Method for machining all-metal screw pump stator

A processing method and pump stator technology, which are applied in metal processing equipment, electrochemical processing equipment, manufacturing tools, etc., can solve the problems of long processing length and large cutting amount, achieve high forming accuracy, high production efficiency, and reduce processing difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

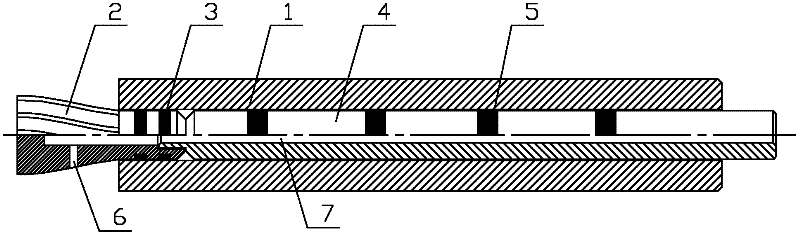

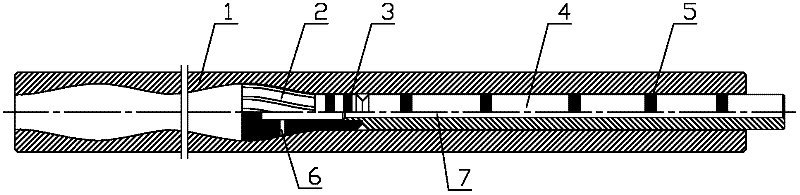

[0013] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0014] A method for processing an all-metal screw pump stator, comprising the following steps:

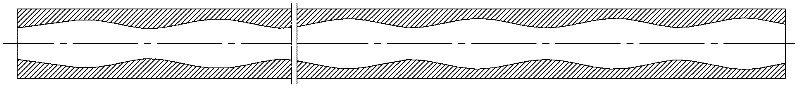

[0015] 1) The processing of the stator blank 1 is completed, and the stator blank 1 is formed with a central hole for forming the inner cavity of the stator.

[0016] 2) The inner cavity of the stator is formed by electrolytic method;

[0017] The specific steps are:

[0018] 1) Fix the stator blank 1 on the electrolytic processing equipment, and put the electrode assembly in the center hole of the stator blank 1, see figure 1 , the electrode assembly includes a processing electrode 2 and an electrode rod 4 coaxially fixed thereto;

[0019] The processing electrode 2 is provided with a forming section and a sealing section; a sealing ring 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com