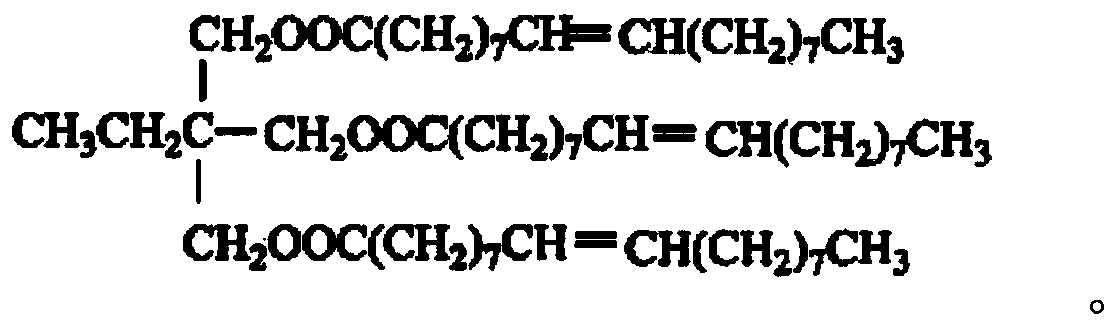

Use of trimethylolpropane oleate, trimethylolpropane oleate containing composition and use of trimethylolpropane oleate containing composition

A technology of methylolpropane oleate and lubricating oil composition, applied in the field of trimethylolpropane oleate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

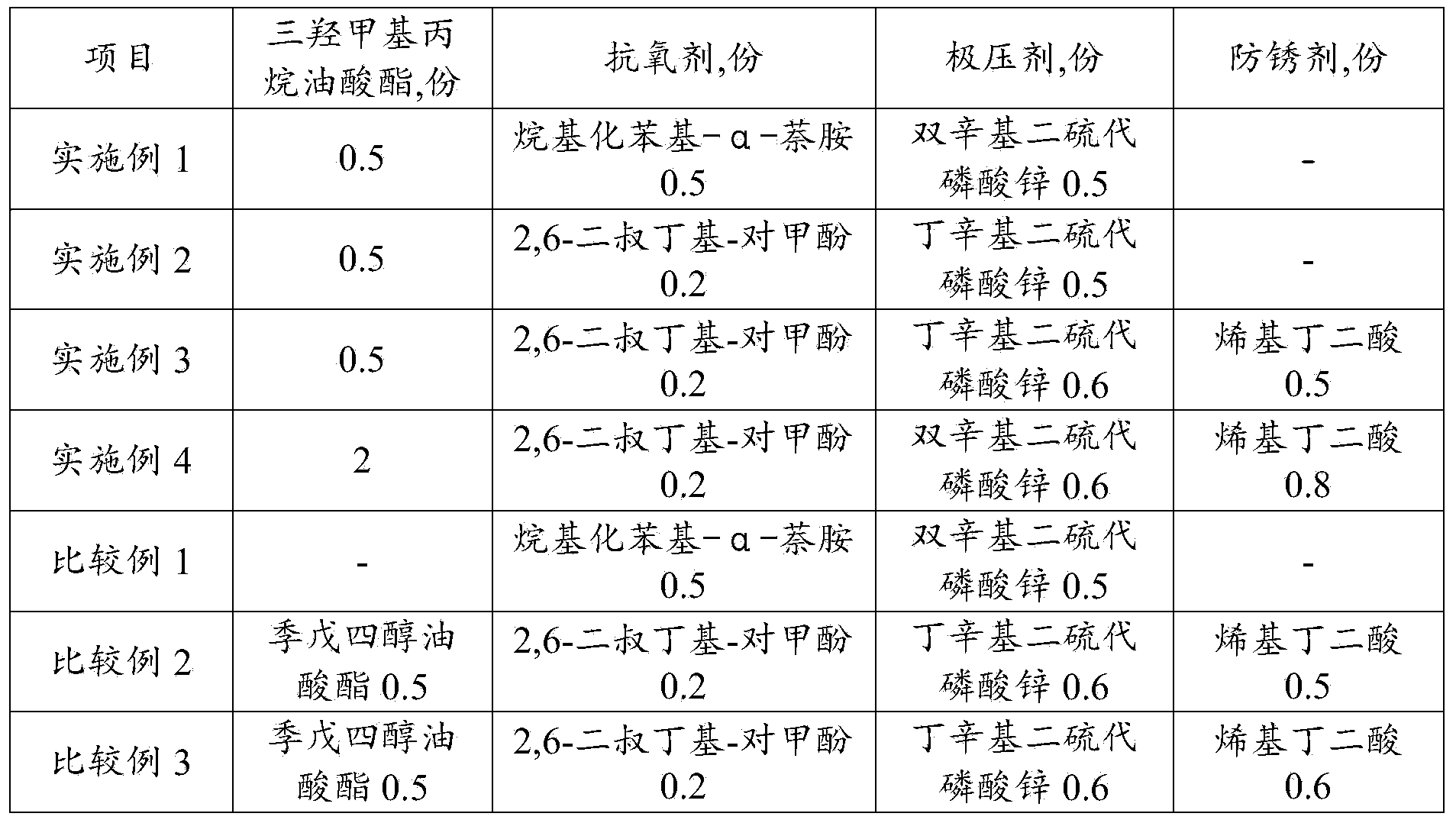

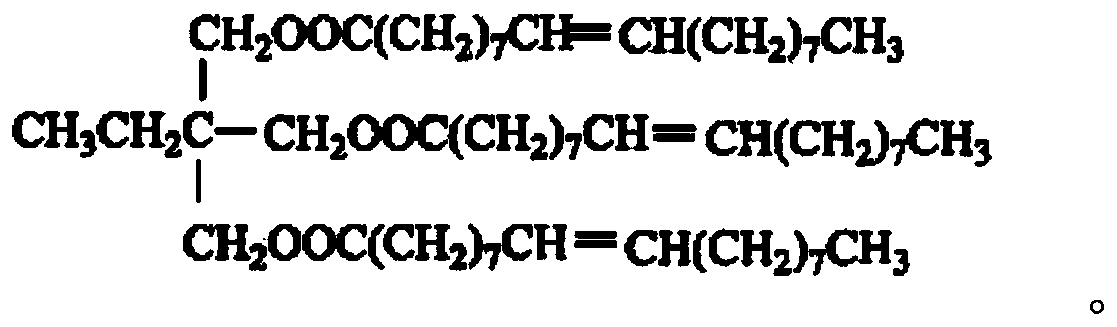

Embodiment 1~4

[0021] According to the parts by weight in Table 1, weigh the required amounts of antioxidants, extreme pressure agents, and rust inhibitors respectively, add them to 100 parts of base oil, heat and stir at 45-65°C until completely uniform, and obtain a combination thing. The types and amounts of each component in the composition are shown in Table 1 (base oil is omitted), and the properties of the oil (antirust test results) are shown in Table 2.

[0022] Among them, the liquid phase corrosion test is evaluated by GB / T11143 "Test Method for Antirust Performance of Mineral Oil Added Inhibitors in the Existence of Water", and the test conditions are distilled water for 24 hours. The damp heat test is evaluated by GB / T2361 "Damp Heat Test Method for Antirust Grease", the test condition is No. 45 steel sheet, 49±1°C, grade A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com