Graphene oxide modified nano additive and application thereof to lubricating oil

A nano-additive, graphene technology, applied in the direction of additives, petroleum industry, lubricating composition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step (1) Preparation of GO-OH: 100mgGO, 60mL thionyl chloride (SOCl 2 ) and 1.5mL N, N-dimethylformamide (DMF) under the protection of argon, 70 o C reflux reaction for 24h. After the reaction, excess SOCl 2 and the solvent were removed by distillation under reduced pressure. The remaining solid did not need further purification, and was directly flashed with anhydrous ethylene glycol (80 mL) at 80 o C reacted for 24h. The reacted suspension was filtered with suction and washed several times with anhydrous tetrahydrofuran (THF). The remaining solids were vacuum 40 o C dried overnight.

[0032] Step (2) Preparation of graphene oxide-poly-3-ethyl-3-hydroxymethyloxetane (GO-PPHO): Add 100 mg GO-OH to 50 mL CH under the protection of argon 2 Cl 2 and 2mL boron trifluoride diethyl ether (BF 3 ·OEt 2 ), sonicate for 20min. Then 20mL of 3-ethyl-3-hydroxymethyloxetane (EHO) was added dropwise into the reaction system through the injection pump over 2h. The reaction ...

Embodiment 2

[0035] Steps (1) (2) are the same as in Embodiment 1.

[0036] Step (3) Preparation of graphene oxide-polymer phosphate esters (GO-PPEs): 100 mg GO-PEHO, 4 mL diphenyl phosphate chloride and 20 mg anhydrous magnesium chloride were added to 50 mL toluene under argon protection. The reaction mixture was at 110 o C stirred the reaction for 15h. The solvent was removed by filtration and washed three times with toluene. After drying, it was redispersed in deionized water, filtered, washed several times, and finally washed three times with ethanol. Vacuum 60 o C dried overnight.

Embodiment 3

[0038] Steps (1) (2) are the same as in Embodiment 1.

[0039] Step (3) Preparation of graphene oxide-polymer phosphate esters (GO-PPEs): 100mg GO-PEHO, 4mL diphenyl phosphate chloride and 20mg anhydrous aluminum chloride were added to 50mL toluene under the protection of argon . The reaction mixture was at 90 o C stirred the reaction for 15h. The solvent was removed by filtration and washed three times with toluene. After drying, it was redispersed in deionized water, filtered, washed several times, and finally washed three times with ethanol. Vacuum 60 o C dried overnight.

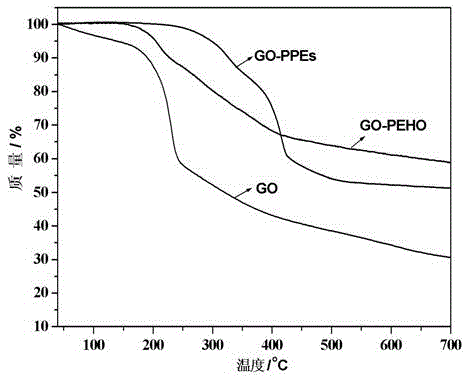

[0040] Thermal Stability Evaluation

[0041] Thermal stability was determined by STA449C Jupitersimultaneous TG-DSC. Put the raw material GO in Example 1, the intermediate product GO-PEHO, and the product GO-PPEs 5 mg each into the sample pool, and the test temperature is from 20 to 800 o C, the rate of temperature increase is 10 o C / min, measured under nitrogen atmosphere. The results are atta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com