Method for preparing composite material from waste banknote paper, secret-related waste paper and waste plastics

A composite material and banknote paper technology is applied in the field of resource utilization and recycling of waste printing materials. Utilize the effect of efficient, thorough and efficient resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

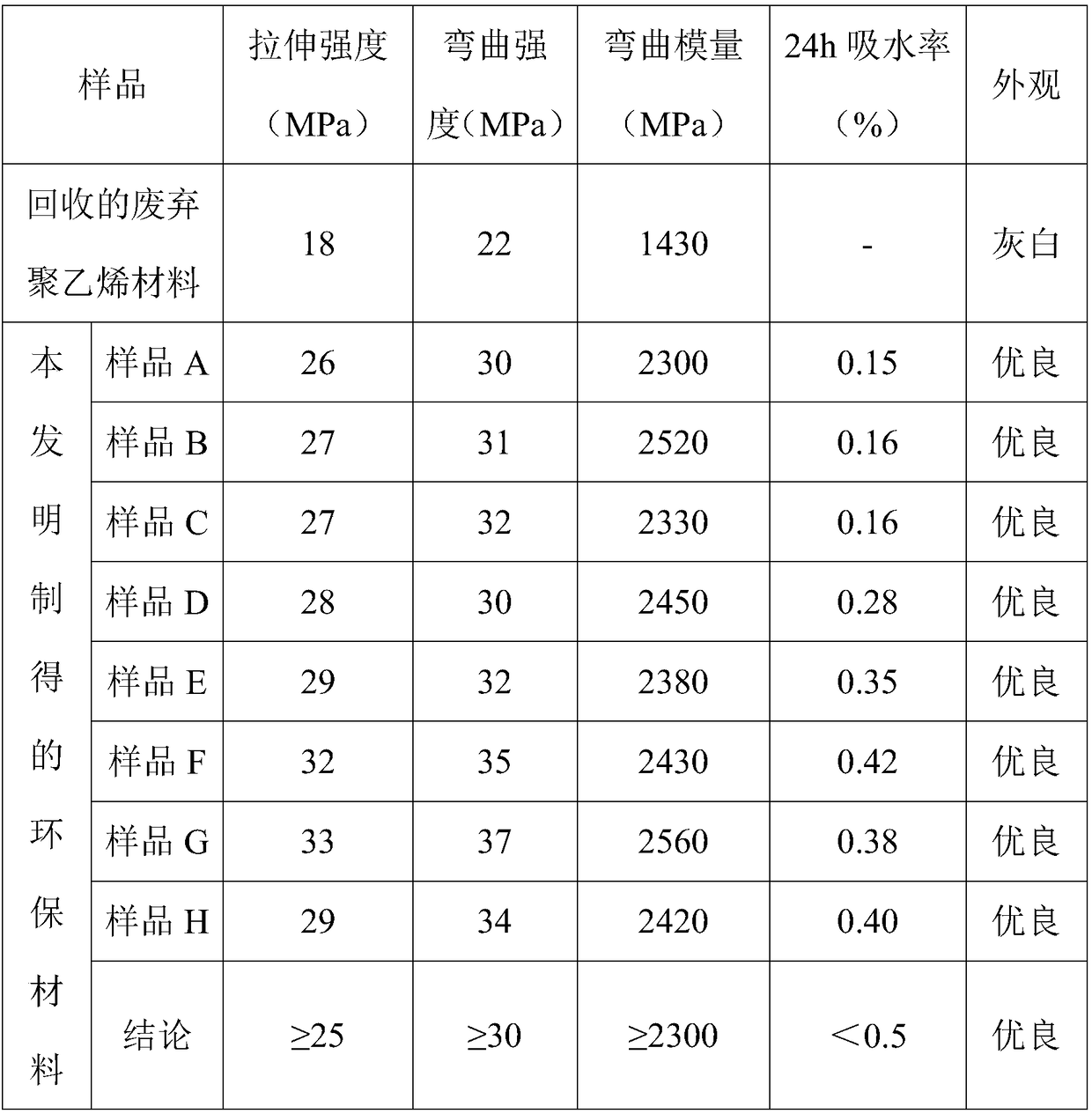

Examples

Embodiment 1

[0039] Step 1. Pretreat banknotes and secret-related waste paper provided by bank departments, banknote printing factories or related departments, optimize the fiber structure and shape of waste banknotes and secret-related waste paper, and obtain pre-modified fibers;

[0040] Step 1.1 Shred waste banknotes and secret-related waste paper. First, coarsely crush paper pieces of about 2cm×2cm, and then continue to use a universal shredder to crush the waste paper pieces into fibers, and control the fiber length of the waste paper paper to about 3-5mm. The fiber aspect ratio is about 10-20, and the fine fiber content is less than 15%;

[0041] Step 1.2 Weigh in turn 100 parts of waste paper fibers obtained in step 1.1, 3 parts of monoalkoxy titanate coupling agent and 20 parts of absolute ethanol, pour the weighed absolute ethanol into a beaker, and then add monoalkoxy titanate coupling agent base titanate coupling agent, stir evenly to obtain a mixed modified liquid, and put the ...

Embodiment 2

[0047] Step 1. Pretreat banknotes and secret-related waste paper provided by bank departments, banknote printing factories or related departments, optimize the fiber structure and shape of waste banknotes and secret-related waste paper, and obtain pre-modified fibers;

[0048] Step 1.1 Shred waste banknotes and secret-related waste paper. First, coarsely crush paper pieces of about 2cm×2cm, and then continue to use a universal shredder to crush the waste paper pieces into fibers, and control the fiber length of the waste paper paper to about 3-5mm. The fiber aspect ratio is about 10-20, and the fine fiber content is less than 15%;

[0049] Step 1.2 Weigh in turn 100 parts of waste paper fiber obtained in step 1.1, 4 parts of monoalkoxy titanate coupling agent and 20 parts of absolute ethanol, pour the weighed absolute ethanol into a beaker, and then add monoalkoxy titanate coupling agent base titanate coupling agent, stir evenly to obtain a mixed modified liquid, and put the m...

Embodiment 3

[0055] Step 1. Pretreat banknotes and secret-related waste paper provided by bank departments, banknote printing factories or related departments, optimize the fiber structure and shape of waste banknotes and secret-related waste paper, and obtain pre-modified fibers;

[0056] Step 1.1 Shred waste banknotes and secret-related waste paper. First, coarsely crush paper pieces of about 2cm×2cm, and then continue to use a universal shredder to crush the waste paper pieces into fibers, and control the fiber length of the waste paper paper to about 3-5mm. The fiber aspect ratio is about 10-20, and the fine fiber content is less than 15%;

[0057] Step 1.2 Weigh 100 parts of waste paper fibers obtained in step 1.1, 5 parts of monoalkoxypyrophosphate titanate coupling agent and 20 parts of absolute ethanol in turn, pour the weighed absolute ethanol into a beaker, and then Add a monoalkoxypyrophosphate titanate coupling agent, stir evenly to obtain a mixed modified liquid, and put the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com