Multi-head precise three-dimensional numerical control planer-type milling machine

A gantry milling machine, precision technology, applied in the field of milling processing machinery, can solve the problems of increased moving resistance of the horizontal carriage, increased frictional resistance of the horizontal guide rail, and affecting the service life of the horizontal guide rail, so as to improve drive sensitivity, reduce power consumption, increase Effects of Stability and Machining Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

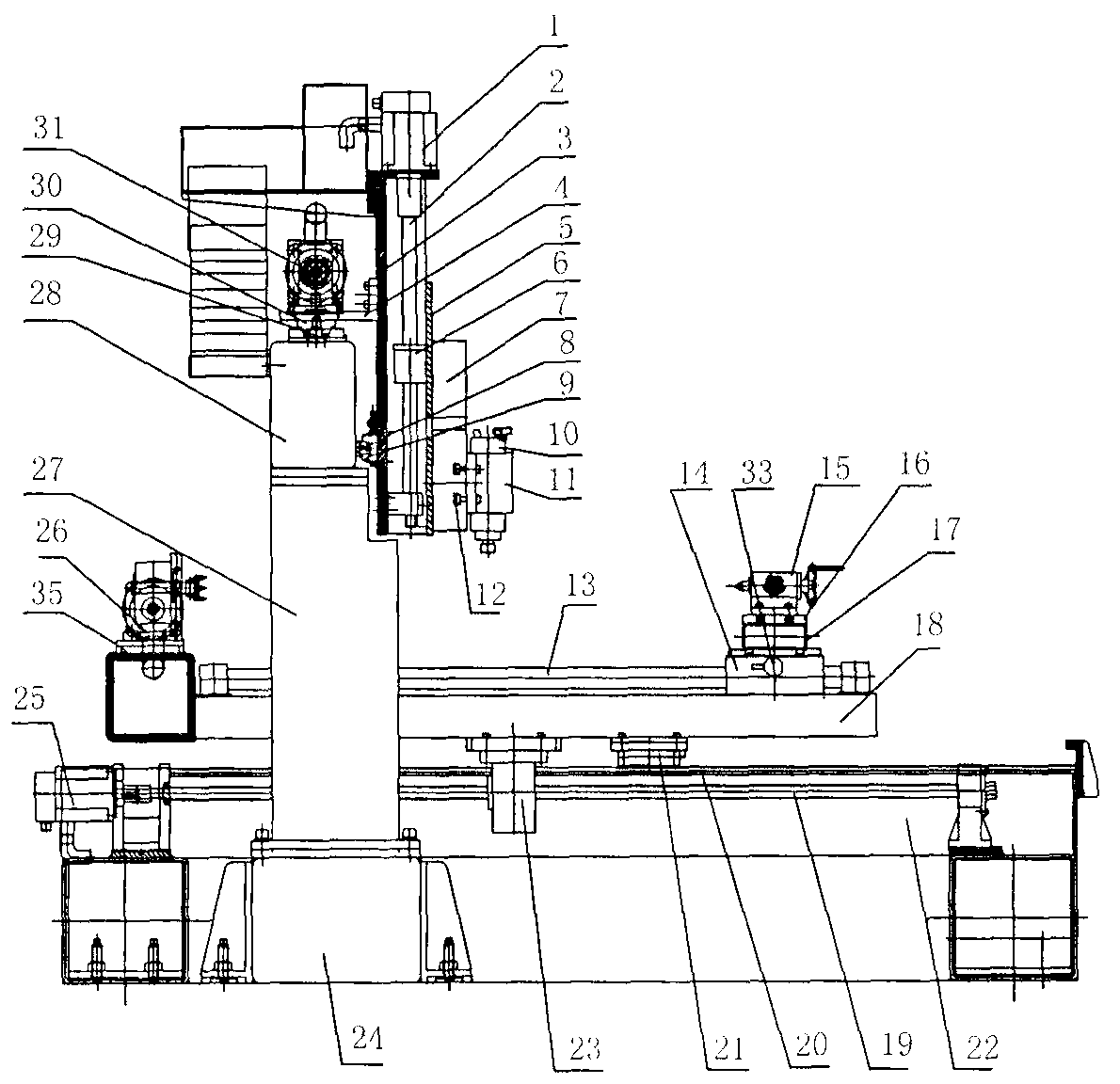

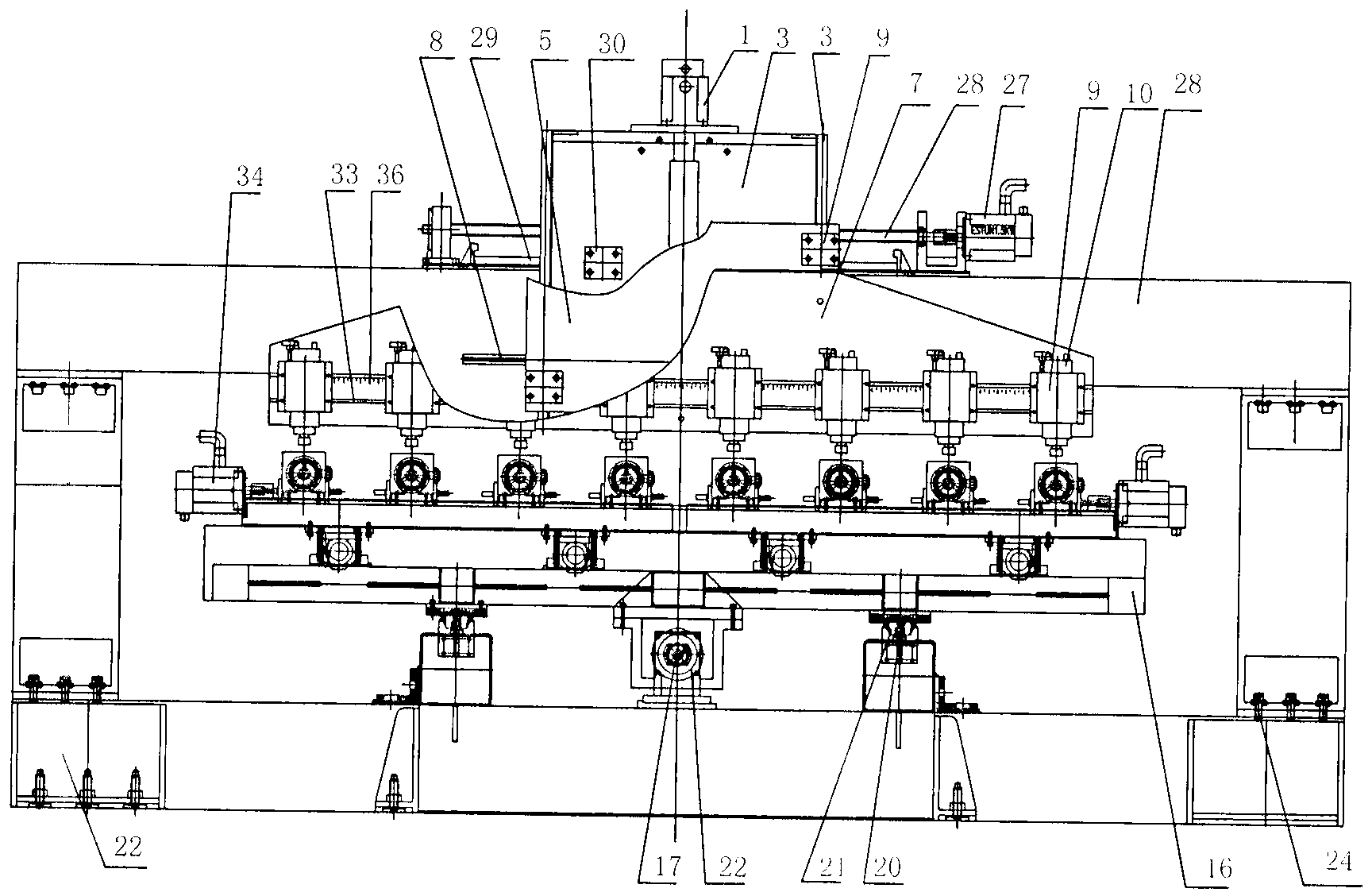

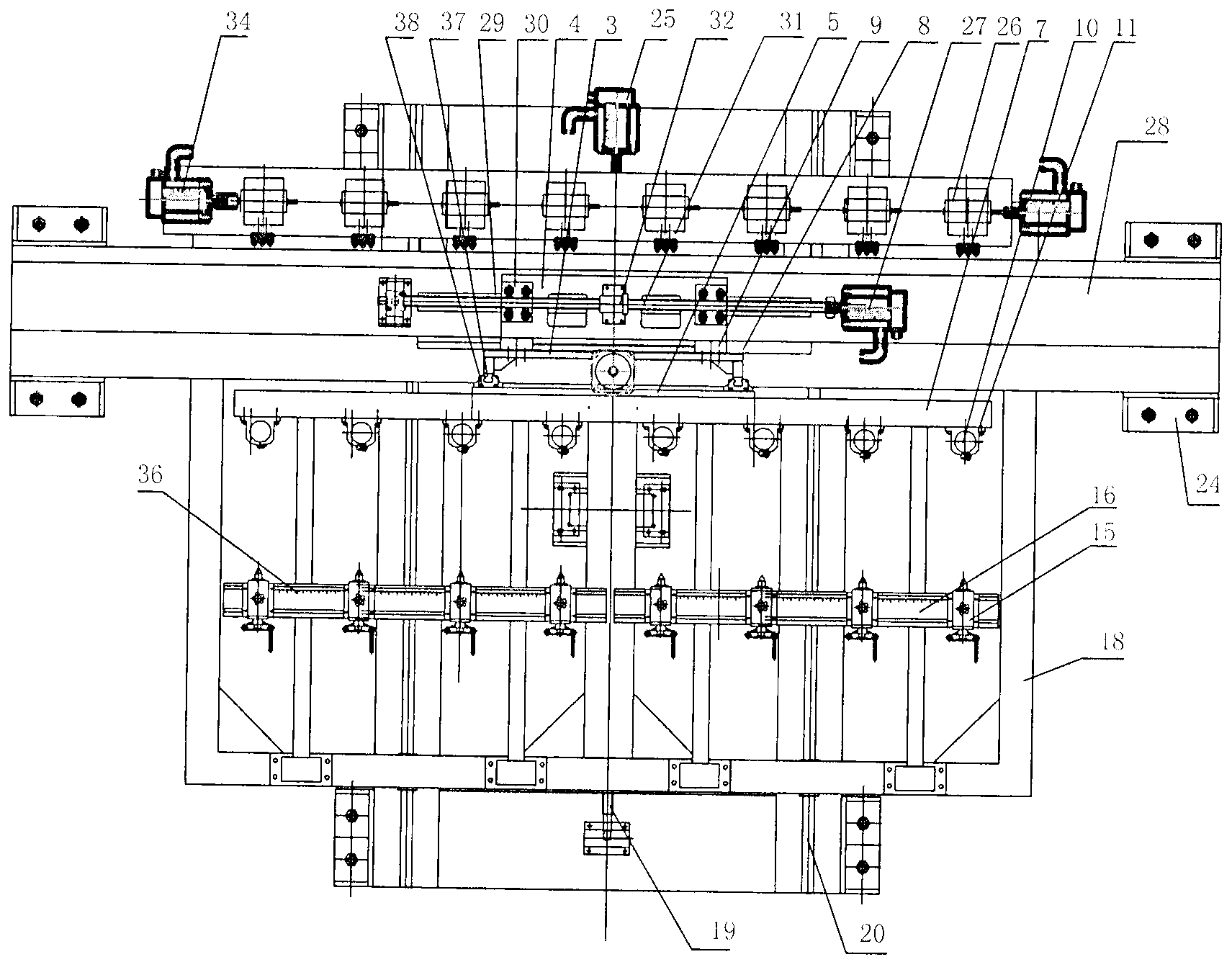

[0024] Numerical control milling machine of the present invention is described in further detail in conjunction with accompanying drawing:

[0025] The multi-head precision gantry engraving equipment of the present invention has a structure comprising: a horizontal Chinese-shaped machine base, a gantry frame 28, a longitudinally movable working platform 18, a workpiece positioning drive assembly, and a two-way precision drive composite machine head, wherein the horizontal Chinese-shaped machine base is It is made by vertically connecting the straight frame 22 and the square frame 24. The square frame 24 is set above the straight frame 22 through bolts, and the two ends of the straight frame 22 are connected with the gantry frame by the bolts 24. 28 lower ends are connected, and the top of the mouth-shaped support 24 is provided with a longitudinal slideway 20, and the middle of the longitudinal slideway 20 is provided with a longitudinal drive screw 19, and the end of the longi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com