Method for producing oxymethylene copolymer resin composition, and oxymethylene copolymer resin composition

A technology of oxymethylene copolymer and methylene copolymer, which is applied in the field of oxymethylene copolymer resin composition, can solve problems such as viscosity reduction, and achieve the effect of reducing the amount of formaldehyde produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~18

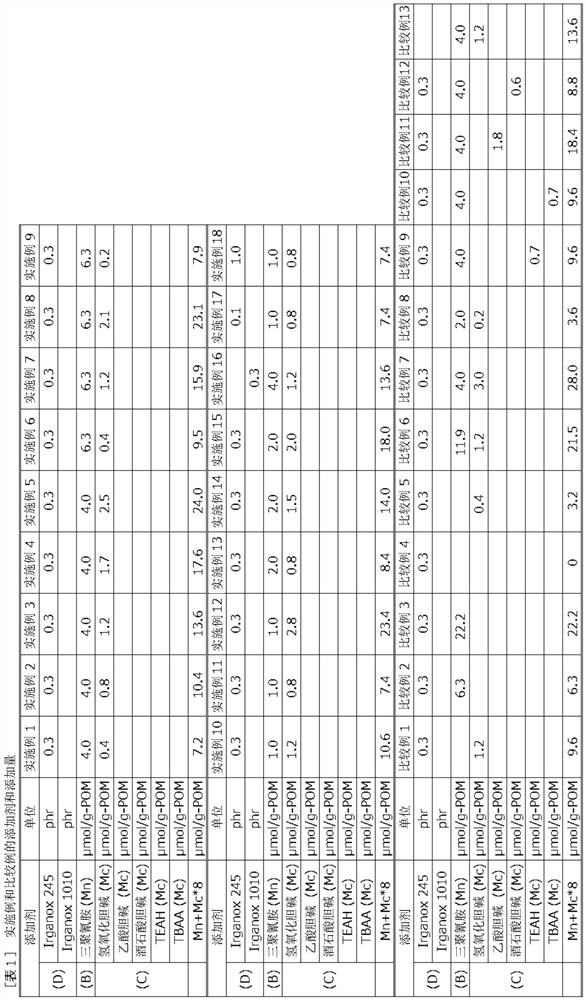

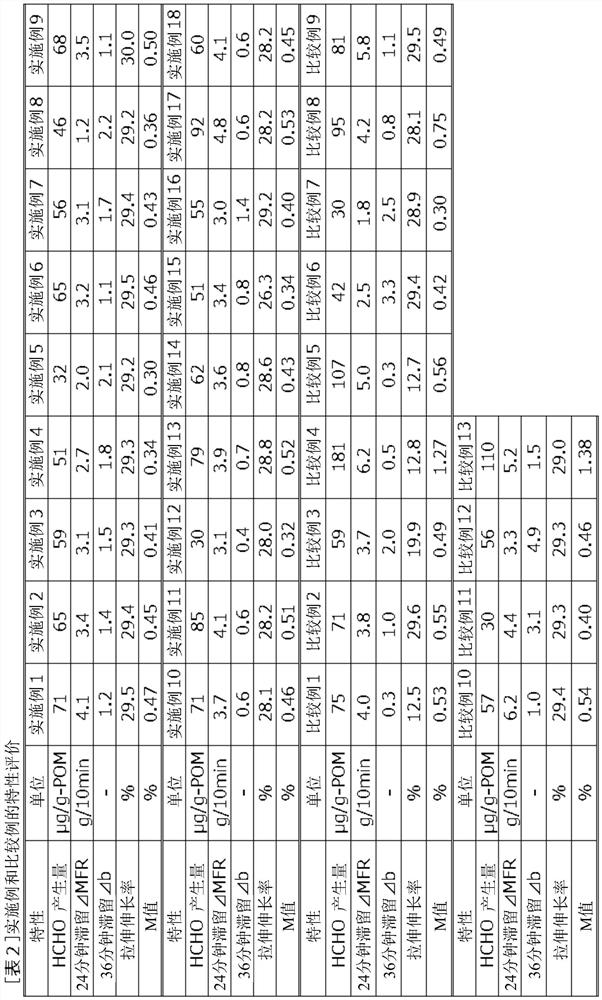

[0085] In Example 1 of the present invention, melamine 4.0 (μmol / g-POM) and choline hydroxide (C) 0.4 ( μmol / g-POM), and triethylene glycol-bis[3-(3-tert-butyl-5-methyl-4-hydroxyphenyl)propionate] as an antioxidant (D) per 100 wt. 0.3 parts by weight of the oxymethylene copolymer (A) was added, and pre-mixed using an FM mixer (Henschel mixer) (manufactured by NIPPON COKE & ENGINEERING COMPANY, LIMITED). Then, using a co-rotating twin-screw extruder (inner diameter 30mm, L / D=25), the mixture was continuously extruded while degassing at a cylinder temperature of 240°C and a reduced pressure of 21.3kPa to obtain oxygen Pellets of methylene copolymer resin composition.

[0086] Regarding Examples 2 to 15, 17 and 18 of the present invention, according to the amounts recorded in Table 1, the addition amounts of melamine (B), choline hydroxide (C) and antioxidant (D) were changed, and the same as in Example 1 The method, condition, obtain the pellet of oxymethylene copolymer resin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com