High-tolerance environment-friendly microbial modifier as well as preparation method and application thereof

A technology of tolerance and microorganisms, applied in the field of crack repair, can solve the problems of only wide and shallow cracks, limited application, and reduced urea hydrolysis rate, so as to achieve enhanced reinforcement or repair effects, avoid bacterial peeling, shorten The effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

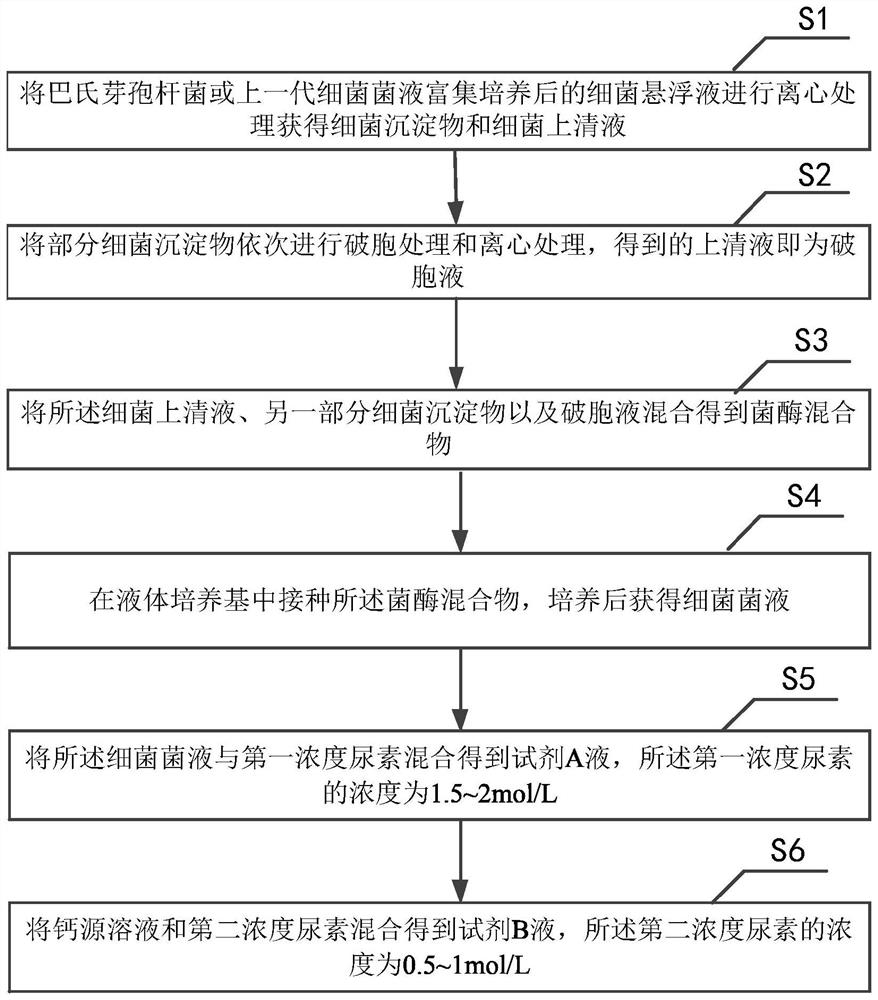

[0028] see figure 1 , the present invention provides a kind of preparation method of the environment-friendly microorganism modifying agent of high tolerance, and this environment-friendly microorganism modifying agent of high tolerance comprises reagent A liquid and reagent B liquid, and described reagent A is centrifuged and purified, A mixed solution of enriched and cultured bacterial solution and a high-concentration urea solution, the reagent B is a mixed solution of nutrients required for bacterial metabolism, a high-concentration calcium source solution, and a low-concentration urea solution. The preparation method of the environment-friendly microbial modifier comprises the following S1-S6.

[0029] S1: Centrifuge the bacterial suspension after enrichment and culture of Bacillus pasteurianus or the previous generation of bacterial liquid to obtain bacterial sediment and bacterial supernatant.

[0030] The Bacillus pasteurianus in this example originated from the Ameri...

Embodiment 1

[0061] Step 1: Mix the bacterial liquid after centrifugal purification and enrichment culture treatment with the 2mol / L first concentration urea solution according to the volume ratio of 1:1, and cultivate for 24 hours at an ambient temperature of 30°C and an oscillation speed of 160rpm. Obtain reagent A solution.

[0062] Step 2: the calcium chloride solution with a concentration of 2mol / L and the second concentration urea solution with a concentration of 0.5mol / L are mixed according to a volume ratio of 1:1, and the initial pH of the mixed solution is adjusted to 6.0 using dilute hydrochloric acid to obtain Reagent B solution.

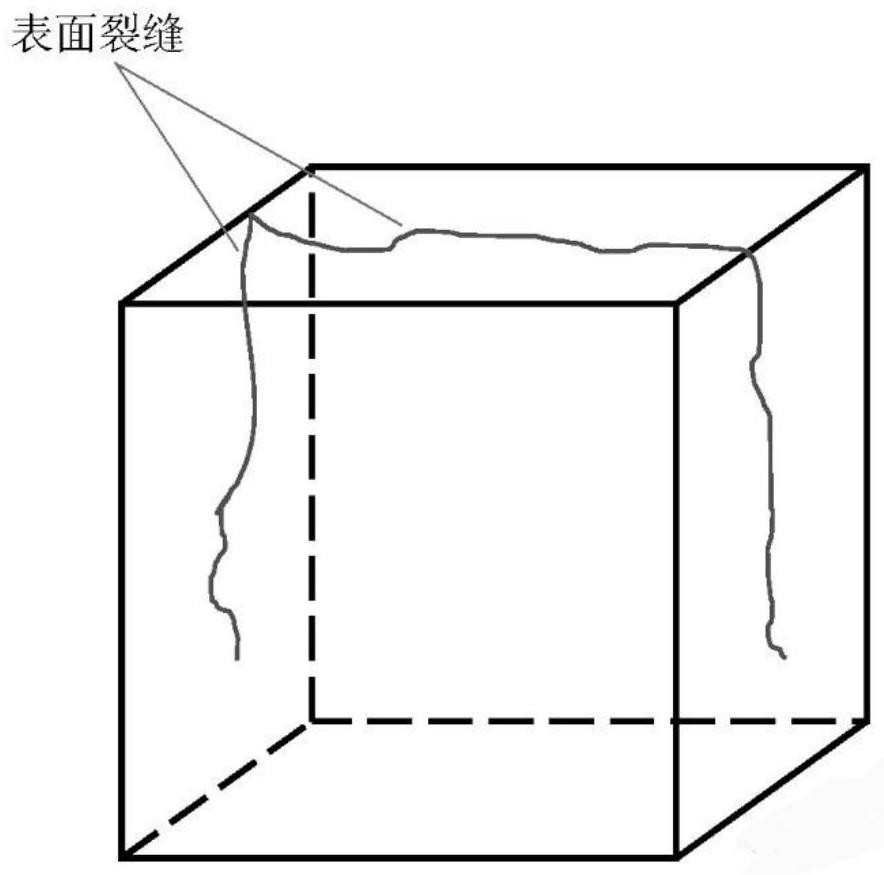

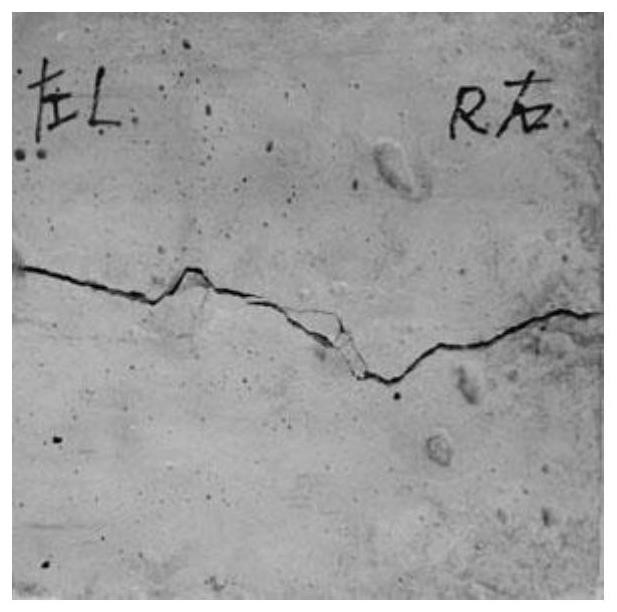

[0063] In this embodiment, the prepared microbial modifier is applied to figure 2 The concrete test block shown was used to test the formation of calcium carbonate crystals on the crack surface after using the microbial modifier to repair deep cracks. The specific steps of the test are as follows:

[0064] Step 1: Plug the cracks: use sandpaper t...

Embodiment 2

[0070] Step 1: Mix the bacterial liquid after centrifugal purification and enrichment culture treatment with 1.5mol / L first concentration urea solution according to the volume ratio of 1:1, and cultivate for 24 hours under the conditions of ambient temperature 30°C and shaking speed 160rpm , to obtain reagent A solution.

[0071] Step 2: mixing the calcium chloride solution with a concentration of 1.5 mol / L and the second concentration urea solution with a concentration of 1 mol / L at a volume ratio of 1:1, and using dilute hydrochloric acid to adjust the initial pH of the mixed solution to 6.0 to obtain Reagent B solution.

[0072] Using the corresponding application method in Example 1, the calcium carbonate coverage area of the cracked surface of the repaired concrete block is 63% of the cracked surface area, and it is roughly in a uniform adhesion mode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com