A kind of thin-film solar cell and its manufacturing method

A technology for solar cells and thin-film cells, applied in the field of solar cells, can solve the problems of incompatibility of coating equipment, increase equipment cost, increase substrate cost, etc., and achieve the effects of simple structure, convenient production, and less material restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

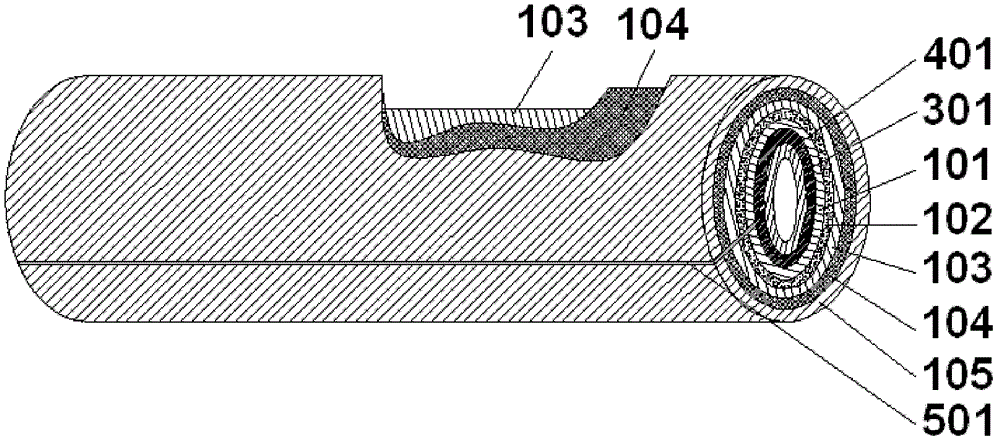

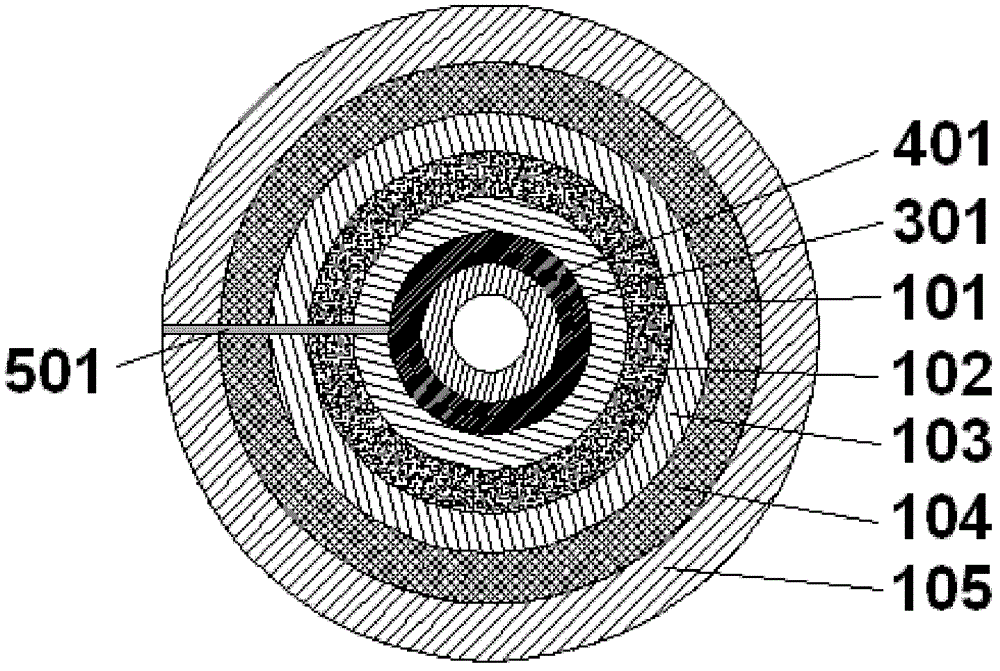

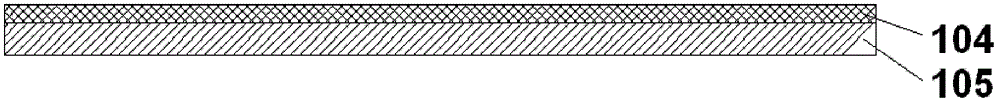

[0050] See figure 1 and figure 2 , this embodiment is a specific implementation of the first solution of the present invention, a cylindrical substrate is used to manufacture a cylindrical thin-film solar cell, and the specific structure includes a lining core 401, a thin-film battery layer and a The packaging material 301 between the lining core 401 and the thin film battery layer and encapsulating the thin film battery layer on the lining core 401; the thin film battery layer includes a protective layer 101, a back electrode layer 102, a power generation layer 103, The transparent conductive layer 104 and the transparent flexible substrate 105; the encapsulation material 301 is set on the outside of the core 401, both of which are cylindrical in shape; the back electrode layer 102, the power generation layer 103 and the transparent conductive layer 104 are respectively scattered and etched with the first Three insulating slots 203 , a second insulating slot 202 and a first...

Embodiment 2

[0063] See Figure 11 , this embodiment is a specific implementation of the second scheme of the present invention. What is still used is a cylindrical substrate to manufacture a cylindrical thin-film solar cell, including the lining core 401, the thin-film battery layer and the The packaging material 301 between the lining core 401 and the thin-film battery layer and encapsulating the thin-film battery layer on the lining core 401; the thin-film battery layer includes a flexible substrate 105, a back electrode layer 102, and a power generation layer 103 that are sequentially covered from the inside to the outside. , a transparent conductive layer 104 and a protective layer 101; the encapsulation material and the lining core 401 are non-flat three-dimensional structures with the same shape; the back electrode layer 102, the power generation layer 103 and the transparent conductive layer 104 are respectively etched with first insulating grooves 201, The second insulating groove...

Embodiment 3

[0076] See Figure 12 , this embodiment is another specific implementation of the second solution of the present invention. On the basis of Embodiment 2, it also includes a transparent protective cover 601 outside the protective layer 101. The shape of the protective cover 601 can be the same as that of the lining core 401. Consistent, so that better light transmission effect can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com