WS2/MoS2 solid lubrication multilayer film and method for making same

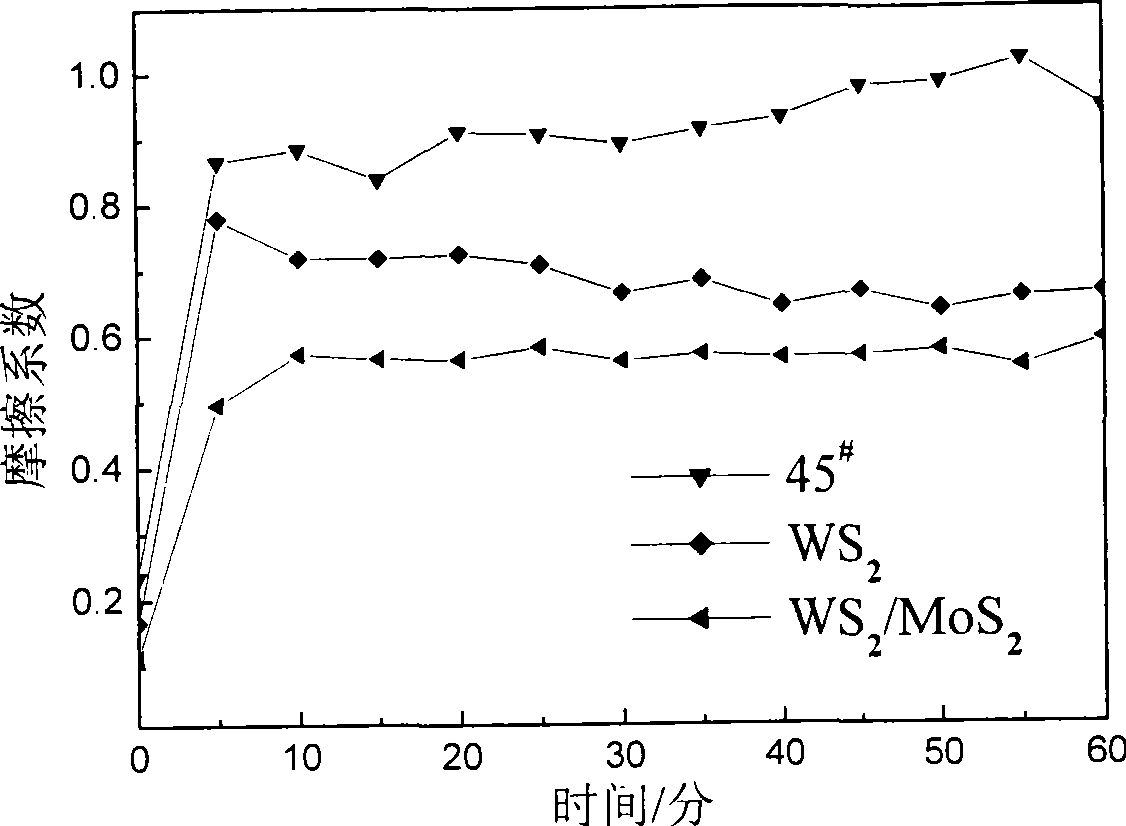

A solid lubricating, multi-layer film technology, applied in lubricating compositions, engine lubrication, solid diffusion coating, etc. problem, to achieve the effect of good nanomechanical properties, compact structure and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) The substrate is quenched, the hardness is HRC55, and the surface roughness is 0.8 μm;

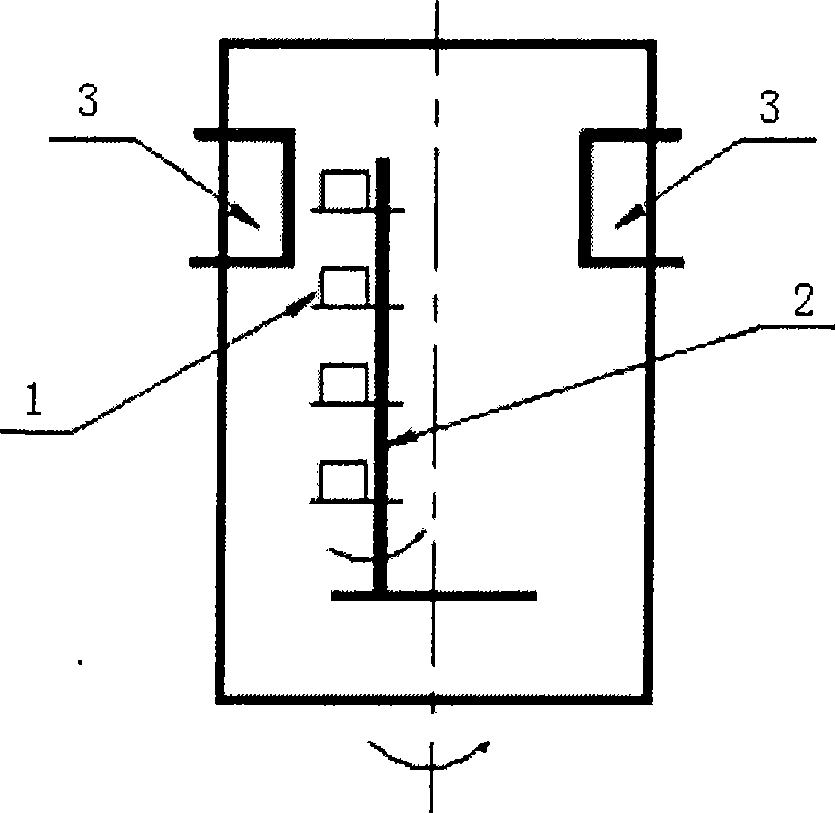

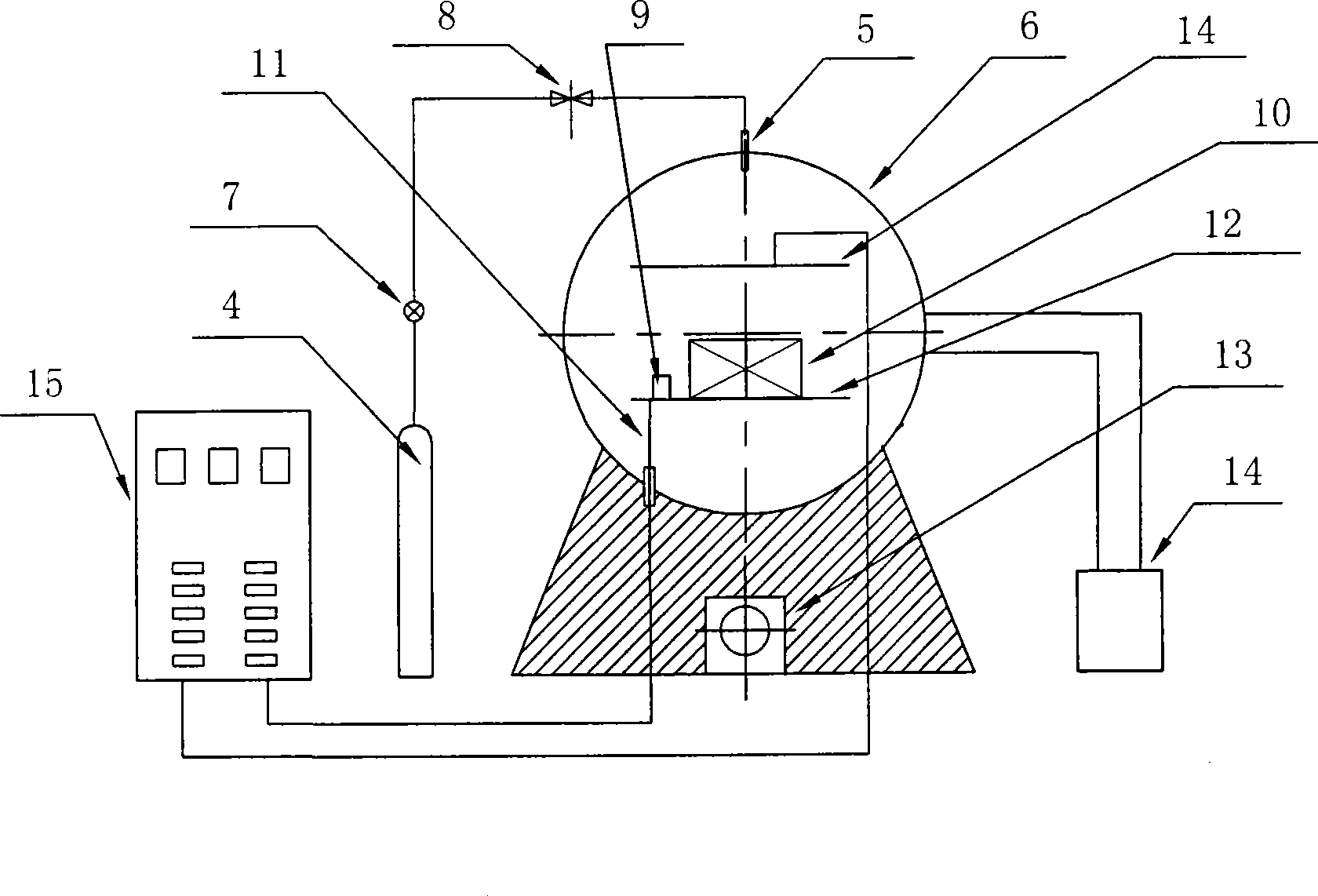

[0055] (2) The target material adopts a W target with a purity of 90-99.95% and a Mo target with a purity of 90-99.95%. In a double-target RF sputtering device, W / Mo is made by alternately depositing a W layer and a Mo layer on the substrate. Multi-layer film, when the vacuum degree in the furnace reaches 2.5×10 -3 At this time, the inert gas argon with a purity of 99.999% was introduced, and the pressure was controlled at 1.0 Pa to start sputtering. The current is 1.0A; the double-target radio frequency sputtering alternately deposits W layers and Mo layers to form a W / Mo multilayer film. The thickness of the film is determined by the residence time and deposition rate of the substrate before the target in the double-target radio frequency sputtering alternate deposition steps. Control, the target distance is 60mm, when depositing the W layer, the residence time of the substra...

Embodiment 2

[0075] (1) The substrate is quenched, the hardness is HRC55, and the surface roughness is 0.8 μm;

[0076] (2) The target material adopts a W target with a purity of 90-99.95% and a Mo target with a purity of 90-99.95%. In a double-target RF sputtering device, W / Mo is made by alternately depositing a W layer and a Mo layer on the substrate. Nano multilayer film, when the vacuum degree in the furnace reaches 2.75×10 -3 Pa, the inert gas argon with a purity of 99.999% was introduced, and the pressure was controlled at 1.1 Pa to start sputtering. The current is 1.5A; the double target radio frequency sputtering alternately deposits W layer and Mo layer to make W / Mo nanometer multilayer film thickness by the residence time and deposition rate of substrate in front of the target in the double target radio frequency sputtering alternate deposition step To control, the target distance is 70mm. When depositing the W layer, the residence time of the substrate in front of the W target ...

Embodiment 3

[0095] (1) The substrate is quenched, the hardness is HRC55, and the surface roughness is 0.8 μm;

[0096] (2) The target material adopts a W target with a purity of 90-99.95% and a Mo target with a purity of 90-99.95%. In a double-target RF sputtering device, W / Mo is made by alternately depositing a W layer and a Mo layer on the substrate. Nano multilayer film, when the vacuum degree in the furnace reaches 3.0×10 -3 Pa, the inert gas argon with a purity of 99.999% was introduced, and the pressure was controlled at 1.2 Pa to start sputtering. The current is 2A; the double-target radio frequency sputtering alternately deposits W layers and Mo layers to make a W / Mo nano-multilayer film. The thickness of the film is determined by the residence time and deposition rate of the substrate in front of the target in the double-target radio frequency sputtering alternate deposition steps. Control, the target distance is 80mm, when depositing the W layer, the residence time of the subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com