Method for improving soft magnetic properties of bulk amorphous alloy Fe-M-B

An amorphous alloy, fe-m-b technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of soft magnetic amorphous annealing, etc., to reduce alloy coercivity, inhibit precipitation, and improve comprehensive magnetic properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

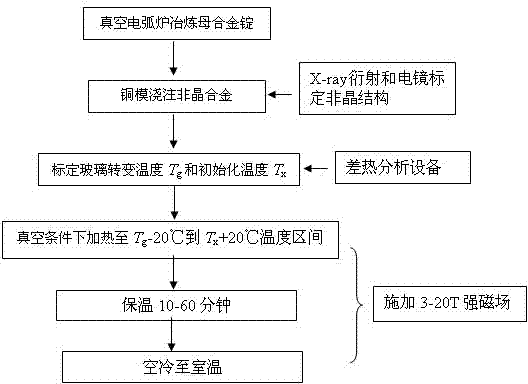

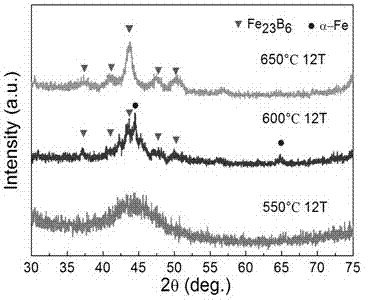

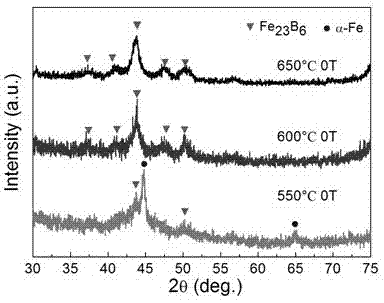

[0025] Formulated Fe in proportion 71 (Nb 0.8 Zr 0.2 ) 6 B 23 Alloy raw materials, that is, by atomic percentage, Fe content 71at%, B content 23at%, Nb4.8at%, Zr1.2at%, using vacuum arc melting at 10 -3 Preparation of Fe at Pa 71 (Nb 0.8 Zr 0.2 ) 6 B 23 master alloy, and then adopt copper mold suction casting to prepare bulk amorphous alloy Fe 71 (Nb 0.8 Zr 0.2 ) 6 B 23 , to obtain Fe with a diameter of 1 mm 71 (Nb 0.8 Zr 0.2 ) 6 B23 Round rod, take its cross section for X-ray diffraction, its diffraction pattern is a typical amorphous diffuse scattering peak, indicating that the round rod is a completely amorphous structure, the Fe 71 (Nb 0.8 Zr 0.2 ) 6 B 23 Differential thermal analysis of bulk amorphous alloys can calibrate their glass transition temperature T g 555°C, the initial temperature of crystallization T x It is 598°C.

[0026] Take the Fe 71 (Nb 0.8 Zr 0.2 ) 6 B 23 The bulk amorphous alloy is placed in a strong magnetic field vacuum...

Embodiment 2

[0030] Prepare bulk amorphous alloy Fe by batching, vacuum arc melting and copper mold suction casting according to Example 1 71 (Nb 0.8 Zr 0.2 ) 6 B 23 , put the alloy in a vacuum heat treatment furnace with a strong magnetic field, and keep it warm at 550°C for 10 minutes. During the heat preservation process, a strong magnetic field of 3T is applied, and the coercive force of the alloy drops to 20A / m rapidly, while the saturation magnetic induction increases from the original state of the alloy to 113 ±1emu / g increased to 128.7±1emu / g.

Embodiment 3

[0032] Prepare bulk amorphous alloy Fe by batching, vacuum arc melting and copper mold suction casting according to Example 1 71 (Nb 0.8 Zr 0.2 ) 6 B 23 , the alloy is placed in a high magnetic field vacuum heat treatment furnace, and kept at 600°C for 10 minutes. During the heat preservation process, a 20T strong magnetic field is applied, and the coercive force of the alloy drops to H c =9.8A / m, the saturation magnetic induction is significantly higher than that of the initial alloy, which is 145.7±1emu / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com