Halogen-free choline chelated boron ionic liquid lubricating additive and application thereof

A technology of lubricating additives and ionic liquids, used in additives, lubricating compositions, petroleum industry, etc., can solve the problems of rising friction coefficient, low friction coefficient, lubricant loss, etc., and achieve excellent anti-friction and anti-wear properties, excellent anti-corrosion Sexual, Environmentally Friendly Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The preparation method of halogen-free choline chelated boron ionic liquid lubricating additive comprises the following steps:

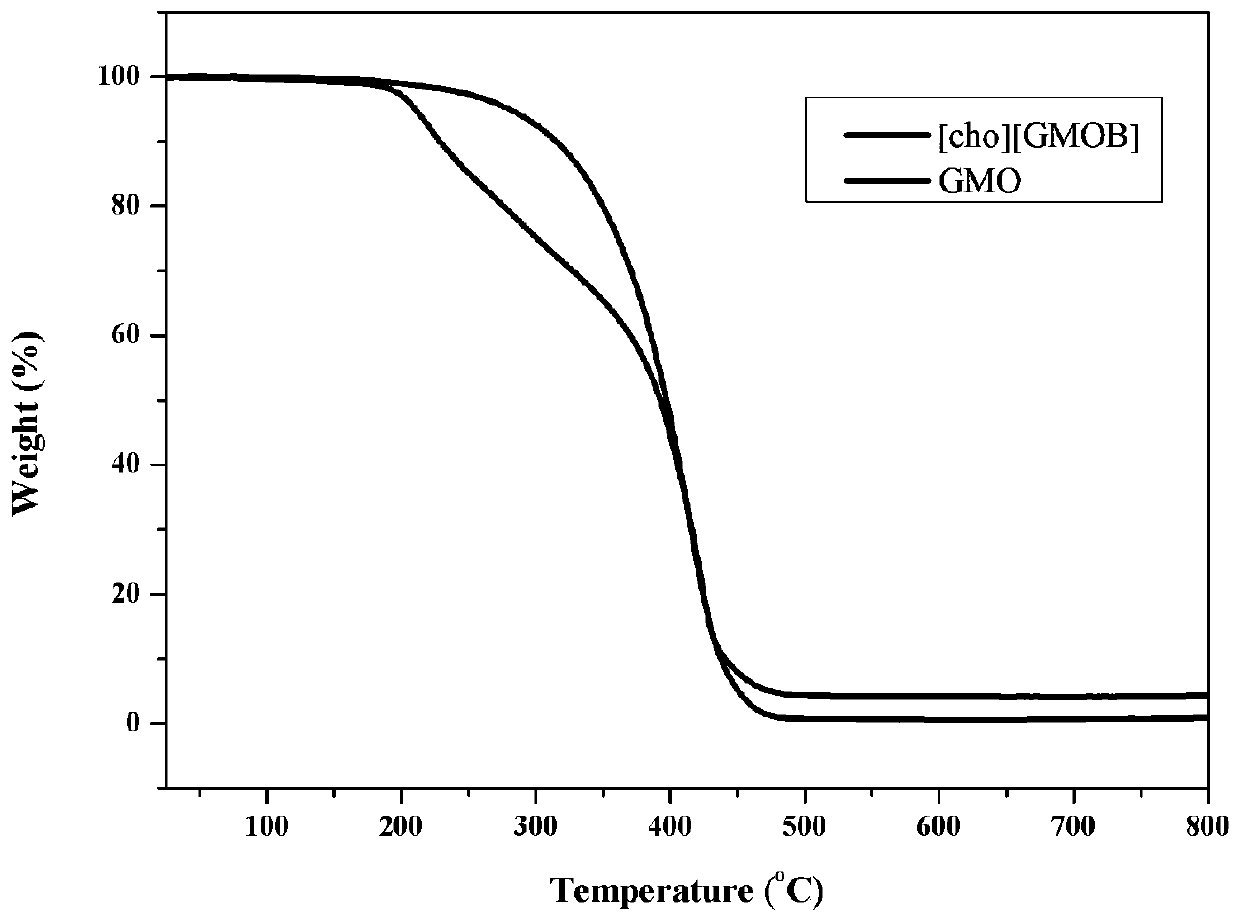

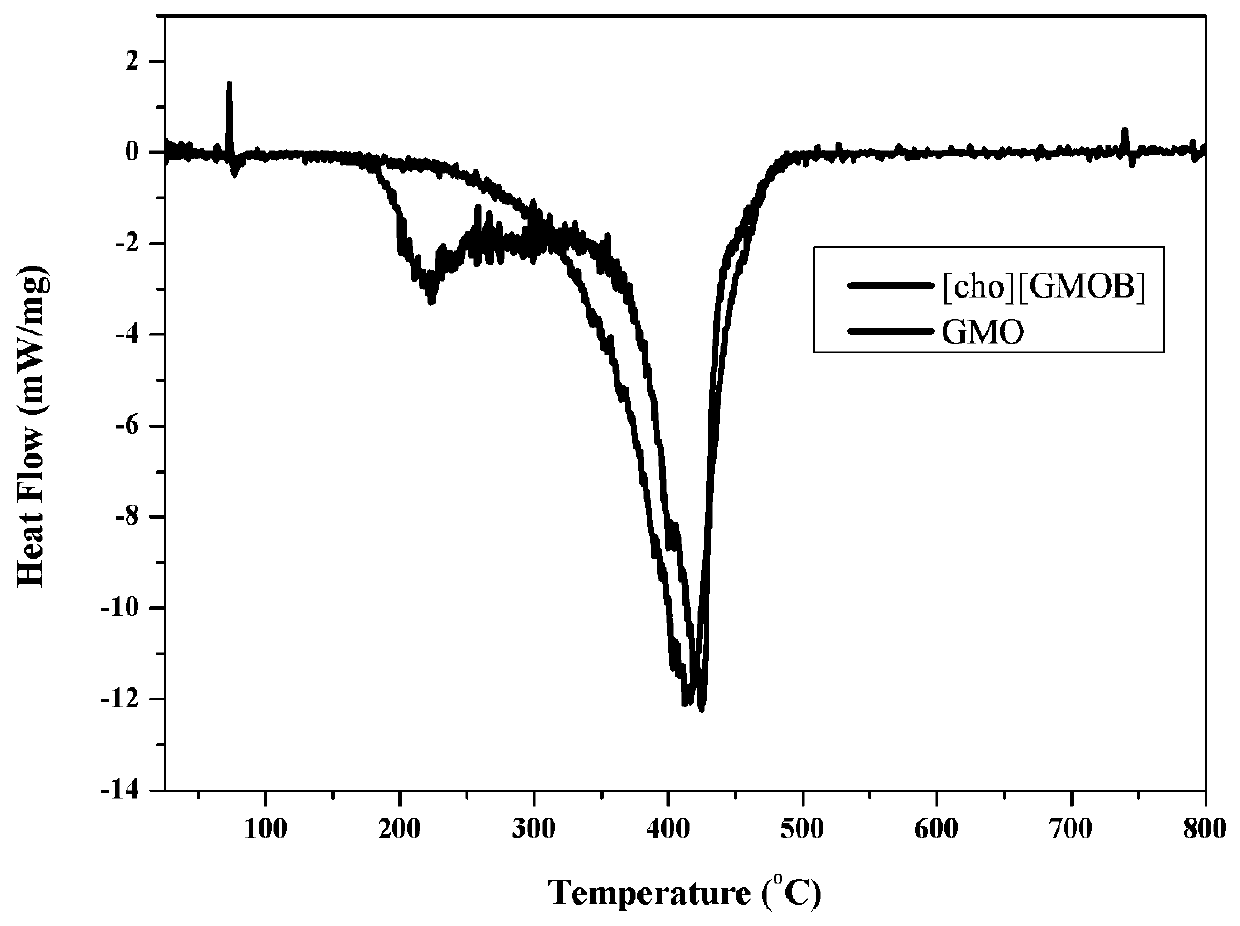

[0017] (1) Weigh 1.236g (0.02mol) of boric acid and add it to 14.2616g (0.04mol) of glycerol monooleate. Stir continuously at 80°C for 3h, and the mixture changes from colorless to light yellow.

[0018] (2) Add 5.2683g (0.02mol) choline hydroxide aqueous solution to the mixture obtained in step (1), and continue to stir and react for 3h at 120°C. As the reaction proceeds, the water is continuously evaporated, and the mixture gradually changes from light yellow It is dark brown, then vacuum-dried at 70°C for 48 hours, and finally a dark brown viscous liquid product [cho][GMOB] is obtained. [cho][GMOB] uses choline hydroxide as a cation and diglyceride monooleate to chelate boron is an anion, the chemical structural formula is shown in formula (2),

[0019]

[0020] The molar ratio of choline hydroxide aqueous solution to diglycerol monoole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com