A method for pretreatment of crop straw degradation

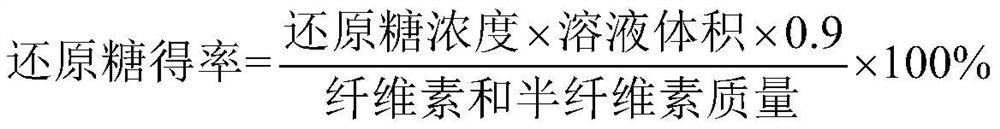

A crop straw and pretreatment technology, which is applied in the field of waste resource utilization, can solve the problems of affecting environmental safety, destroying straw lignin, and poor enzymatic hydrolysis effect, and achieves the effect of simple operation steps and improved reducing sugar yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In the ion-exchange membrane electrolyzer, a homogeneous anion-exchange membrane and a homogeneous cation-exchange membrane are used to divide the ion-exchange membrane electrolyzer into three parts: the cathode area, the salt addition area and the anode area according to the volume ratio of 5:1:5. The anode uses titanium-based platinum Iridium oxide alloy electrode, the cathode uses a titanium plate electrode, the distance between the cathode plate and the anode plate is 4cm, and the effective area of the electrode is 1dm 2 . Add 100mL NaCl solution with a concentration of 5g / L in the middle salt adding area as electrolyte, and add 500mL deionized water in the anode area and cathode area respectively. During electrolysis, at a current density of 4A dm -2After electrolysis for 60 minutes, acidic oxidized electrolyzed water is obtained in the anode area, and alkaline reduced electrolyzed water is obtained in the cathode area. After testing, the pH value of the acidic...

Embodiment 2

[0040] In the ion-exchange membrane electrolyzer, a homogeneous anion-exchange membrane and a homogeneous cation-exchange membrane are used to divide the ion-exchange membrane electrolyzer into three parts: the cathode area, the salt addition area and the anode area according to the volume ratio of 5:1:5. The anode uses titanium-based platinum Iridium oxide alloy electrode, the cathode uses a titanium plate electrode, the distance between the cathode plate and the anode plate is 4cm, and the effective area of the electrode is 1dm 2 . Add 100mL NaCl solution with a concentration of 5g / L in the middle salt adding area as electrolyte, and add 500mL deionized water in the anode area and cathode area respectively. During electrolysis, at a current density of 4A·dm -2 After electrolysis for 60 minutes, acidic oxidized electrolyzed water is obtained in the anode area, and alkaline reduced electrolyzed water is obtained in the cathode area. After testing, the pH value of the acidi...

Embodiment 3

[0042] In the ion-exchange membrane electrolyzer, a homogeneous anion-exchange membrane and a homogeneous cation-exchange membrane are used to divide the ion-exchange membrane electrolyzer into three parts: the cathode area, the salt addition area and the anode area according to the volume ratio of 5:1:5. The anode uses titanium-based platinum Iridium oxide alloy electrode, the cathode uses a titanium plate electrode, the distance between the cathode plate and the anode plate is 4cm, and the effective area of the electrode is 1dm 2 . Add 100mL NaCl solution with a concentration of 4g / L in the middle salt adding area as electrolyte, and add 500mL deionized water in the anode area and cathode area respectively. During electrolysis, at a current density of 3A dm -2 After electrolysis for 60 minutes, acidic oxidized electrolyzed water is obtained in the anode area, and alkaline reduced electrolyzed water is obtained in the cathode area. After testing, the pH value of the acidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com