Wood rolled pencil and making method thereof

A production method and pencil technology, which is applied in the field of stationery, can solve the problems of low wood utilization rate, eccentricity of the pen holder and pencil lead, etc., and achieve the effects of easy pencil sharpening, wood saving and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

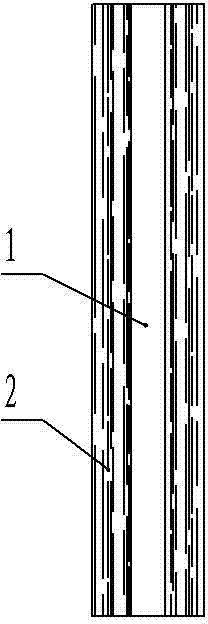

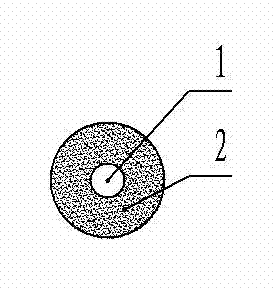

[0023] figure 1 , figure 2 The wooden rolled pencil shown is composed of a pencil lead 1 and a pen holder 2 wrapped around the pencil lead. Axial parallel.

[0024] The manufacture method of this wooden volume pencil is characterized in that: comprising the following steps:

[0025] a. Material selection: choose wood with a diameter of 100MM ~ 150MM;

[0026] b. blanking: cut the timber into a length of 185MM;

[0027] c. Softening: Dilute the wood softener stock solution into a 5%-8% water-soluble emulsion, and soak the wood obtained in step b for 24 hours to 48 hours;

[0028] d. planing: planing the wood obtained in c step into thin slices with a thickness of 0.5MM along the circumferential direction with a planer;

[0029] e. Drying: drying the thin slices at a drying temperature of 60°C to 70°C until the moisture content is 8% to 12%;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com