Poppy primary processing integrated device and processing method

An integrated device and technology of poppy fruit, applied in chemical instruments and methods, solid separation, separating solids from solids with airflow, etc., can solve problems such as high labor intensity for operators, inability to guarantee processing quality, damage to poppy seeds, etc. , to achieve the effects of improving production efficiency and processing quality, saving poppy fruit raw materials, and reducing power transmission auxiliary equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

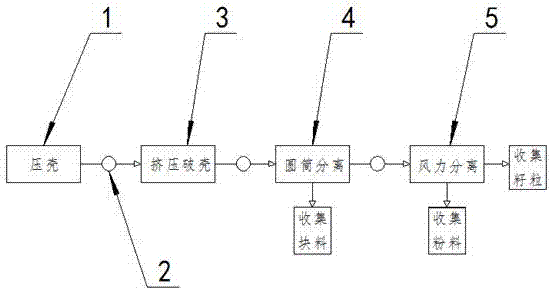

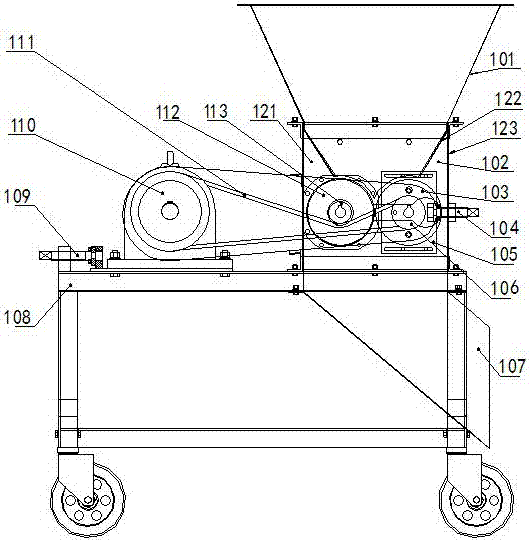

[0037] Such as figure 1 , Figure 3 to Figure 6 An integrated device for primary processing of poppy fruit shown, which includes a poppy fruit shell breaker 1, an extrusion shell breaker 3, a cylinder separation device 4, a wind separation device 5, and a discharge port 107 of the poppy fruit shell breaker 1 It is connected with the feeding port of the extruding shell breaking machine 3 through the conveying device 2, and the discharge port of the extruding shell breaking machine 3 is connected with the feeding port of the cylinder separating device 4 through the conveying device 2, and the cylinder separating device 4 The discharge port of the poppy fruit shell is connected with the feed port of the wind separation device 5 by the conveying device 2; The feeding hopper 101, the bottom of the broken shell box 102 is provided with a discharge port 107, and the inner cavity of the broken shell box 102 is provided with a driving roller 103 and a driven roller 112 arranged in par...

Embodiment 2

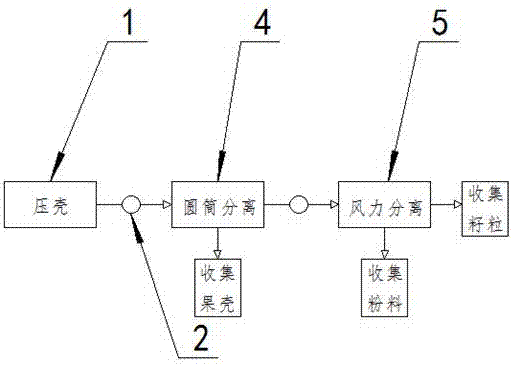

[0046] Such as figure 2 , image 3 The integrated device for primary processing of poppy fruit shown in the figure bypasses the extruding husk breaking machine in Example 1. This integrated device can crush the poppy husk so that the seeds, husk and powder are separated and collected.

[0047] A method for primary processing of poppy fruit. This method utilizes the aforementioned integrated device for primary processing of poppy fruit to crush the poppy husk so that the seeds, husk and powder are separated and collected. The processing process is as follows: the operator feeds the poppy fruit into The poppy fruit shell crushing machine 1 crushes the fruit shell to make a mixture containing seeds, shells and powder, and then feeds the mixture into the cylinder separation device 4 through the conveying device 2, sorts and collects the lumps Then the powder sieved by the cylinder separation device 4 is fed into the wind separation device 5 through the conveying device 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com