High-instantaneous-energy-density electric spark high-speed milling method

An energy density, high-speed milling technology, applied in the field of mechanical processing, can solve problems such as reducing processing flexibility, achieve the effect of efficient processing and ensure processing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

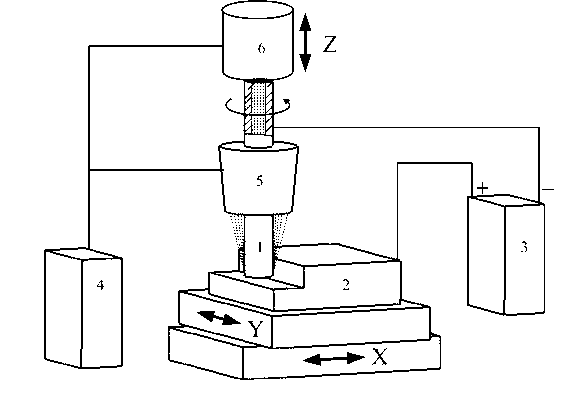

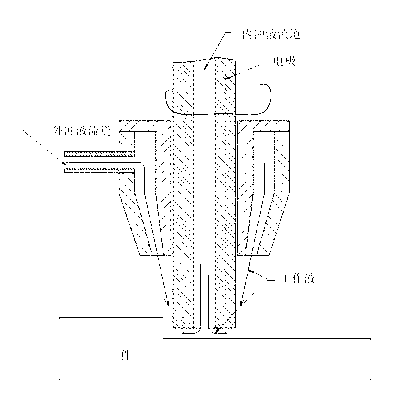

[0021] Using a machine tool with three-axis automatic servo feed and retract function, the spindle speed is 3000 r / min, the diameter of the tool electrode 1 is 10 mm, the diameter of the central flushing hole is 4 mm, and the material is high-purity graphite. The material of workpiece 2 is die steel 8407, and the pulse width is 3 ms, the pulse interval is 1 ms, the peak voltage is 80 V, and the peak current is 800 A. The working fluid is an oil-in-water emulsion with a water content of 95%. , the working fluid pressure provided by the internal flushing system is 0.5 MPa, and the outlet pressure of the working fluid provided by the external flushing system is 0.3 MPa. The machining trajectory is that the tool electrode is fed vertically downward by 5 mm, and then moves horizontally by 50 mm. A keyway structure is processed, and the material removal rate of the obtained mold steel 8407 is 8952 mm 3 / min.

Embodiment 2

[0023] Change the workpiece material to fully verify the universal applicability of high-speed arc discharge milling to different materials. The workpiece material is selected as titanium alloy (model TC4), and other processing conditions in Example 1 are kept unchanged. The material removal rate of TC4 is 14263 mm 3 / min.

Embodiment 3

[0025] Select the workpiece material as carbon steel (S45C), keep other processing conditions unchanged in Example 1, and the material removal rate of carbon steel S45C is 10127 mm 3 / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| material removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com