Cutting machine

A technology of cutting machine and feeding mechanism, which is applied to metal processing machinery parts, driving devices, metal processing equipment, etc., can solve the problems of narrow application area, inability to cut, and large loss of cutting parts, and achieve the effect of realizing processing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

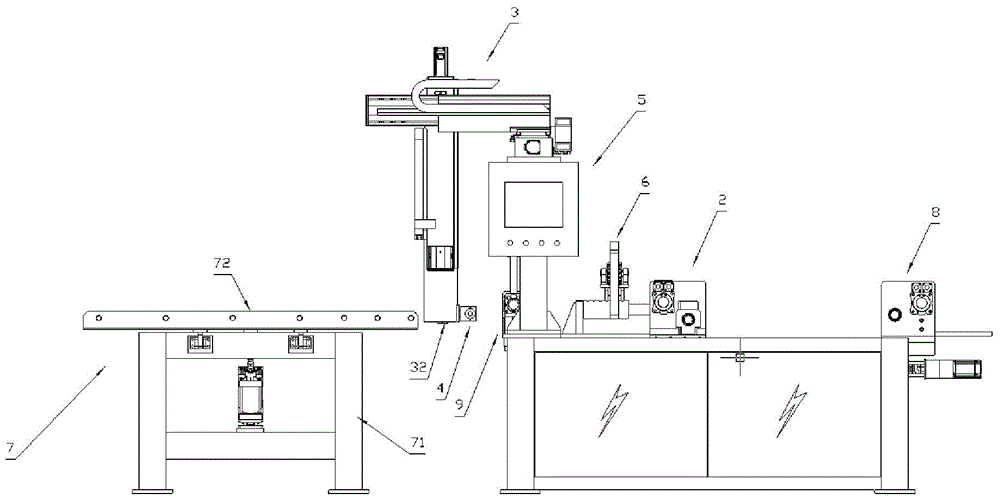

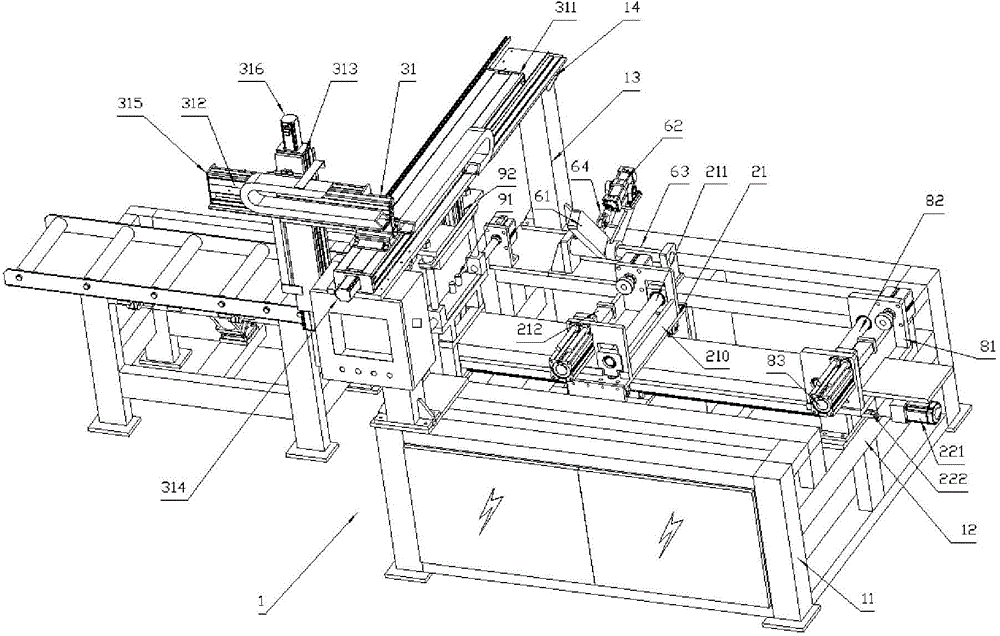

[0024] Such as figure 1 with figure 2 As shown, the cutting machine of the embodiment of the present invention includes:

[0025] Machine 1: has a three-dimensional frame 11 and a load beam 12 arranged in the three-dimensional frame, which is used for supporting the bottom of the machine;

[0026] Feeding mechanism 2: set on the machine platform 1, it has a moving mechanism 21 that drives the movement of the profile steel and a first drive mechanism 22 that drives the movement of the movement mechanism 21, and is used to drive the translation of the profile steel to transport one end of the profile steel to the cutting station;

[0027] Four-coordinate mechanism 3: installed above the cutting station, has an XYZ axis translation mechanism 31 and a cutting head installation part 32 installed on the XYZ translation mechanism 31 that can rotate 360° along the vertical plane;

[0028] Cutting head 4: installed on the cutting head installation part 32, used for cutting section s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com