Method for improving surface tribology performance of M50NiL bearing steel

A technology of surface friction and bearing steel, applied in the direction of ion implantation plating, coating, metal material coating technology, etc., can solve problems such as economic loss, bad social impact, bearing wear failure, etc., to improve tribological performance, improve Effects of film-substrate adhesion and friction properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

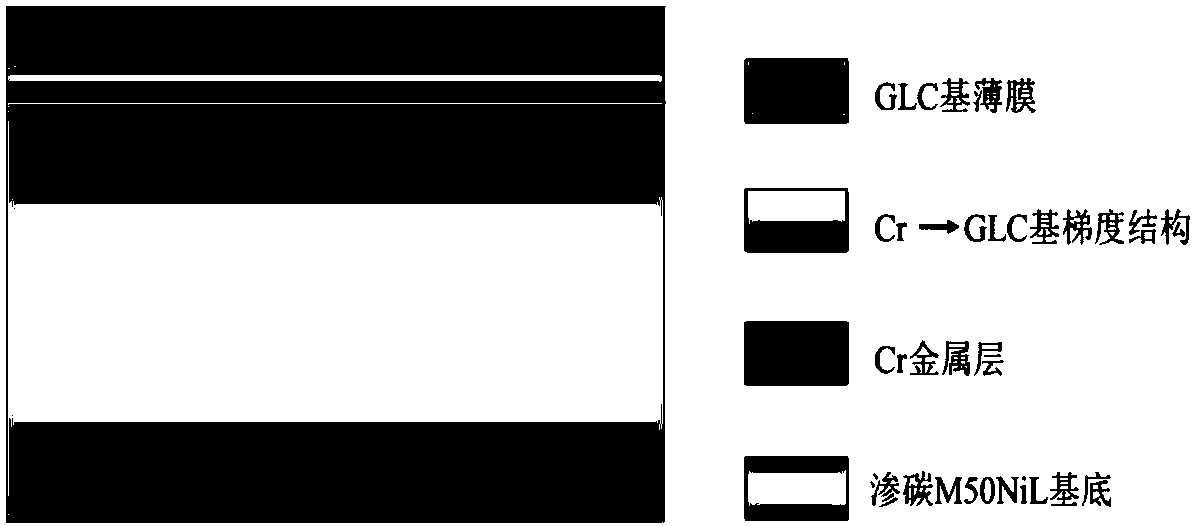

Image

Examples

Embodiment 1

[0033] 1) Vacuum pulse carburizing treatment

[0034] The surface carburizing treatment adopts the vacuum pulse carburizing method. Each pulse cycle includes a strong carburizing process, that is, the introduction of carburizing gas and a diffusion process, that is, stopping inflation and vacuuming, and the time of the diffusion process is 4 times that of the strong carburizing process. times, the carburizing temperature is 900°C, and the time is 6h. After carburizing, perform high-temperature tempering twice, the tempering temperature is about 700°C, and the holding time is about 420min;

[0035] 2) Quenching and tempering treatment

[0036] The holding temperature is 1050-1110°C, quenching after holding time for 90 minutes; cold treatment at -70°C for 60 minutes, tempering treatment at 530-550°C for 180 minutes; repeat cold treatment and tempering at -70°C once.

[0037] 3) Polishing and cleaning of M50NiL bearing steel substrate

[0038] Use 400-600, 800-1000, 1200, and ...

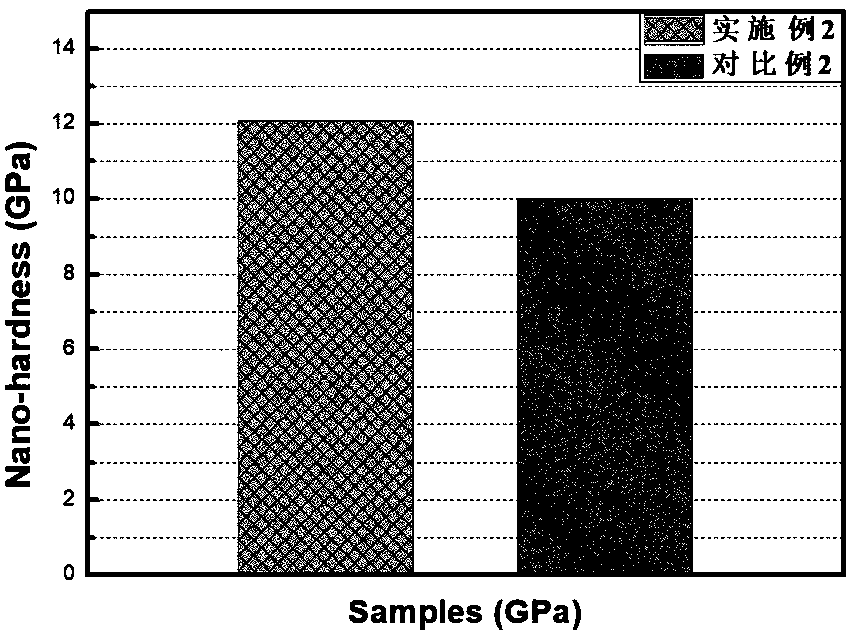

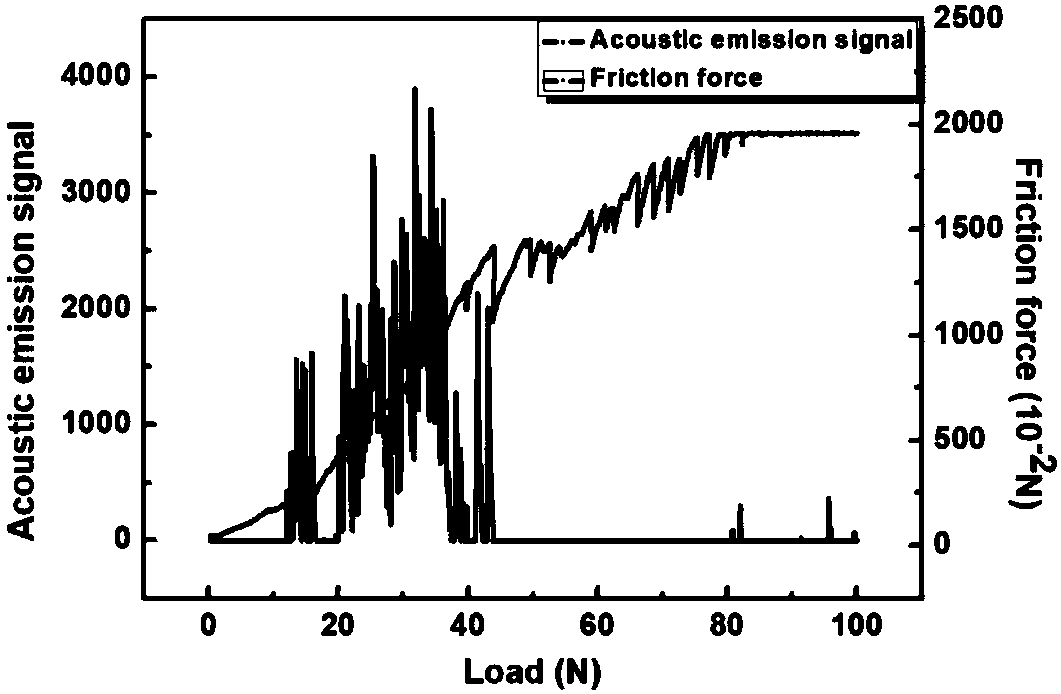

Embodiment 2

[0049] 1) Vacuum pulse carburizing treatment

[0050] The surface carburizing treatment adopts the vacuum pulse carburizing method. Each pulse cycle includes a strong carburizing process, that is, the introduction of carburizing gas and a diffusion process, that is, stopping inflation and vacuuming, and the time of the diffusion process is 4 times that of the strong carburizing process. times, the carburizing temperature is 900°C, and the time is about 6h. After carburizing, perform high-temperature tempering twice, the tempering temperature is about 700°C, and the holding time is about 420min.

[0051] 2) Quenching and tempering treatment

[0052] The holding temperature is 1050-1110°C, quenching after holding time for 90 minutes; cold treatment at -70°C for 60 minutes, tempering treatment at 530-550°C for 180 minutes; repeat cold treatment and tempering at -70°C once.

[0053] 3) Polishing and cleaning of M50NiL bearing steel substrate

[0054] Use 400-600, 800-1000, 1200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com