IWR/CDO co-crystallized zeolite molecular sieve synthesis method

A zeolite molecular sieve and co-crystallization technology, applied in molecular sieve and alkali exchange compounds, chemical instruments and methods, inorganic chemistry and other directions, to achieve the effects of strong operability, low price and wide synthesis range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Dissolve 2.1g of germanium oxide in 10.8g of 45wt% choline hydroxide aqueous solution, add 18.7g of tetraethylorthosilicate (TEOS) and 0.41g of aluminum isopropoxide, after the hydrolysis is complete, stir the container open overnight to volatilize ethanol , propanol and part of water until the reaction mixture reaches the final molar composition.

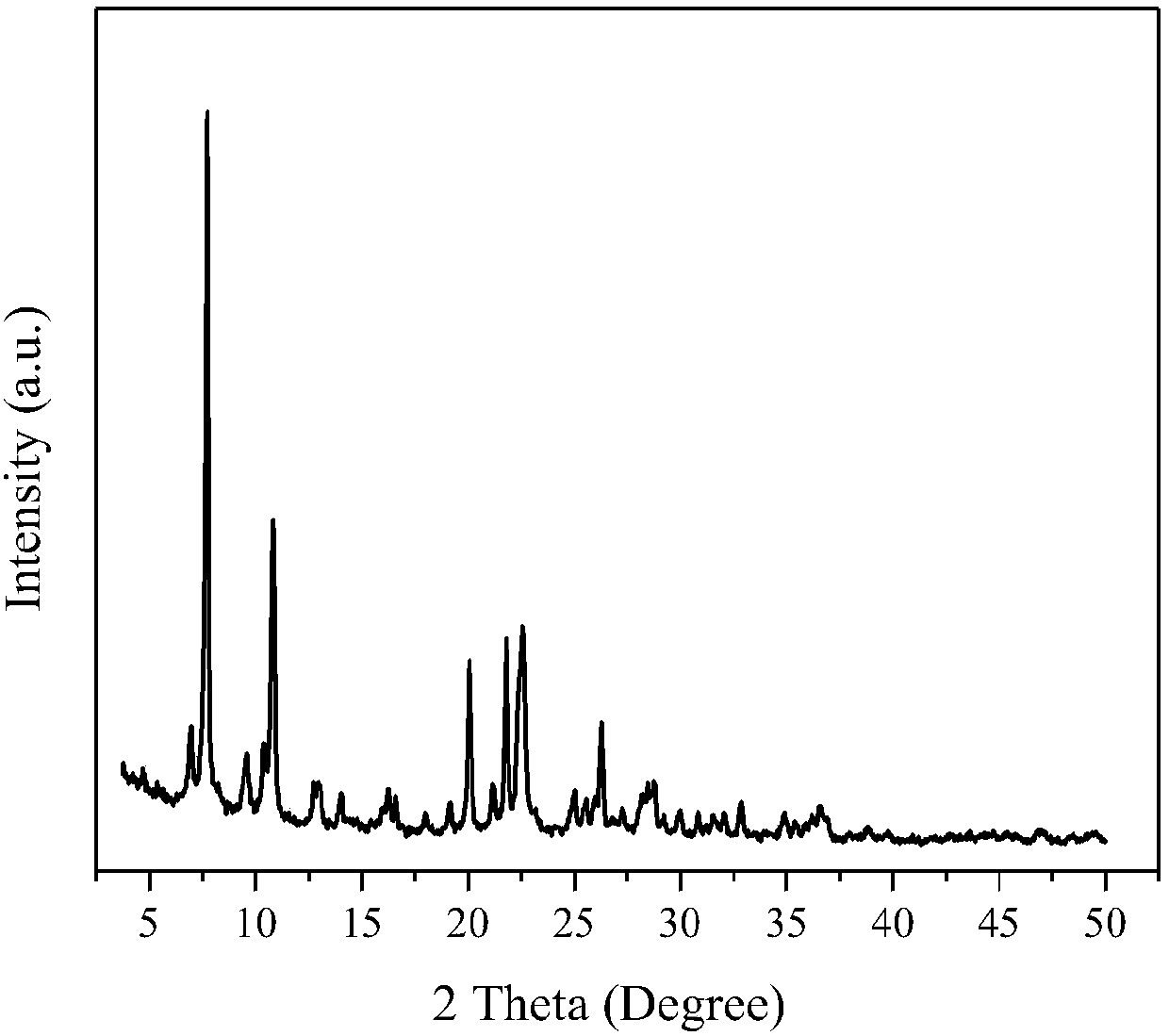

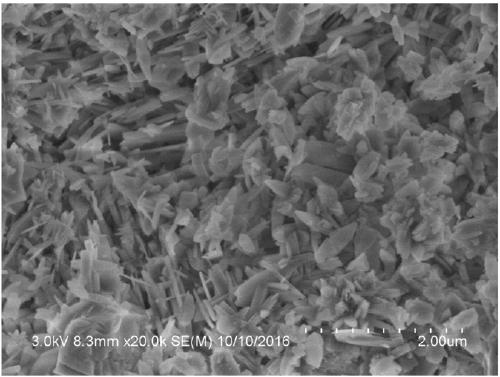

[0020] The above mixture was put into a crystallization kettle with a polytetrafluoroethylene liner, and placed in an oven at 150°C for crystallization for 168 hours. After the reaction, the solid obtained by filtering, washing, drying and calcining is IWR / CDO co-crystal molecular sieve, wherein the proportion of IWR molecular sieve is 65%. The XRD pattern of the sample is as figure 1 As shown, the scanning electron microscope pictures are shown as figure 2 shown.

Embodiment 2

[0022] Dissolve 5.2g of germanium oxide in 13.5g of 45wt% choline hydroxide aqueous solution, add 20.8g of tetraethylorthosilicate (TEOS), after the hydrolysis is complete, open the container and stir overnight to volatilize ethanol and part of the water until the reaction mixture to reach the final molar composition.

[0023] The above mixture was put into a crystallization kettle with a polytetrafluoroethylene liner, and placed in an oven at 170° C. for 72 hours for crystallization. The solid obtained after the reaction is filtered, washed, dried and calcined is an IWR / CDO co-crystal molecular sieve, wherein the proportion of the IWR molecular sieve is 5%.

Embodiment 3

[0025] Dissolve 5.2g germanium oxide in 13.5g 45wt% choline hydroxide aqueous solution, add 20.8g tetraethyl orthosilicate (TEOS) and 0.6g HBeta molecular sieve (SiO 2 / Al 2 o 3 =25), after the hydrolysis was complete, the container was opened and stirred overnight to volatilize ethanol and part of the water until the reaction mixture reached the final molar composition.

[0026] The above mixture was put into a crystallization kettle with a polytetrafluoroethylene liner, and placed in an oven at 160°C for crystallization for 120 hours. After the reaction, the solid obtained by filtering, washing with distilled water, drying and calcining is IWR / CDO co-crystal molecular sieve, wherein the proportion of IWR molecular sieve is 77%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com