A kind of preparation method of multilayer graphene

A multi-layer graphene and graphite technology, applied in graphene, chemical instruments and methods, nano-carbon, etc., can solve problems such as inability to obtain performance and matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

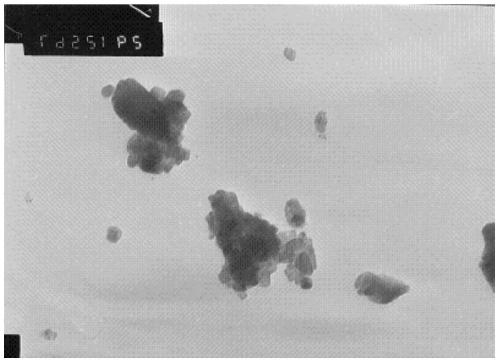

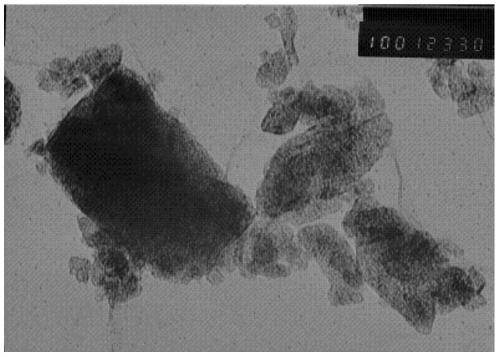

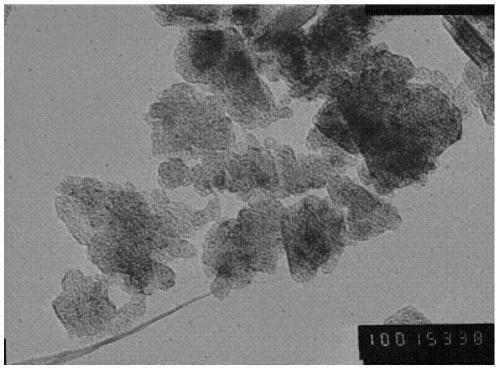

Image

Examples

preparation example Construction

[0037] The preparation method of multilayer graphene of the present invention mainly comprises the steps:

[0038] A. Put the graphite into the ultrasonic device, and use the cavitation effect for ultrasonic treatment;

[0039] B, putting the graphite after the above-mentioned ultrasonic treatment into a high-pressure device for pressurization;

[0040] C. Pumping the above-mentioned pressure-treated graphite into a vacuum tank to dissociate between the (001) crystal planes of the above-mentioned graphite to obtain graphite in flake layers.

[0041] Further, in order to obtain dry multilayer graphene, the graphite treated in step C can be dried.

[0042] In a preferred embodiment of the present invention, step A is to disperse graphite in a liquid, such as water (such as distilled water) or an organic solvent (such as ethanol, acetone, etc.), and then put it into an ultrasonic device, using ultrasonic Cavitation effect, when the sound wave passes through the liquid, the soun...

Embodiment 1

[0053] Adopt natural graphite ore produced in Shandong, select graphite crystals with a graphite crystal size greater than 1 square centimeter, gently break these graphites into graphite flake crystals with a wooden stick, weigh 100 grams, put into a 5000ml flask, and add 5000ml of distilled water. Insert an ultrasonic generator into the mouth of the flask, turn on the power supply, and start ultrasonic treatment. After 15 minutes, take out the ultrasonic generator, pour the material in the bottle into a 5000ml high-pressure reactor, close the reactor, and then reduce the pressure by adding distilled water. Increase to 25Mpa and keep the pressure for 10 minutes. The outlet of the reaction kettle is connected to the feed pipe of the miniature high-pressure diaphragm pump in advance, and the discharge pipe of the diaphragm pump is connected to the vacuum tank. After 10 minutes, the diaphragm pump was started, and the materials in the reactor were pumped into the vacuum tank at h...

Embodiment 2

[0056] Adopt natural graphite ore produced in Shandong, select graphite crystals with a graphite crystal size greater than 1 square centimeter, gently break these graphites into graphite flake crystals with a wooden stick, weigh 100 grams, put into a 5000ml flask, and add 5000ml of distilled water. Insert an ultrasonic generator into the mouth of the flask, turn on the power supply, and start ultrasonic treatment. After 15 minutes, take out the ultrasonic generator, pour the material in the bottle into a 5000ml high-pressure reactor, close the reactor, and then reduce the pressure by adding distilled water. Increase to 25Mpa and keep the pressure for 10 minutes. The outlet of the reaction kettle is connected to the feed pipe of the miniature high-pressure diaphragm pump in advance, and the discharge pipe of the diaphragm pump is connected to the vacuum tank. After 10 minutes, the diaphragm pump was started, and the materials in the reactor were pumped into the vacuum tank at h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com