Automotive luggage rack bar processing center

A technology for automotive luggage racks and machining centers, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as increased production costs, low processing efficiency, and complicated operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

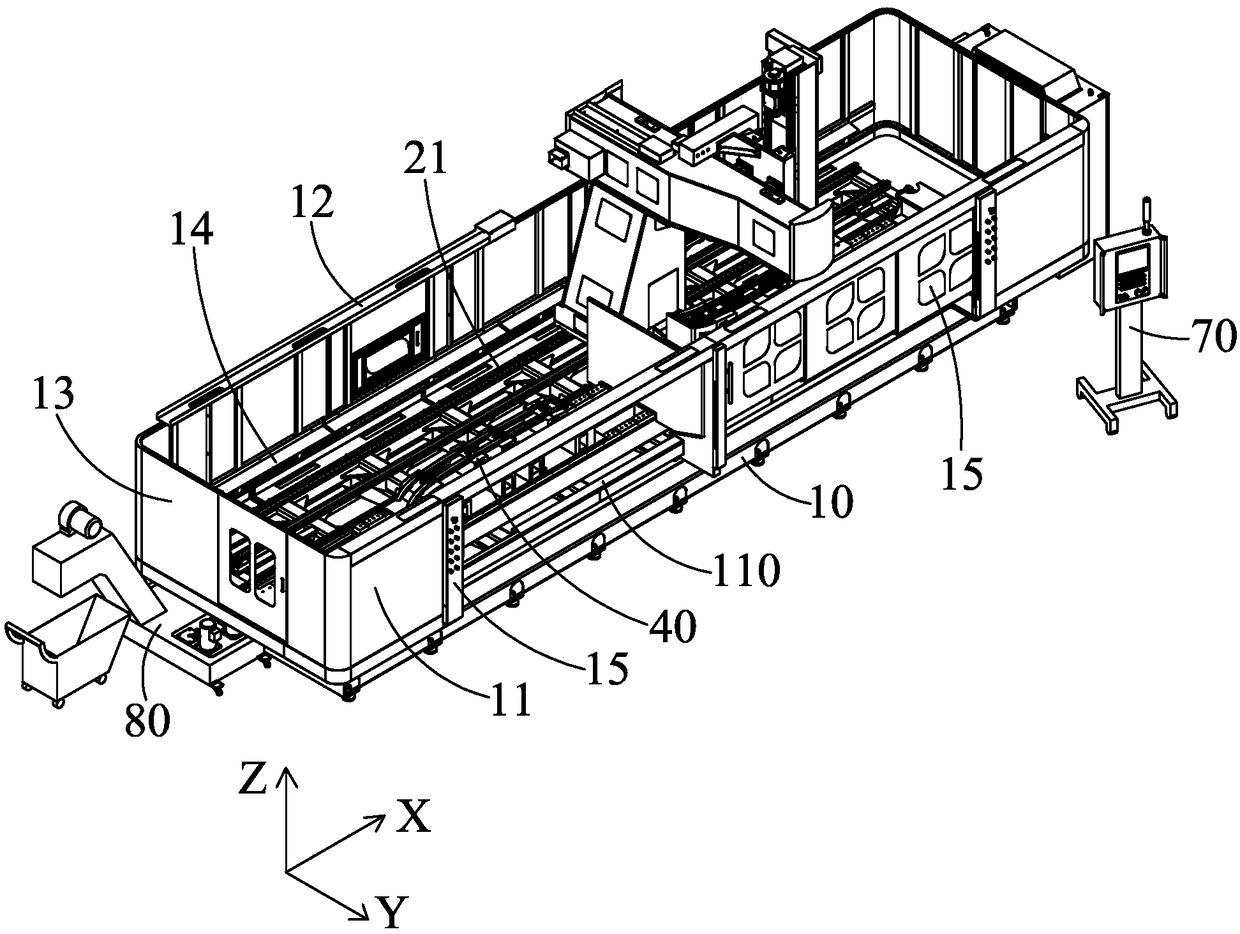

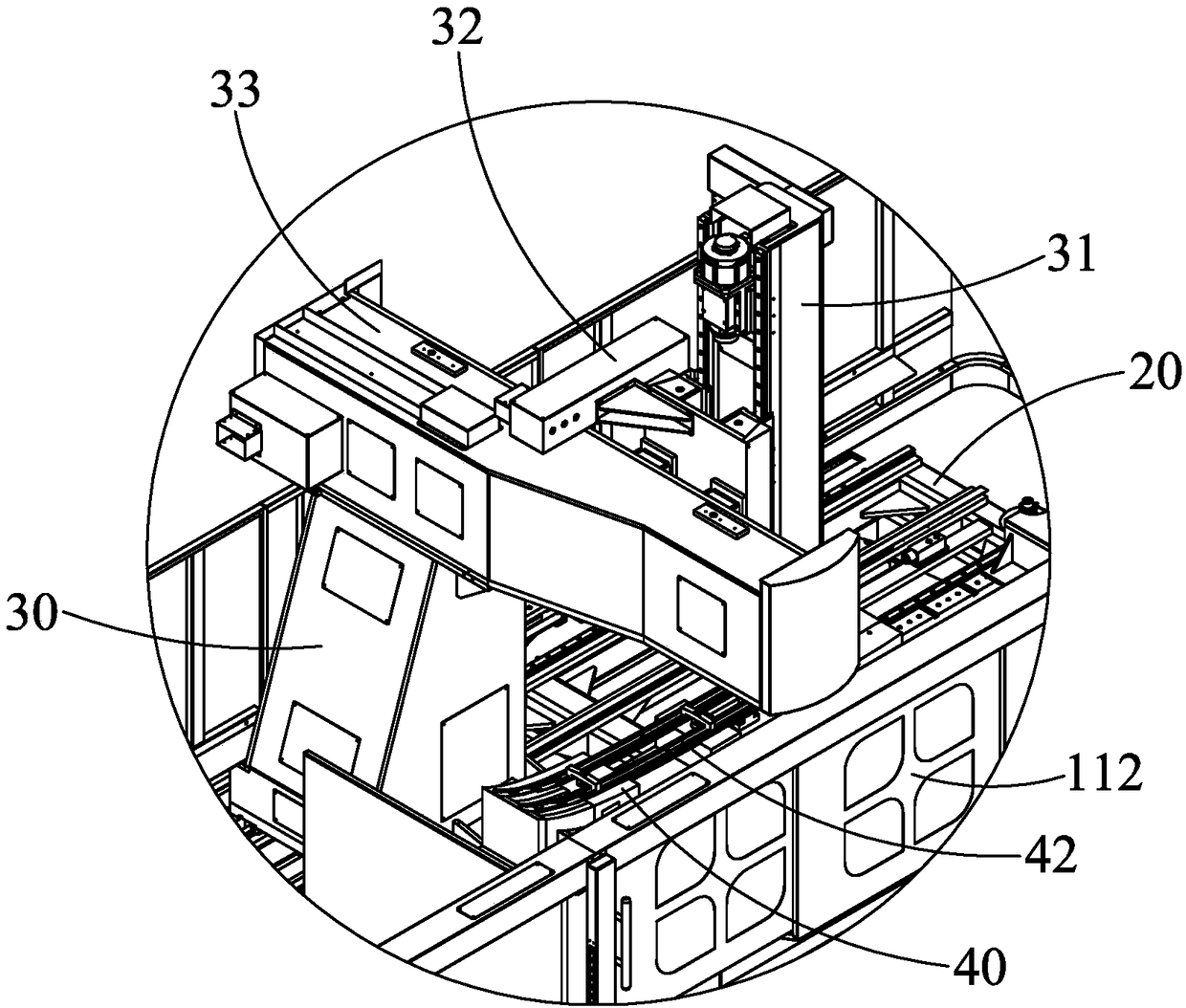

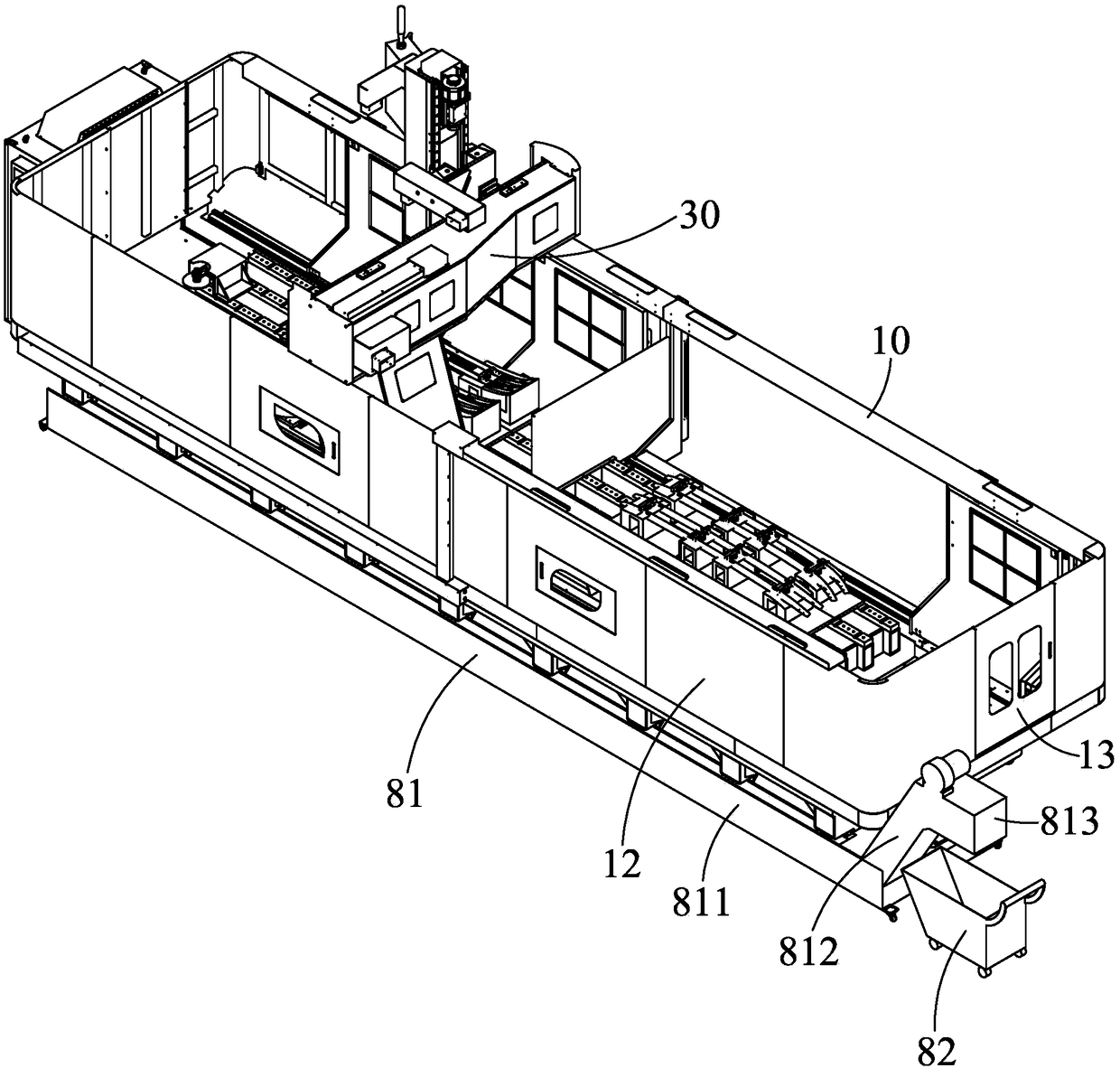

[0016] see Figure 1 to Figure 8 As shown, the automotive luggage rack rod machining center of the present invention includes a housing 10, a machine platform 20, a processing mechanism 30, two tooling 40, a first tool magazine 50, a second tool magazine 60, an operating table 70 positioned at the outside of the housing 10 and Automatic chip removal mechanism 80.

[0017] The housing 10 includes a front end wall 11, a rear end wall 12, two side walls 13 and a room 14 formed between the front end wall 11, the rear end wall 12 and the two side walls 13, a machine table 20, a processing mechanism 30, a tooling 40 and A tool magazine 50 is located within room 14 . The front end wall 11 is provided with two inlets and outlets 110 separated left and right, each inlet and outlet 110 is equipped with an automatic sliding door 15 capable of moving left and right. The automatic sliding door 15 includes an upper door 151, a middle door 152 extending inwardly and obliquely downward from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com