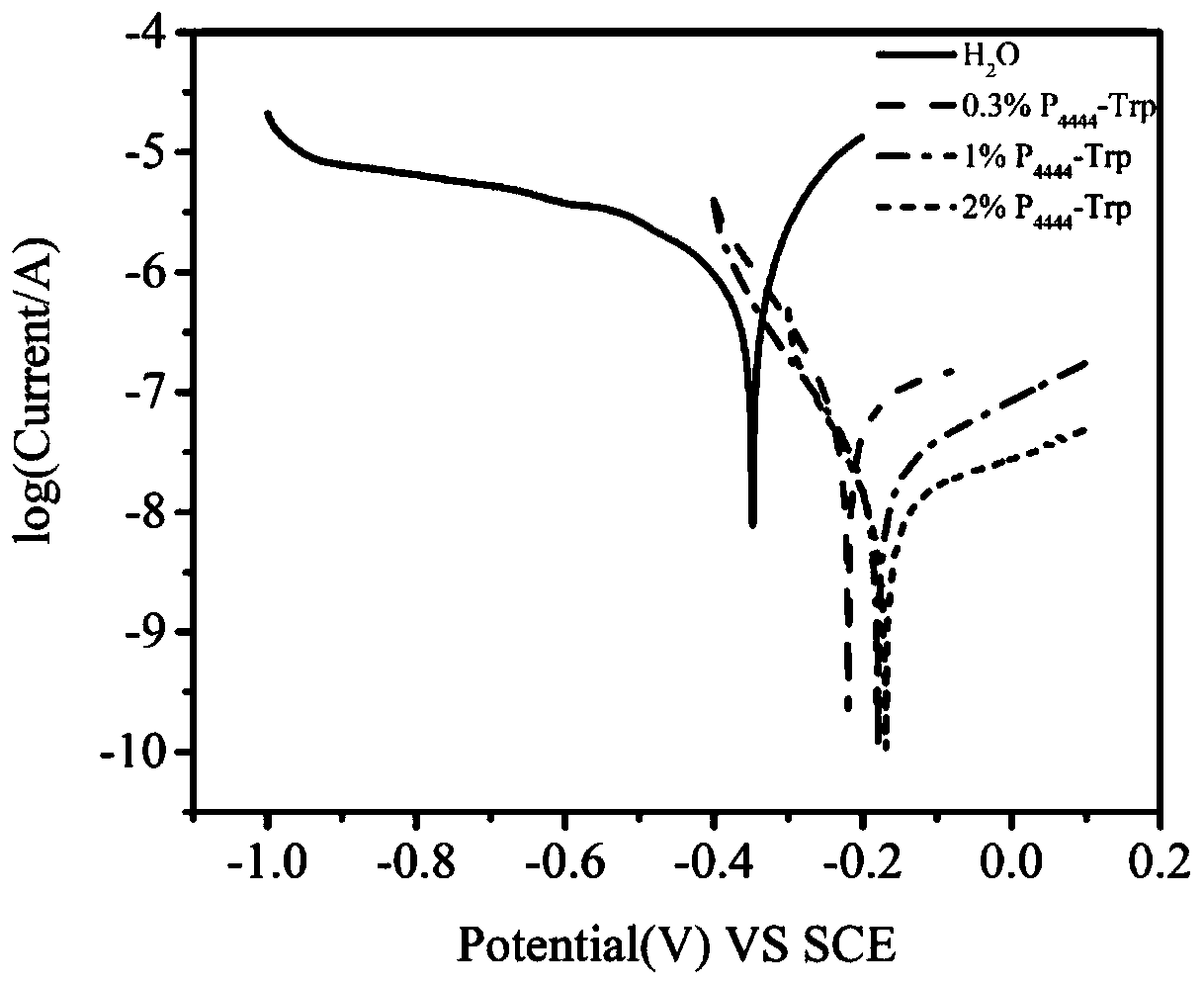

Amino acid ionic liquid water-based additive and preparation method and application thereof

An ionic liquid and amino acid technology, applied in the field of amino acid ionic liquid water-based additives and their preparation, can solve problems such as environmental pollution, and achieve the effects of environmental friendliness, good solubility, and excellent anti-friction and anti-wear properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

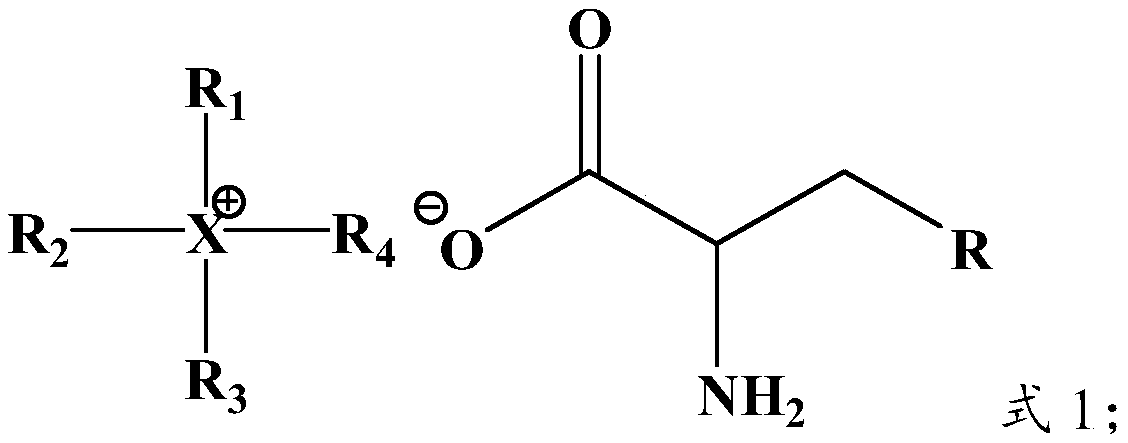

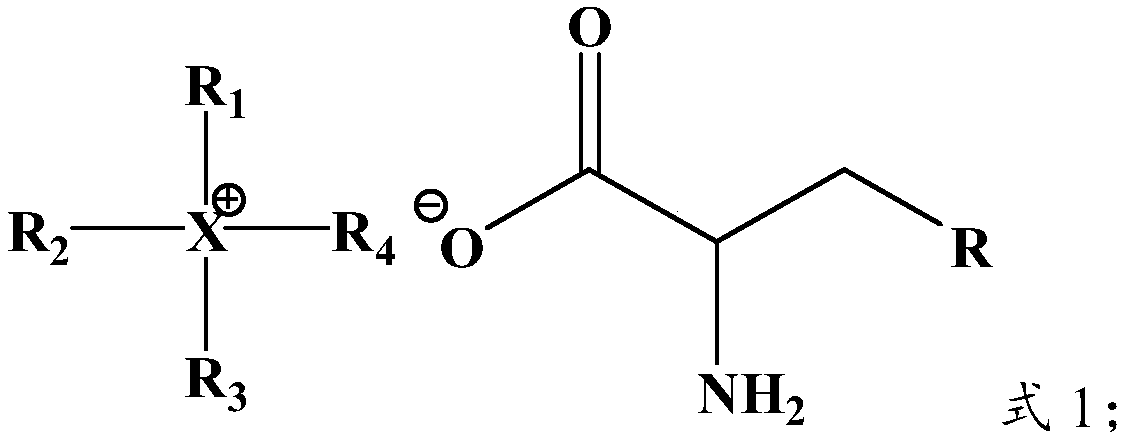

[0037] The present invention also provides a preparation method of the amino acid ionic liquid water-based additive described in the above technical solution, comprising the following steps:

[0038] mixing tetraalkyl hydroxide, amino acid and water, and performing an acid-base neutralization reaction to obtain the amino acid ionic liquid water-based additive;

[0039] The amino acids include tryptophan, cysteine, lysine, phenylalanine, serine, methionine or histidine;

[0040] The number of carbons in the alkyl group in the tetraalkyl hydroxide is independently 1-18;

[0041] The tetraalkyl hydroxide is tetraalkyl phosphorus hydroxide or tetraalkyl ammonium hydroxide.

[0042] In the present invention, unless otherwise specified, the raw materials used are conventional commercially available products in this field.

[0043] In the present invention, the molar ratio of the tetraalkyl hydroxide to the amino acid is preferably 1:1˜1:1.4, more preferably 1:1.

[0044] The pres...

Embodiment 1

[0054] Tetrabutylphosphorus hydroxide and histidine were weighed at a molar ratio of 1:1, dissolved in water, and stirred at room temperature for 24 hours. After the reaction was finished, the solvent was evaporated under reduced pressure, the solid was dissolved in dichloromethane, washed with water to remove unreacted raw materials, then the organic phase was dried, and the solvent was evaporated under reduced pressure to obtain a white amino acid ionic liquid water-based additive (structural formula shown in formula 2 ).

[0055]

[0056] Among them, the calculated value of the mass spectrum of the cation part: 259.2549, the measured value: 259.2540, the calculated value of the mass spectrum of the anion part: 154.0617, the measured value: 154.0620.

Embodiment 2

[0058] Weigh tetrabutylphosphorus hydroxide and serine in a molar ratio of 1:1, dissolve in water, and react with stirring at room temperature for 24 hours. After the reaction was finished, the solvent was evaporated under reduced pressure, the solid was dissolved in dichloromethane, washed with water to remove unreacted raw materials, then the organic phase was dried, and the solvent was evaporated under reduced pressure to obtain a white amino acid ionic liquid water-based additive (structural formula is shown in formula 3 ).

[0059]

[0060] Among them, the calculated value of the mass spectrum of the cation part: 259.2549, the measured value: 259.2541, the calculated value of the mass spectrum of the anion part: 104.0348, the measured value: 104.0351.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com