Machine ram connecting mechanism

A technology of connecting mechanism and machine tool ram, applied in the field of machine tools, can solve the problems of low production efficiency, waste of resources and energy, and bulky headstock, so as to improve accuracy and service life, simplify processing technology, and reduce human factors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

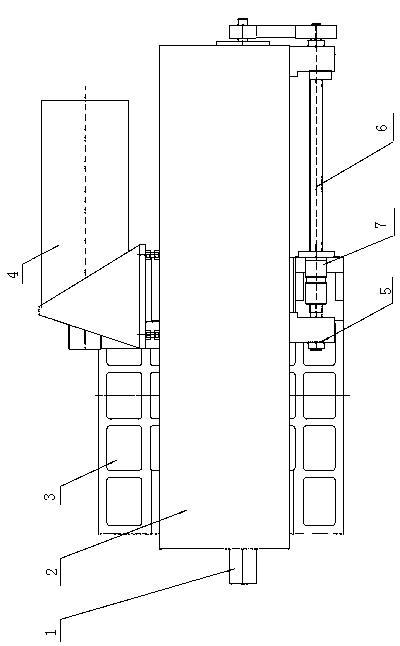

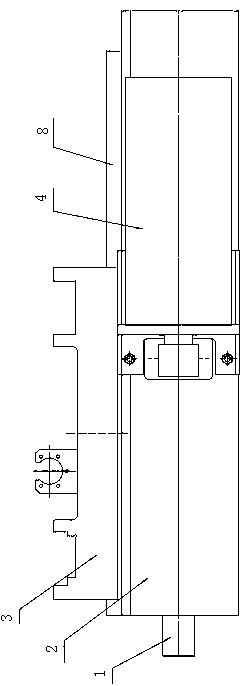

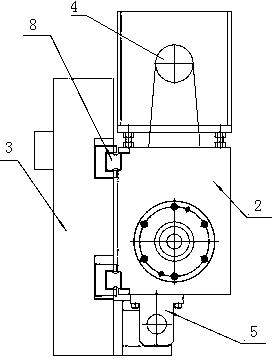

[0011] From figure 1 Shown the structural representation of the present invention, figure 2 top view of and image 3 It can be seen from the right side view that the present invention includes a sliding plate 3, a square ram 2, a main shaft 1, and a main motor 4. 8 pairs of rolling linear guide rails arranged horizontally are hung on the side of the slide plate 3, which saves the headstock part of the traditional machine tool structure, and replaces the traditional headstock with the slide plate, which greatly reduces the volume, simplifies the processing technology and saves the cost. The square ram 2 is supported by two horizontally arranged rolling linear guide rail pairs 8 parallel up and down, which not only simplifies the structure of the slide plate, saves materials, but also enables the square ram 2 and the main motor 4 on the square ram and the square slide The main shaft 1 in the pillow moves flexibly along the slide plate. There is a feed screw 6 under the squar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com