Preparation method of choline eutectic solvent and application of choline eutectic solvent in extraction of flavonoid compounds

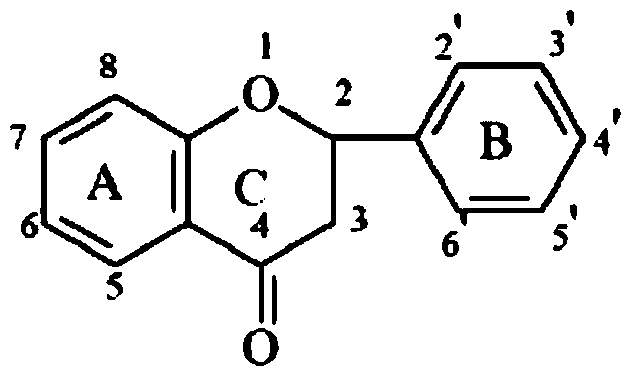

A technology of flavonoids and deep eutectic solvents, which is applied in the field of new extraction technology of flavonoids natural products, can solve the problems of toxic residues, environmental pollution, etc., and achieve the effects of high extraction rate, reduced extraction time, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

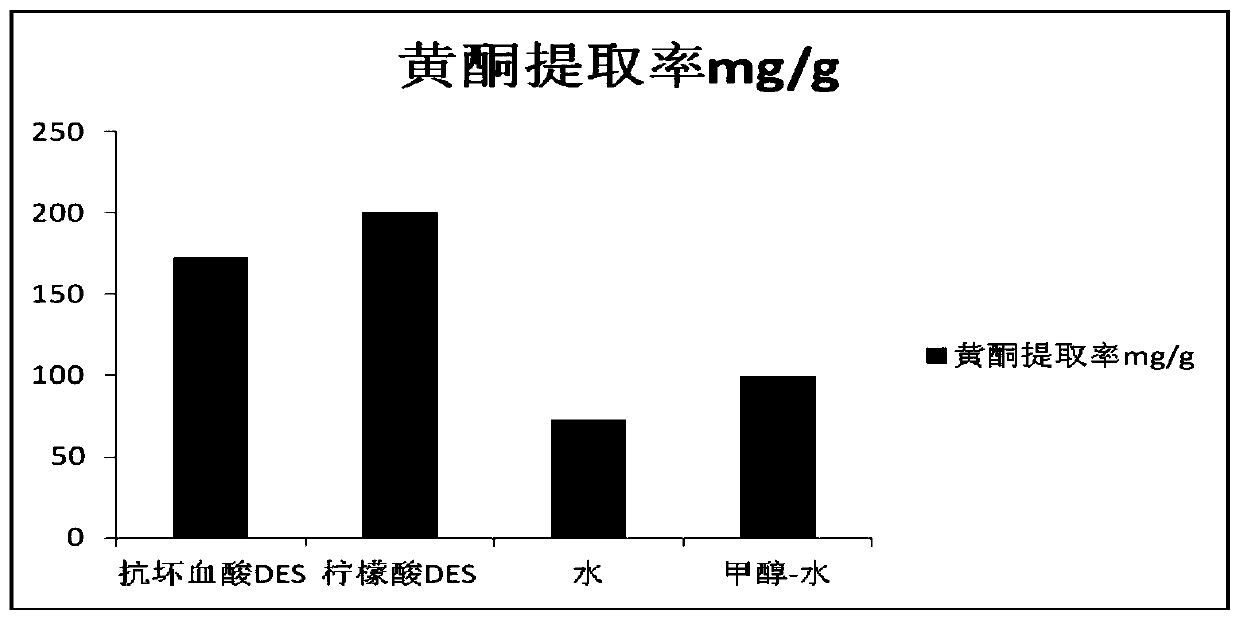

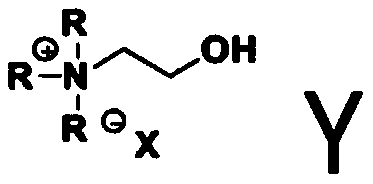

[0027] Take by weighing 352g ascorbic acid and 140g choline chloride and place in a magnetic stirrer, add 10ml deionized water to initiate the reaction, stir until the product in the flask is a viscous colorless liquid, and stop, and the viscous colorless liquid is mixed with a dry The powdered and sieved camellia oleifera powder was mixed with a material-to-liquid ratio of 10:1 and placed in an ultrasonic cleaning machine for ultrasonic-assisted extraction 4 times, 30 min each time. After filtering out the filter residue, the filtrate extract was centrifuged at 10000r / min for 40min, then filtered, and the filtrate was dried and stored to determine the extraction rate of flavonoids in tea leaf powder.

Embodiment 2

[0029] Take by weighing 10g of caffeic acid and 10g of choline chloride, add 10ml of water in a magnetic stirrer to initiate the reaction, stir and stop when the product in the flask is a viscous colorless liquid, take an appropriate amount of dry, pulverized, and sieved oil tea powder in 1: 10 Ratio of material to liquid Add the above viscous colorless liquid and mix well, then put it in a flask and extract it in an ultrasonic cleaning machine for 4 times, each time for 20 minutes. After filtering out the filter residue, the filtrate extract was centrifuged at a speed of 10000r / min for 40min and then filtered, and the filtrate was stored dry and the extraction rate of flavonoids in tea leaf powder was determined.

Embodiment 3

[0031] Take by weighing 192g citric acid and 140g choline chloride, add 10ml water in the magnetic stirrer and initiate reaction, stir and stop when the product in the flask is viscous shape colorless liquid, take dry, pulverize, sieve oil-tea leaf powder appropriate with 1: 10 Ratio of solid to liquid Add the above viscous colorless liquid and mix thoroughly, then put it in a flask and extract it in an ultrasonic cleaning machine for 5 times, each time for 20 minutes. After filtering out the filter residue, the filtrate extract was centrifuged at 10000r / min for 40min, then filtered, and the filtrate was dried and stored to determine the extraction rate of flavonoids in tea leaf powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com