Preparation method of graphene functional lubricating oil

A technology of lubricating oil and graphene, which is applied in the field of lubricating oil to achieve good dispersion stability, high carrying capacity and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

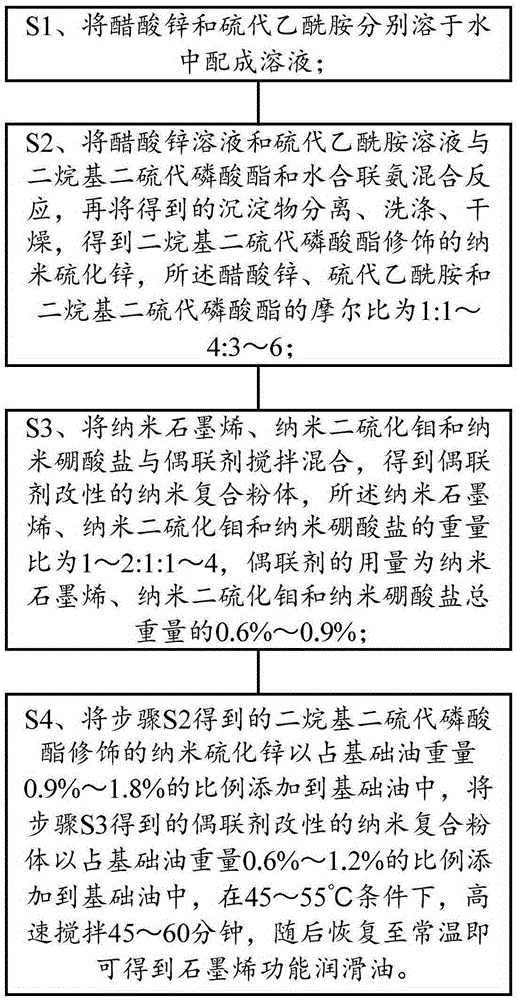

[0018] A preparation method for graphene functional lubricating oil, comprising the following steps:

[0019] S1, zinc acetate and thioacetamide are dissolved in water respectively to form a solution;

[0020] S2. Mix zinc acetate solution and thioacetamide solution with dialkyl phosphorodithioate and hydrazine hydrate to react, then separate, wash and dry the obtained precipitate to obtain dialkyl phosphorodithioate modification Nano zinc sulfide, the molar ratio of zinc acetate, thioacetamide and dialkyl dithiophosphate is 1:1~4:3~6;

[0021] S3. Stirring and mixing nano-graphene, nano-molybdenum disulfide and nano-borate with a coupling agent to obtain a nano-composite powder modified by a coupling agent, the nano-graphene, nano-molybdenum disulfide and nano-borate The weight ratio is 1~2:1:1~4, and the consumption of coupling agent is 0.6%~0.9% of the total weight of nano graphene, nano molybdenum disulfide and nano borate;

[0022] S4. Add the nano-zinc sulfide modified...

Embodiment 1

[0030] The preparation method of the functional lubricating oil of the present embodiment comprises the following steps:

[0031] S11, dissolving zinc acetate and thioacetamide in water respectively to form a solution;

[0032] S12. Mixing zinc acetate solution and thioacetamide solution with dioctyl phosphorodithioate and hydrazine hydrate for reaction, wherein the molar ratio of zinc acetate, thioacetamide and dioctyl phosphorodithioate is 1 : 1: 3, hydrazine hydrate is excess, the reaction temperature is 90 ° C, the reaction time is 2 hours, and then the obtained precipitate is centrifuged, and then the precipitate is washed with deionized water and absolute ethanol, and then the precipitate is in Dried in a vacuum oven to obtain nano-zinc sulfide modified by dioctyl dithiophosphate;

[0033] S13. Stirring and mixing nano-graphene particles (embedded with carbon spheres with a particle size of 85 nanometers), nano-molybdenum disulfide and nano-calcium borate with coupling ...

Embodiment 2

[0036] The preparation method of the functional lubricating oil of the present embodiment comprises the following steps:

[0037] S21, dissolving zinc acetate and thioacetamide in water respectively to form a solution;

[0038] S22. Mixing zinc acetate solution and thioacetamide solution with dioctyl phosphorodithioate and hydrazine hydrate for reaction, wherein the molar ratio of zinc acetate, thioacetamide and dioctyl phosphorodithioate is 1 : 4: 6, hydrazine hydrate is excessive, the reaction temperature is 100 ° C, the reaction time is 3 hours, and then the obtained precipitate is centrifuged, and then the precipitate is washed with deionized water and absolute ethanol, and then the precipitate is in Dried in a vacuum oven to obtain nano-zinc sulfide modified by dioctyl dithiophosphate;

[0039] S23. Stirring and mixing nano-graphene particles (embedded with carbon spheres with a particle size of 95 nanometers), nano-molybdenum disulfide and nano-calcium borate and coupli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com