A kind of method of high-yield benzene of C6 alkane

A technology for alkanes and n-hexane, applied in chemical instruments and methods, purification/separation of hydrocarbons, carbon compound catalysts, etc., can solve problems such as unsatisfactory, difficult aromatization, low selectivity, etc., to avoid production coke effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

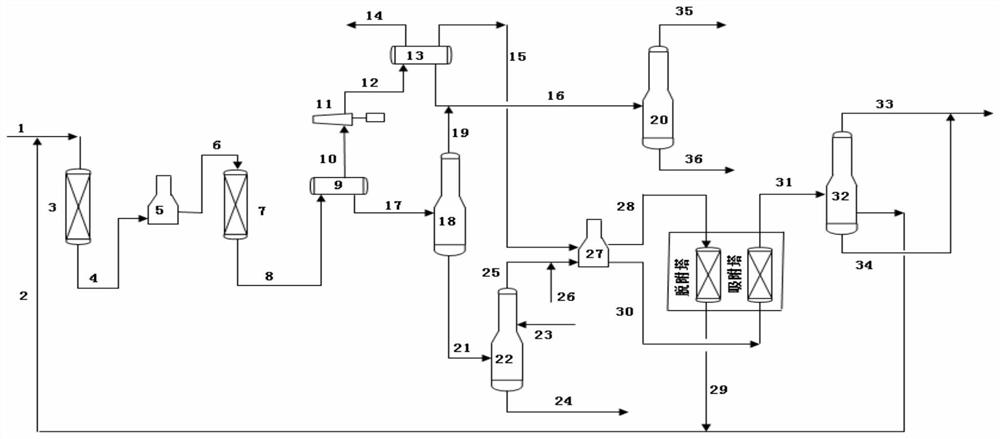

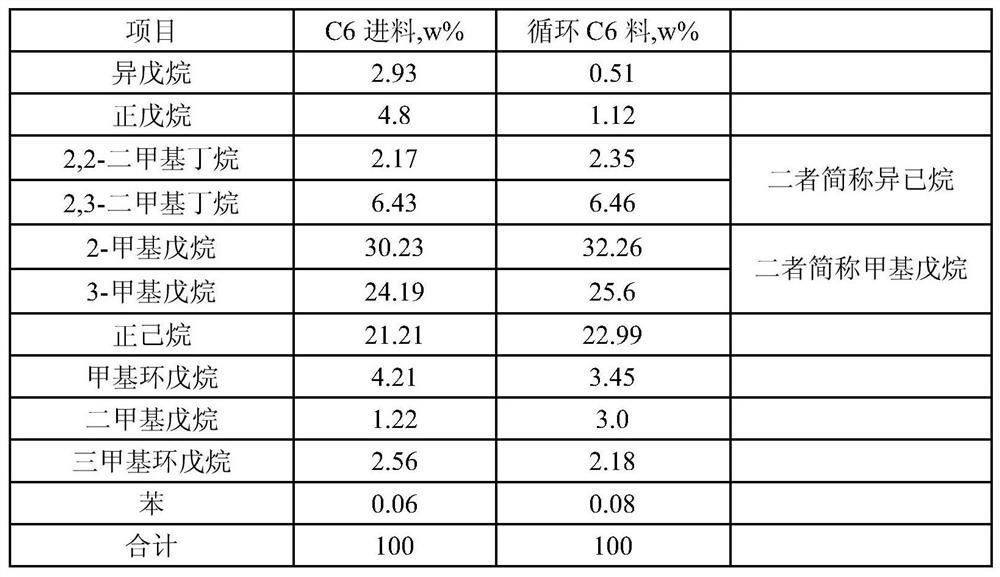

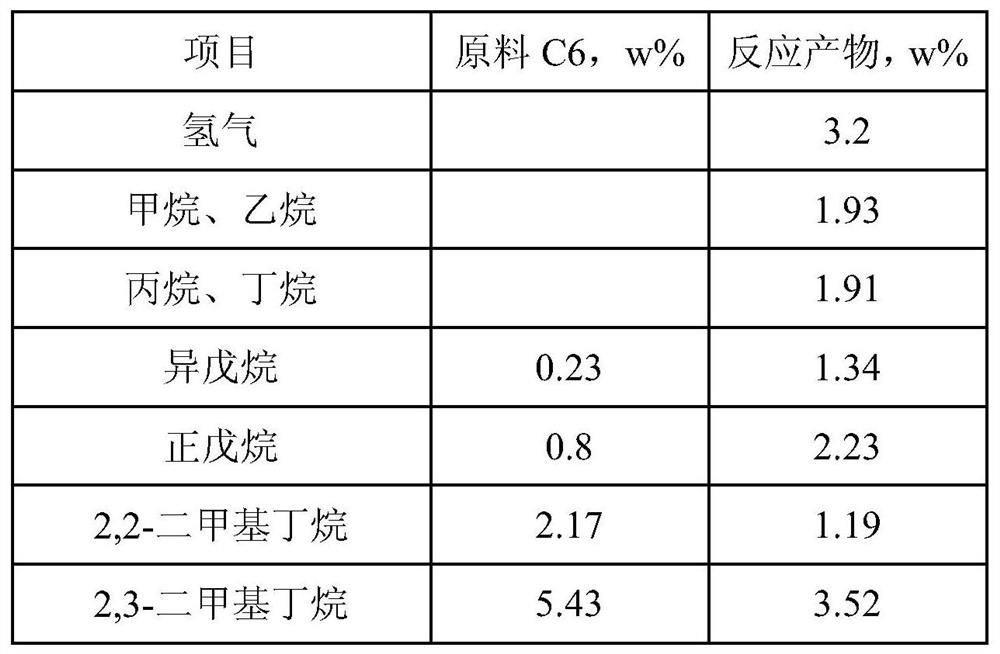

[0055] In this embodiment, the attached figure 1 In all the shown process flow, the C6 raw material is introduced into the above-mentioned reaction and separation system. The composition of alkane C6 feedstock and reaction product is shown in Table 2 below. Reaction conditions for producing more benzene: reaction temperature 480°C, pressure 0.35MPa(g), hydrogen-oil volume ratio 600:1, raw material volume space velocity 2.5h -1. At this time, the conversion rate of methylpentane is about 47.34%, the conversion rate of n-hexane is about 58.78%, and the yield of benzene reaches 41%.

[0056] According to the process of the present invention, the reaction product is separated and the material after benzene is extracted and mixed with fresh C6 feed into the 5A molecular sieve adsorption system and the feed composition of the deisohexane tower after desorbing n-hexane is shown in Table 3. At this time, the adsorption temperature of the 5A molecular sieve system is 290°C, the adso...

Embodiment 2

[0068] In this embodiment, the attached figure 1 For all the shown process flow, the C6 raw material is introduced into the above-mentioned reaction separation system. The composition of alkane C6 feedstock and reaction product is shown in Table 6 below. Reaction conditions for prolific benzene: reaction temperature 490°C, pressure 0.40MPa(g), hydrogen to oil volume ratio 600:1, raw material volume space velocity 2.5h -1 . At this time, the conversion rate of methylpentane is about 48.21%, the conversion rate of n-hexane is about 59.58%, and the yield of benzene reaches 39.67%.

[0069] According to the process of the present invention, the reaction product is separated and the material after benzene is extracted and mixed with fresh C6 feed into the 5A molecular sieve adsorption system and the feed composition of the deisohexane tower after desorbing n-hexane is shown in Table 7. At this time, the adsorption temperature of the 5A molecular sieve system is 300°C, the adsorp...

Embodiment 3

[0080] In this embodiment, the attached figure 1 For all the shown process flow, the C6 raw material is introduced into the above-mentioned reaction separation system. The compositions of alkane C6 feedstock and reaction products are shown in Table 10 below. Reaction conditions for prolific benzene: reaction temperature 500°C, pressure 0.30MPa(g), hydrogen to oil volume ratio 600:1, raw material volume space velocity 2.5h -1 . At this time, the conversion rate of methylpentane is about 47.18%, the conversion rate of n-hexane is about 58.05%, and the yield of benzene reaches 40.67%.

[0081] According to the process of the present invention, the reaction product is separated and the material after benzene is extracted and mixed with fresh C6 feed into the 5A molecular sieve adsorption system and the feed composition of the deisohexane tower after desorbing n-hexane is shown in Table 11. At this time, the adsorption temperature of the 5A molecular sieve system is 310°C, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com