Preparation method for metal material surface antifriction and antiwear nano-composite film

A metal material and nano-composite technology is applied in the field of preparation of anti-friction and anti-wear nano-composite films on the surface of metal materials. Large contact angle, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

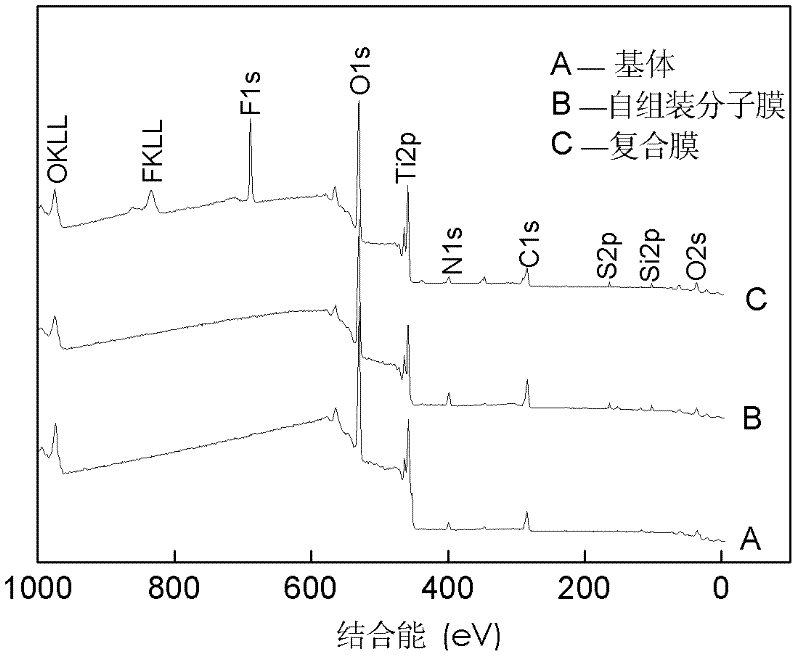

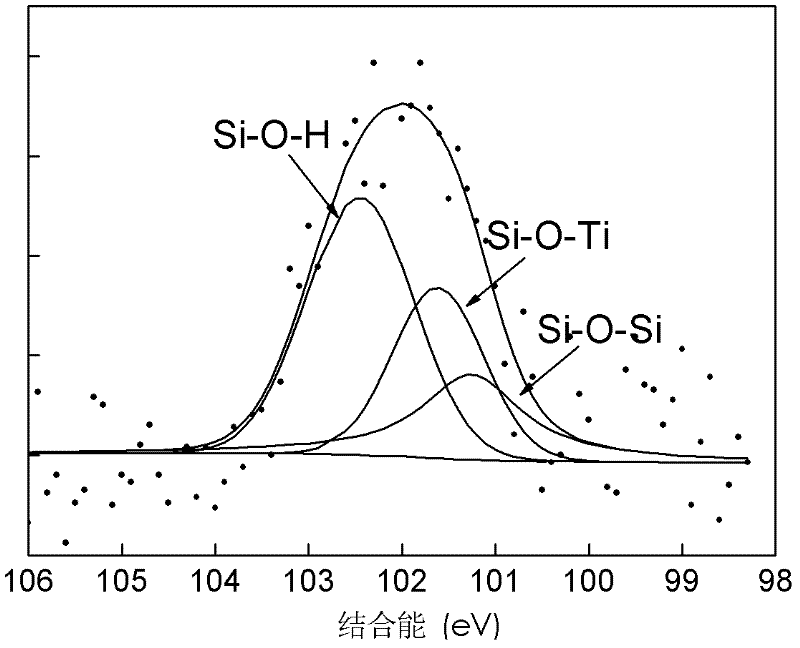

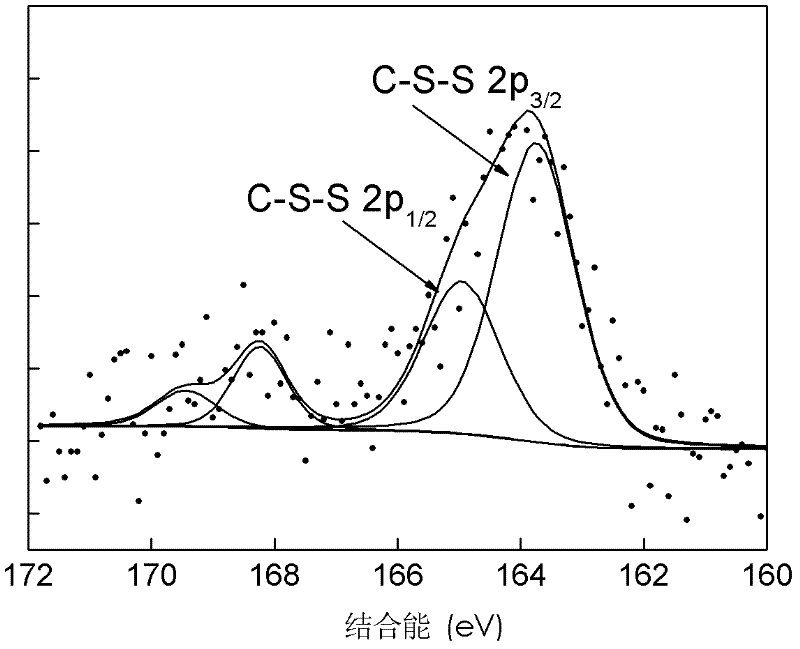

[0042] The metal material is a Ti-6Al-4V titanium alloy plate with a size of 50×30×1.5 (mm). The composite process of self-assembled molecular film technology and organic coating technology is used in turn to prepare a special surface on the surface of the Ti-6Al-4V titanium alloy material. The anti-friction and anti-wear nanocomposite film specifically includes the following steps and process conditions:

[0043] Step 1: Preparation of self-assembled molecular film on the surface of Ti-6Al-4V titanium alloy material

[0044] (1) Surface pretreatment of Ti-6Al-4V titanium alloy material

[0045]Use 120#, 360#, 800#, 1200#, 1500#, 2000# sandpaper to polish the Ti-6Al-4V titanium alloy material, put it in acetone solution and ultrasonically clean it for 10 minutes to remove oil stains, take it out and dry it;

[0046] (2) Preparation of self-assembly solution

[0047] The solvent of the self-assembly solution is prepared by ethanol and distilled water at a volume ratio of 9:1,...

Embodiment 2

[0062] The metal material is a 7075 aluminum alloy plate with a size of 50×30×1.5 (mm). A composite process of self-assembled molecular film technology and organic coating technology is used in turn to prepare a nanocomposite film with anti-friction and anti-wear properties on the surface of the 7075 aluminum alloy material. , specifically including the following steps and process conditions:

[0063] Step 1: Preparation of self-assembled molecular film on the surface of 7075 aluminum alloy material

[0064] (1) Surface pretreatment of 7075 aluminum alloy material

[0065] Grind the 7075 aluminum alloy workpiece with 120#, 360#, 800#, 1200#, 1500#, 2000# sandpaper, put it in acetone solution and ultrasonically clean it for 10 minutes to remove oil stains, take it out and dry it;

[0066] (2) Preparation of self-assembly solution

[0067] The solvent of self-assembly solution is prepared by ethanol and distilled water volume ratio 8: 2, and solute is 3-mercaptopropyltrimethox...

Embodiment 3

[0079] The metal material is NdFeB permanent magnet material, with a size of 10×10×4 (mm). A composite process of self-assembled molecular film technology and organic coating technology is used in turn to prepare a nanocomposite film with anti-friction and anti-wear properties on the surface of NdFeB permanent magnet material. , specifically including the following steps and process conditions:

[0080] Step 1: Preparation of self-assembled molecular film on the surface of NdFeB permanent magnet material

[0081] (1) Surface pretreatment of NdFeB permanent magnet materials

[0082] Use 120#, 360#, 800#, 1200#, 1500#, 2000# sandpaper to polish the surface of NdFeB permanent magnet material, put it in acetone solution and ultrasonically clean it for 10 minutes to remove oil stains, take it out and dry it;

[0083] (2) Preparation of self-assembly solution

[0084] The solvent of self-assembly solution is formulated by ethanol and distilled water volume ratio 9: 1, and solute i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com