B-axis cutter holder device of a turn-milling complex machining center

A composite machining center and composite processing technology, which is applied in positioning devices, metal processing, metal processing equipment, etc., can solve the problems of difficult to meet the processing accuracy requirements of parts, damaged spindle bearing accuracy, and high rigidity requirements of the mechanism, so as to improve rigidity, cutting tools, etc. The effect of short overhangs and refined angular positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

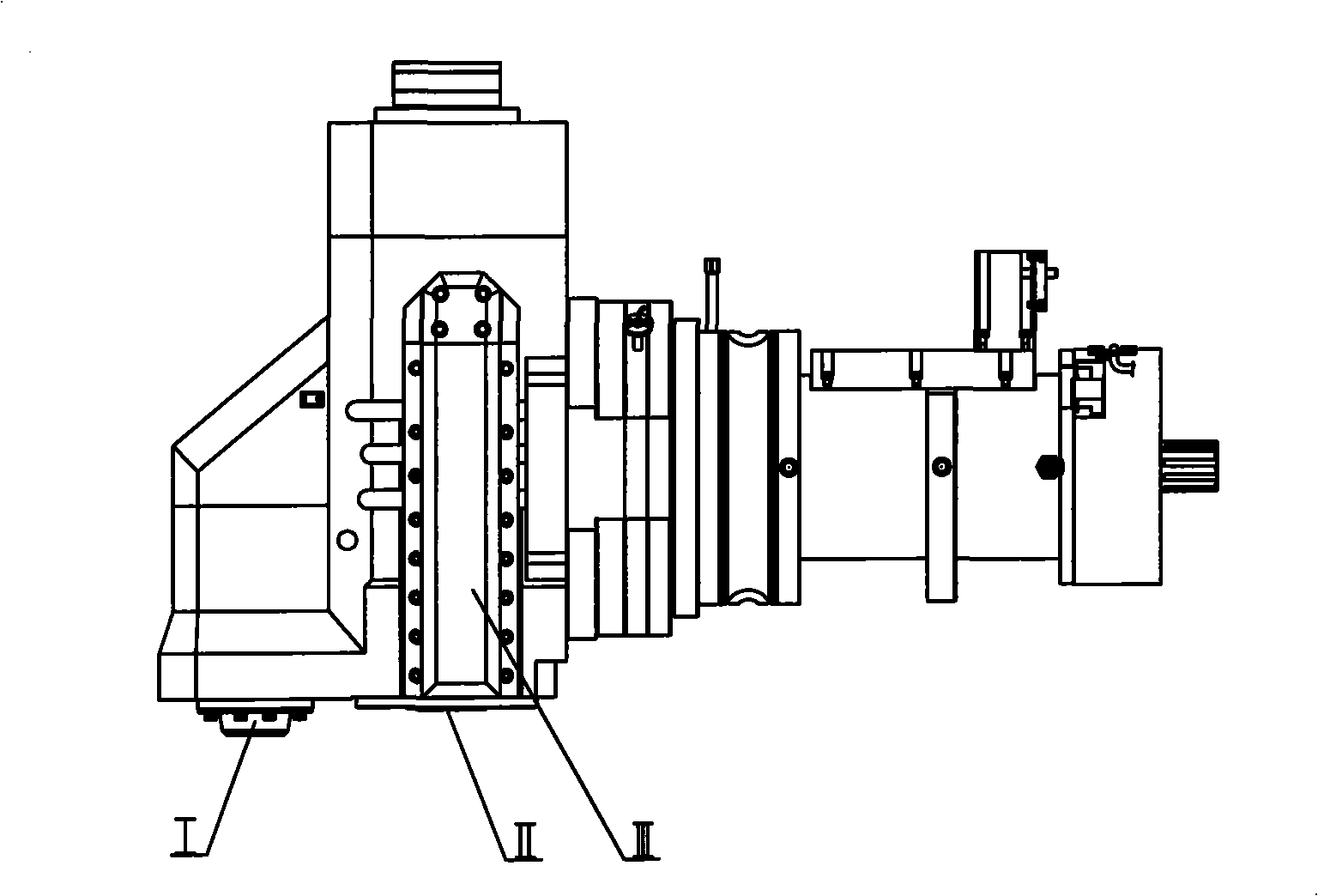

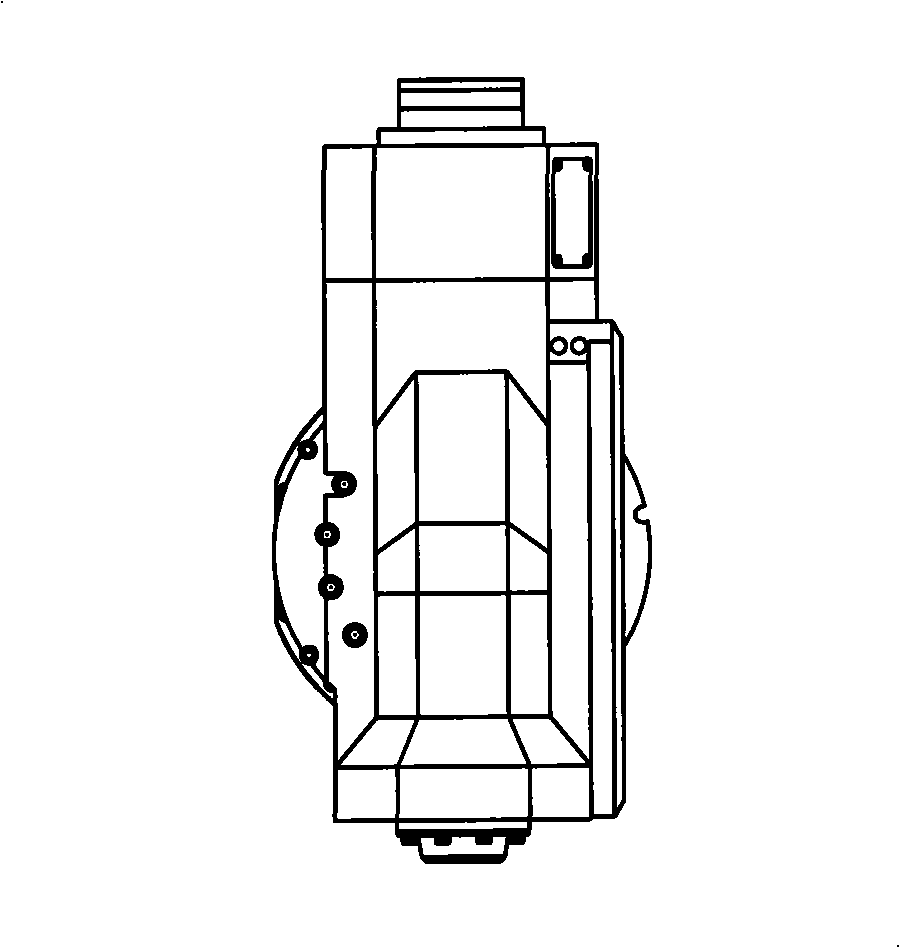

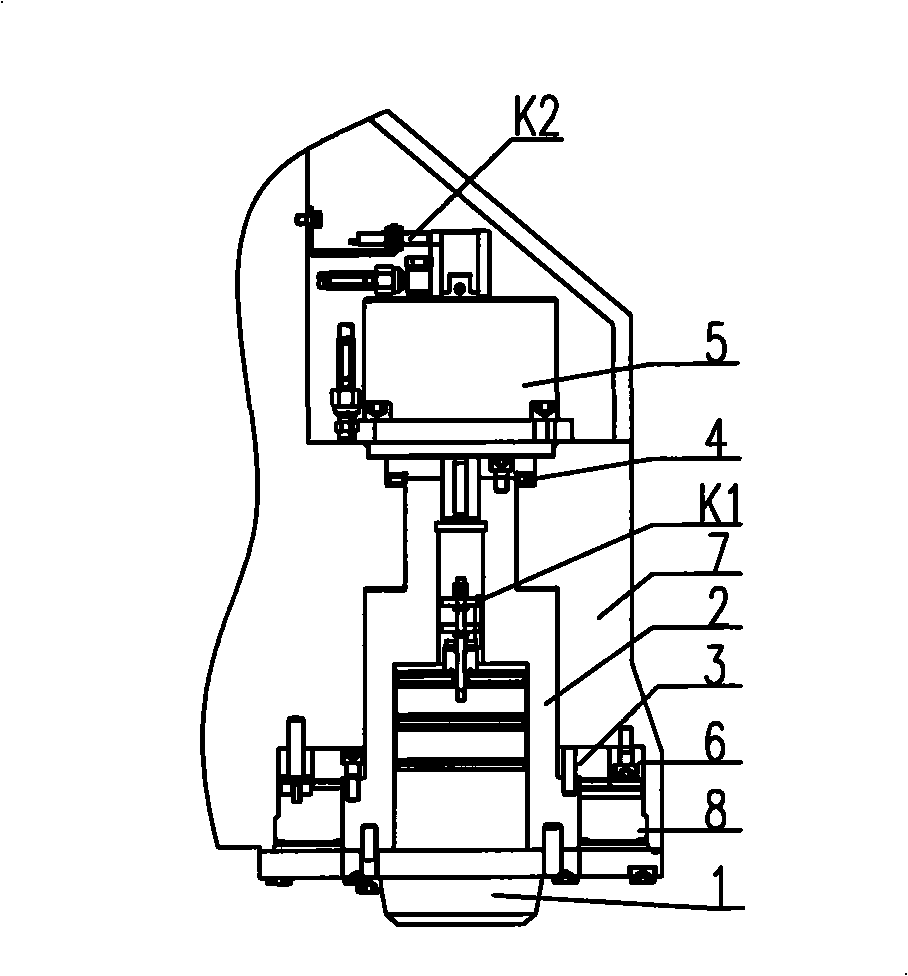

[0016] The B-axis tool holder device of the turning-milling compound machining center is installed on the B-axis of the five-axis turning-milling compound processing machine tool, and has supporting electrical, hydraulic, cooling, and pneumatic control parts that are combined with the system on the machine tool. The B-axis motor passes through The worm gear drives the incoming shaft, such as figure 1 and figure 2 As shown, it is characterized in that the turning tool, the tool for special needs and the rotating tool whose overhang length meets the requirements of the tool are separated, and are respectively set at the three-point position of the B-axis tool holder: the indexable turning tool is installed at the left end I of the B-axis tool holder device No. position; the rotary tool whose overhang length meets the requirements of the tool is set at No. II position directly in front of the B-axis tool post, which can be used for boring, milling, drilling, tapping and other pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com