Liquid dripping type photo-curing following printing system and liquid dripping type photo-curing following printing method

A printing system and light-curing technology, applied in the field of 3D printing and tissue engineering, can solve the problems of material pollution, long printing cycle, waste, etc., and achieve the effect of realizing processing requirements and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

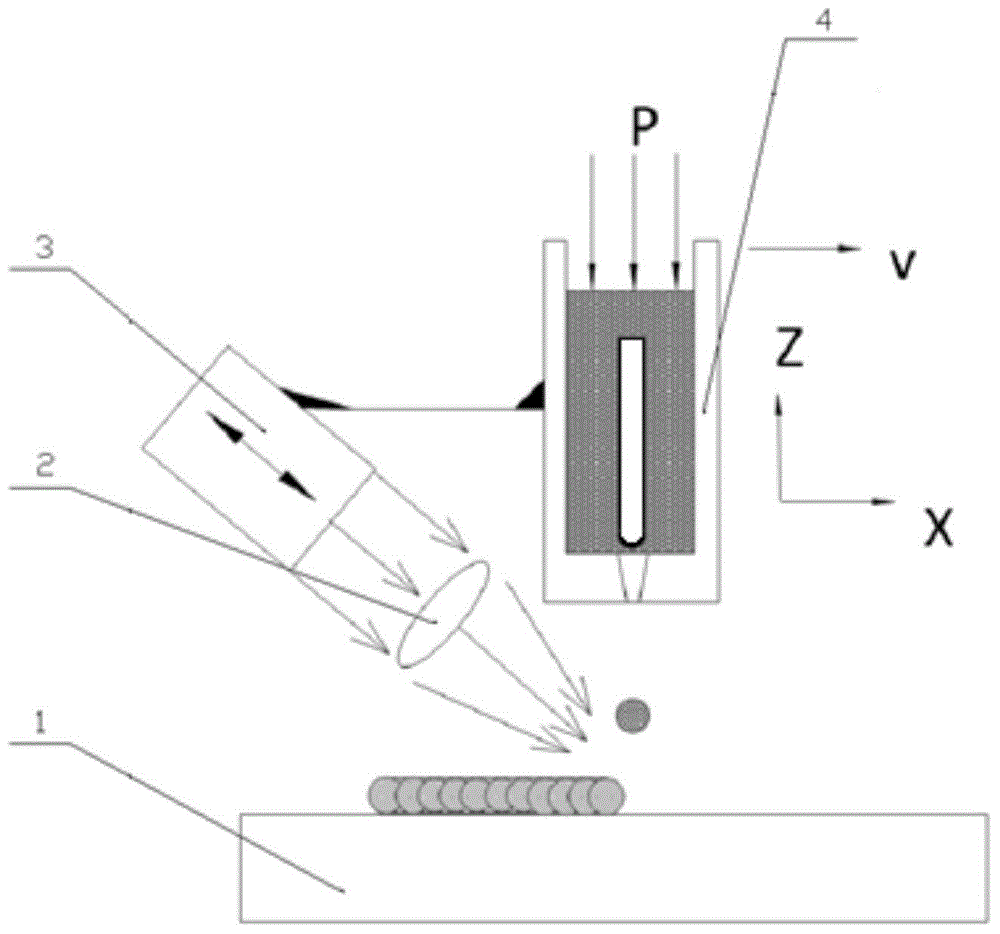

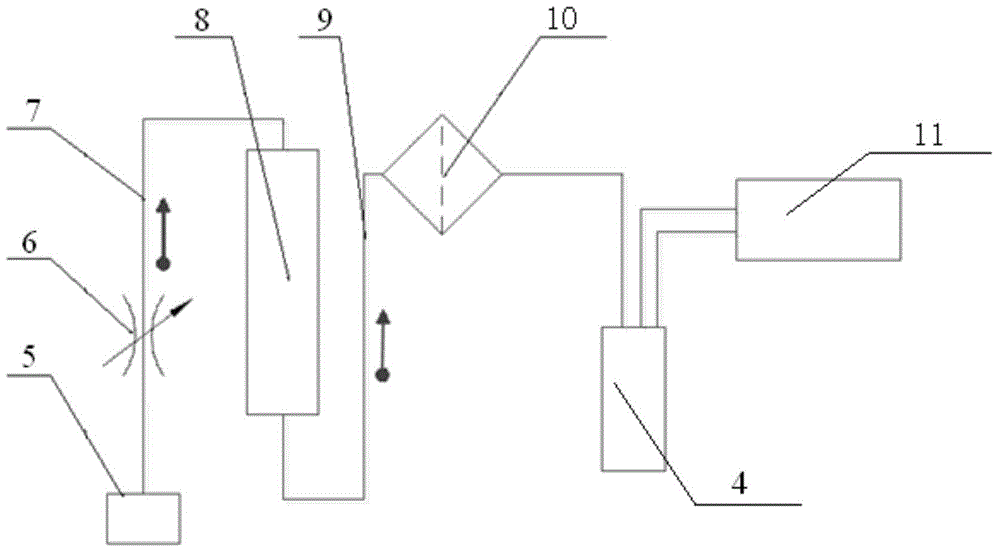

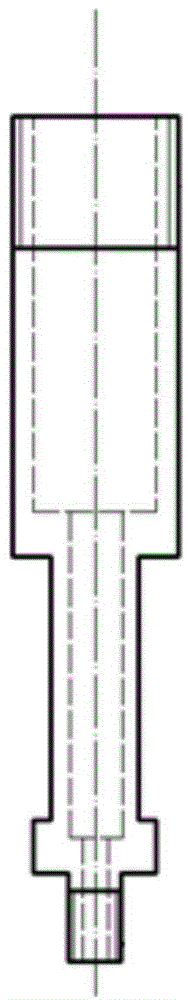

[0026] refer to figure 1 , the dripping type photocuring follow-up printing system of the present invention includes a two-dimensional mobile platform, a substrate 1, a light source 3, a focusing lens 2, a photocuring liquid supply system, a solenoid valve nozzle 4, and is used to control the solenoid valve nozzle 4 controller 11, and a one-dimensional mobile platform for driving the substrate 1 to move vertically; the substrate 1 is fixed on the one-dimensional mobile platform, and the light source 3, focusing lens 2 and solenoid valve nozzle 4 are fixed on the two-dimensional On the mobile platform, the light emitted by the light source 3 is focused by the focusing lens 2 to form a light spot on the substrate 1, and the light spot is located directly below the liquid outlet of the solenoid valve nozzle 4, and the liquid inlet of the solenoid valve nozzle 4 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com