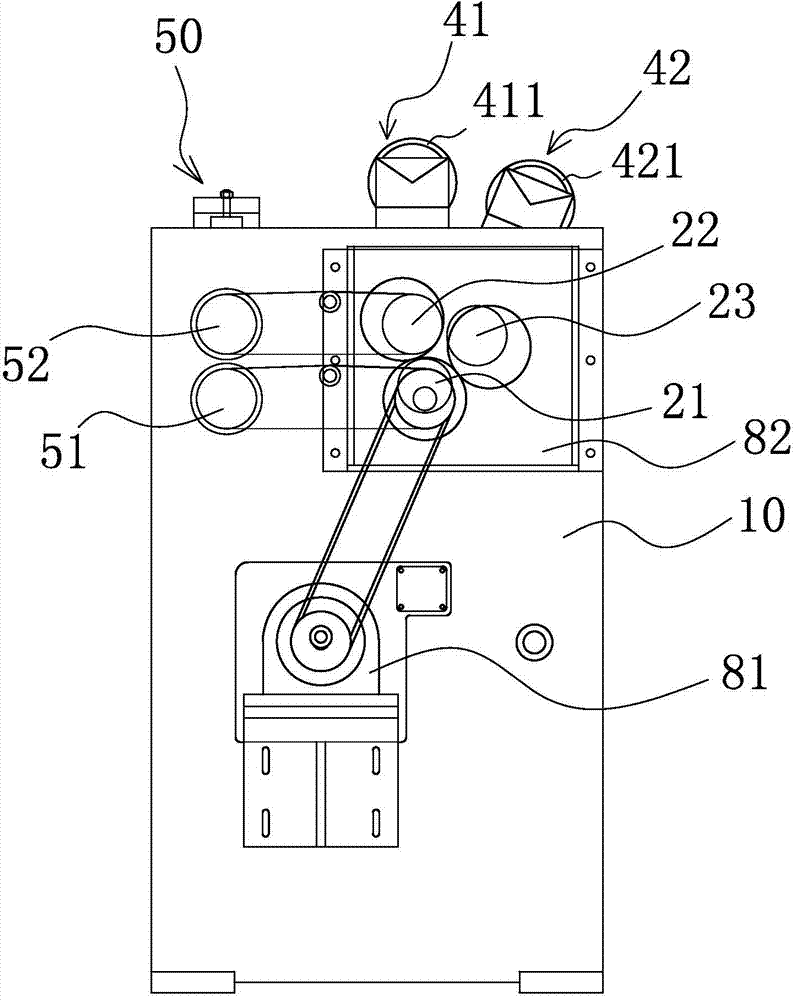

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0032] The invention protects a rounding method of a rounding machine, which is suitable for the rounding machine to bend and shape strips (plates) into required automobile wheel rims.

[0033] like Figure 1 to Figure 4 As shown, the rolling method of this rolling machine includes the following steps:

[0034] Step 1: Place the strip material on the incoming material mechanism 30 and transport the strip material to the propulsion mechanism 50 by the incoming material mechanism 30;

[0035] Step 2: The strip that reaches the propulsion mechanism 50 is further pushed by the propulsion mechanism 50 into the transition passage 25. When the strip passes through the transition passage 25, the main roller 21, the first adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com