Punching machine

A punching machine and punching technology, applied in the direction of punching tools, metal processing equipment, manufacturing tools, etc., can solve the problems of bumper bumper punching processing and the position of the punching mechanism can not be adjusted, etc., to improve product quality , Improve flexibility, expand the effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

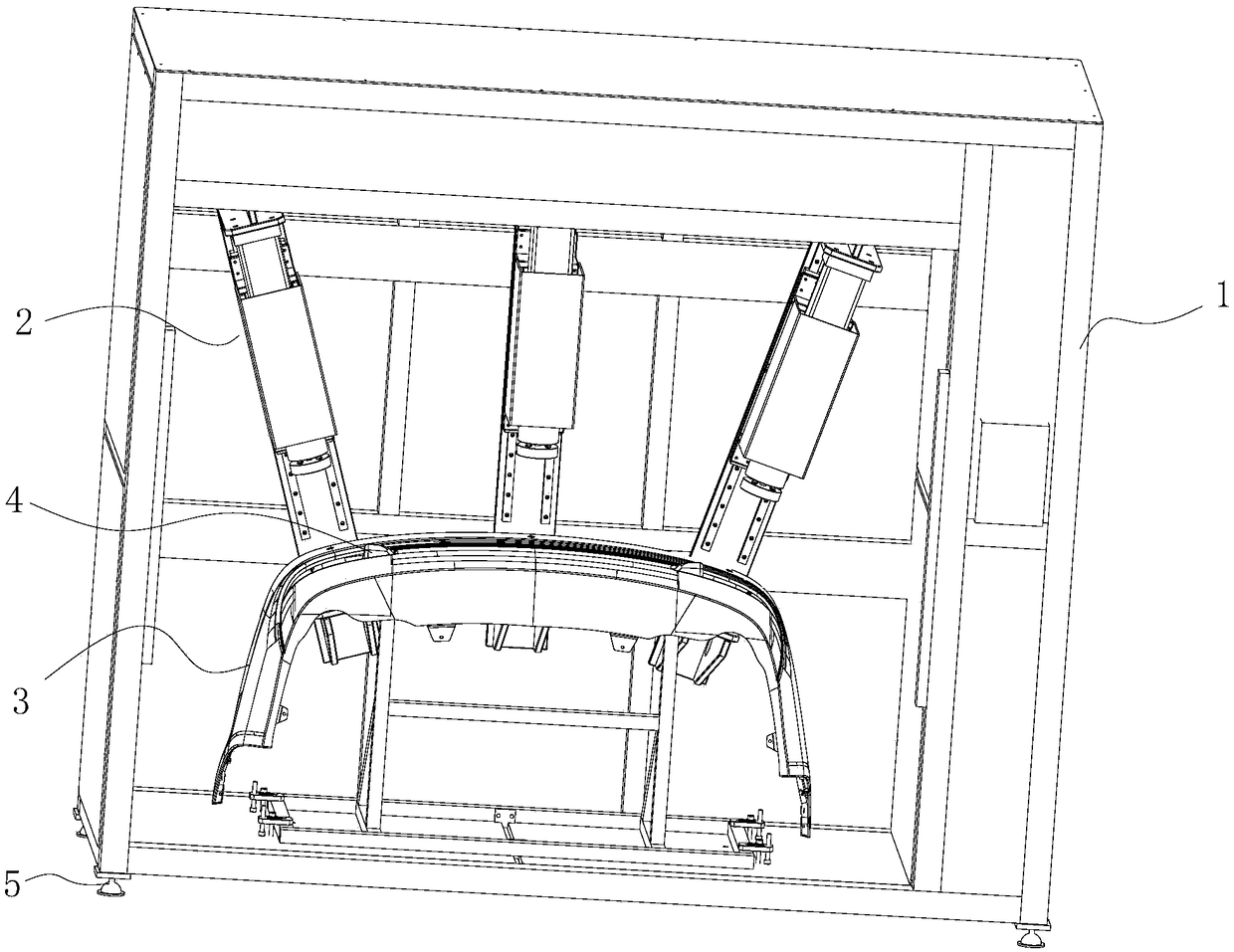

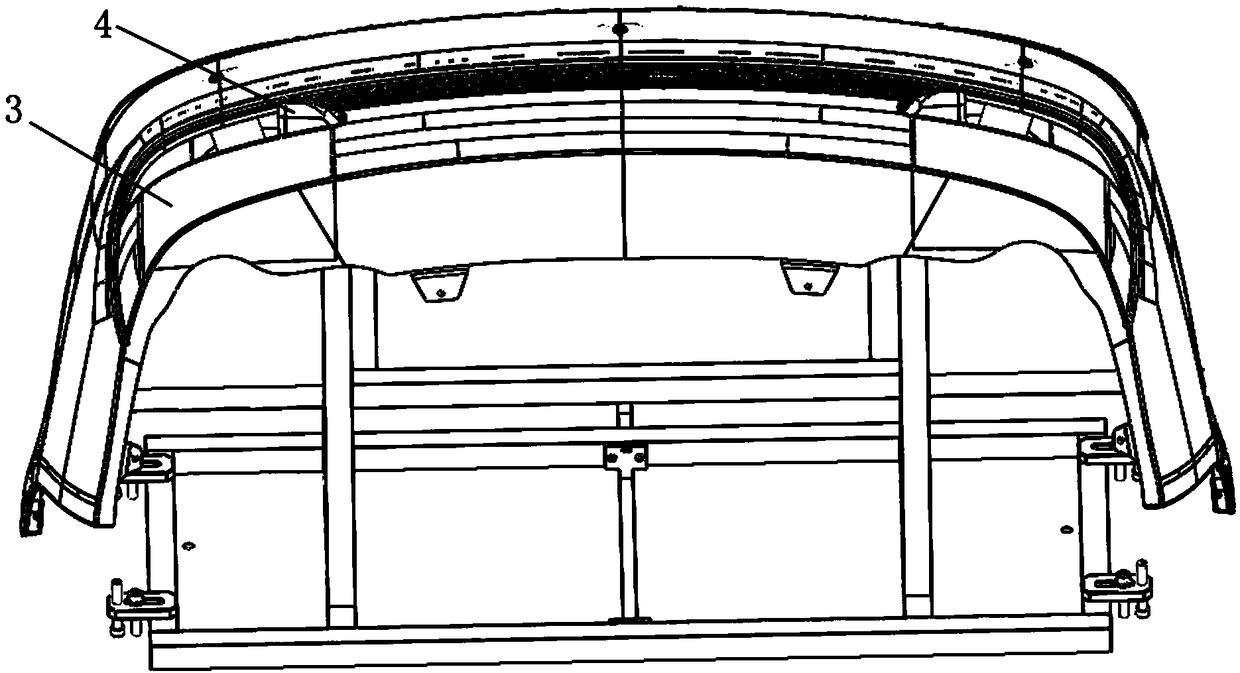

[0043] Such as Figure 1 to Figure 4 As shown, a punching machine is used for punching a workpiece 3 with a bent surface.

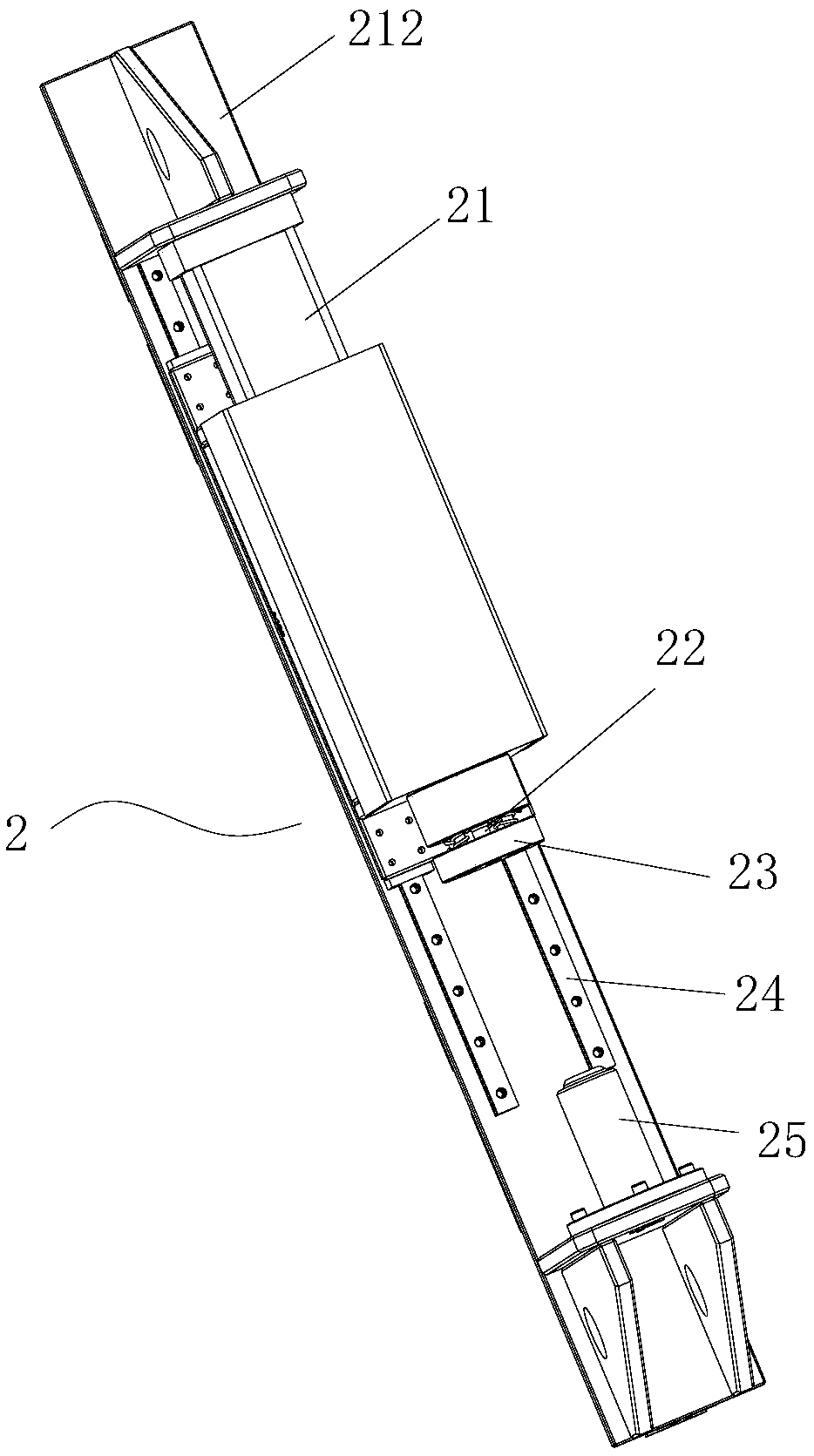

[0044] The punching machine includes a punching device, and the punching device includes a plurality of punching mechanisms 2 positioned above the workpiece. The plurality of punching mechanisms 2 are arranged at an angle along the contour of the workpiece 3, each The punching mechanism 2 includes a punch 22 .

[0045] The punching mechanism 2 further includes a mounting frame 212 and a first driving part 21 for driving the punch 22 to move, and the first driving part 21 is arranged on the mounting frame 212 . In this embodiment, the first driving part 21 is a hydraulic cylinder or an air cylinder. One end of the piston rod of the hydraulic cylinder or air cylinder is connected with the punch 22 through a connecting piece.

[0046] In order to meet the punching processing requirements of different apertures, in this application, the punch 22 is detachabl...

Embodiment 2

[0062] The structure and principle of this embodiment and embodiment 1 are basically the same, the difference is:

[0063] Different from the workpieces with different punching positions in Embodiment 1, it is necessary to change the installation position of the punching mechanism on the frame 1 to realize the relative positional relationship between the punch 22 and the punching position of the workpiece change. In this embodiment, the installation position of the punching mechanism 2 remains unchanged, but its installation angle can be changed. By changing its installation angle on the frame 1, the distance between its punch 22 and the punching position can be realized. Adjustment.

[0064] In this embodiment, each punching mechanism 2 is installed on the frame through at least one installation component. The installation assembly includes a fastener and a rotating part. The punching mechanism 2 can rotate around the rotating part. When the punching mechanism rotates until...

Embodiment 3

[0066] The structure and principle of this embodiment and embodiment 1 are basically the same, the difference is:

[0067] Different from the workpieces with different punching positions in Embodiment 1, several installation stations need to be set according to the positions to be punched of commonly processed workpieces, so as to change the installation position of the punching mechanism. In this embodiment, the adjustment of the installation position of the punching mechanism is realized through the following installation slots.

[0068] Such as Figure 5 to Figure 7 As shown, in this embodiment, the frame 1 is provided with a mounting groove for mounting the punching mechanism 2, and the extending direction of the mounting groove is at least consistent with the outline of a part of the workpiece 3, That is to say, the installation groove can be a straight guide chute, or a guide chute with a curved portion as the outline of the workpiece 3 . In this embodiment, the punchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com