Patents

Literature

73results about How to "Easy to sharpen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

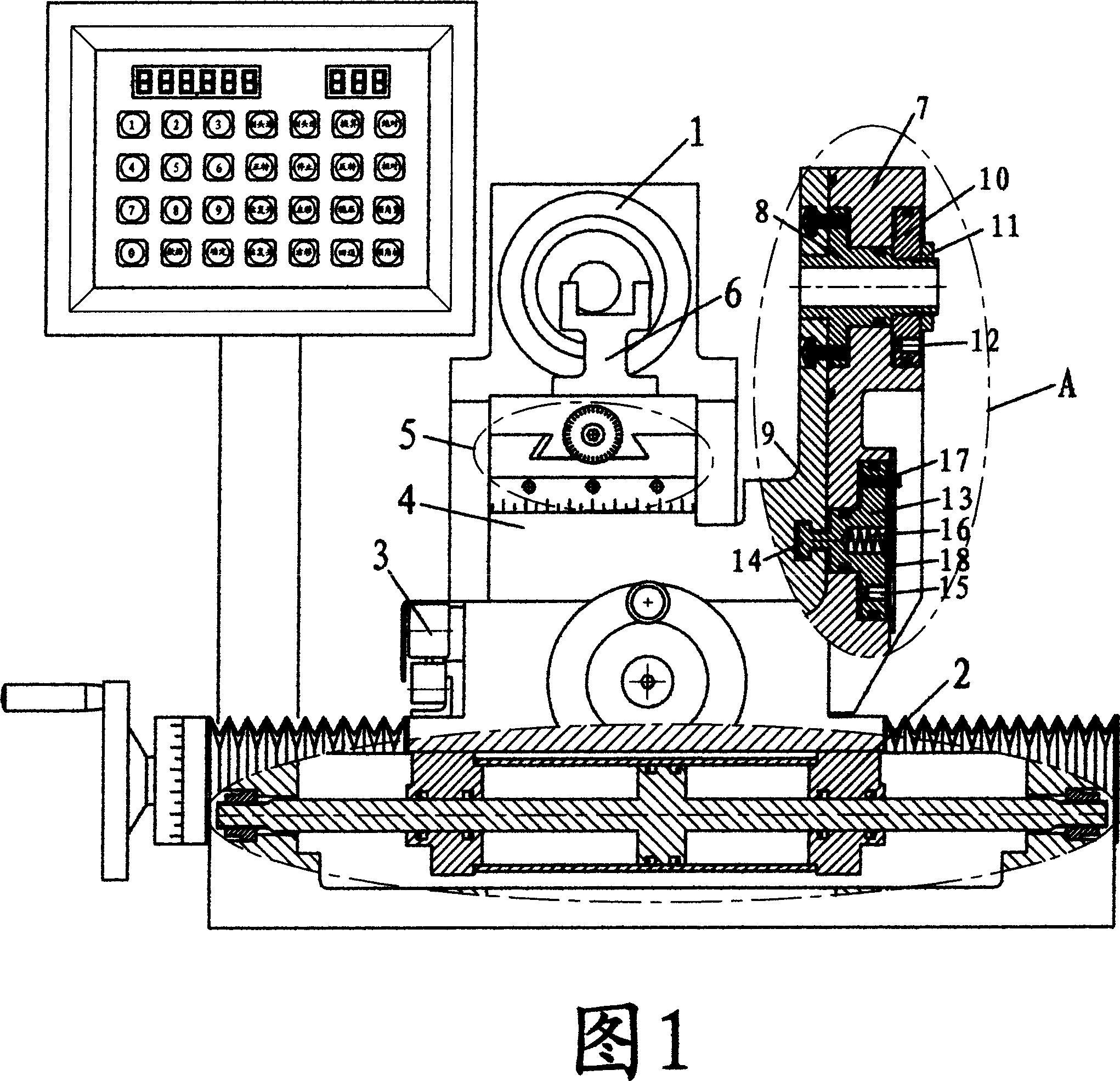

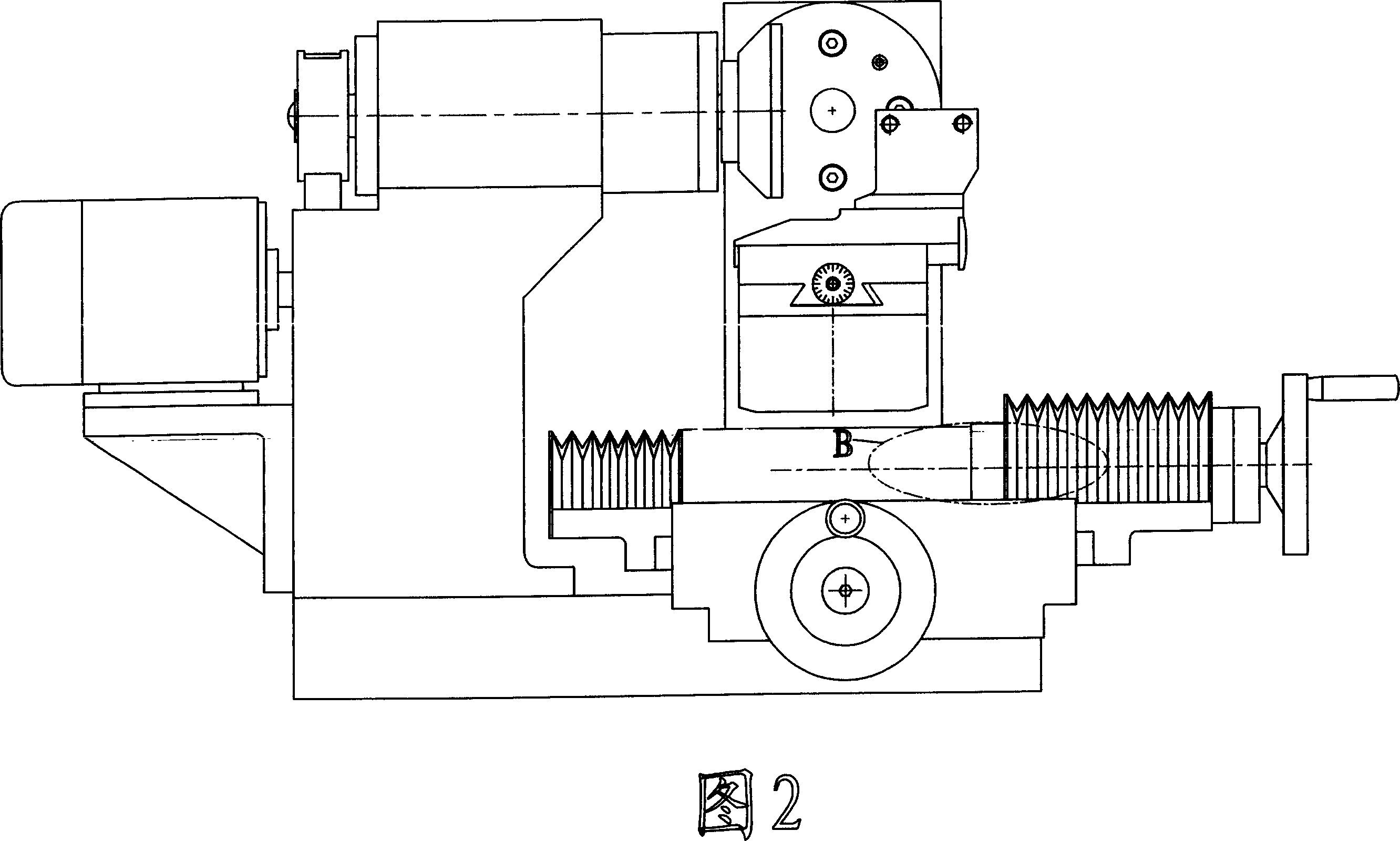

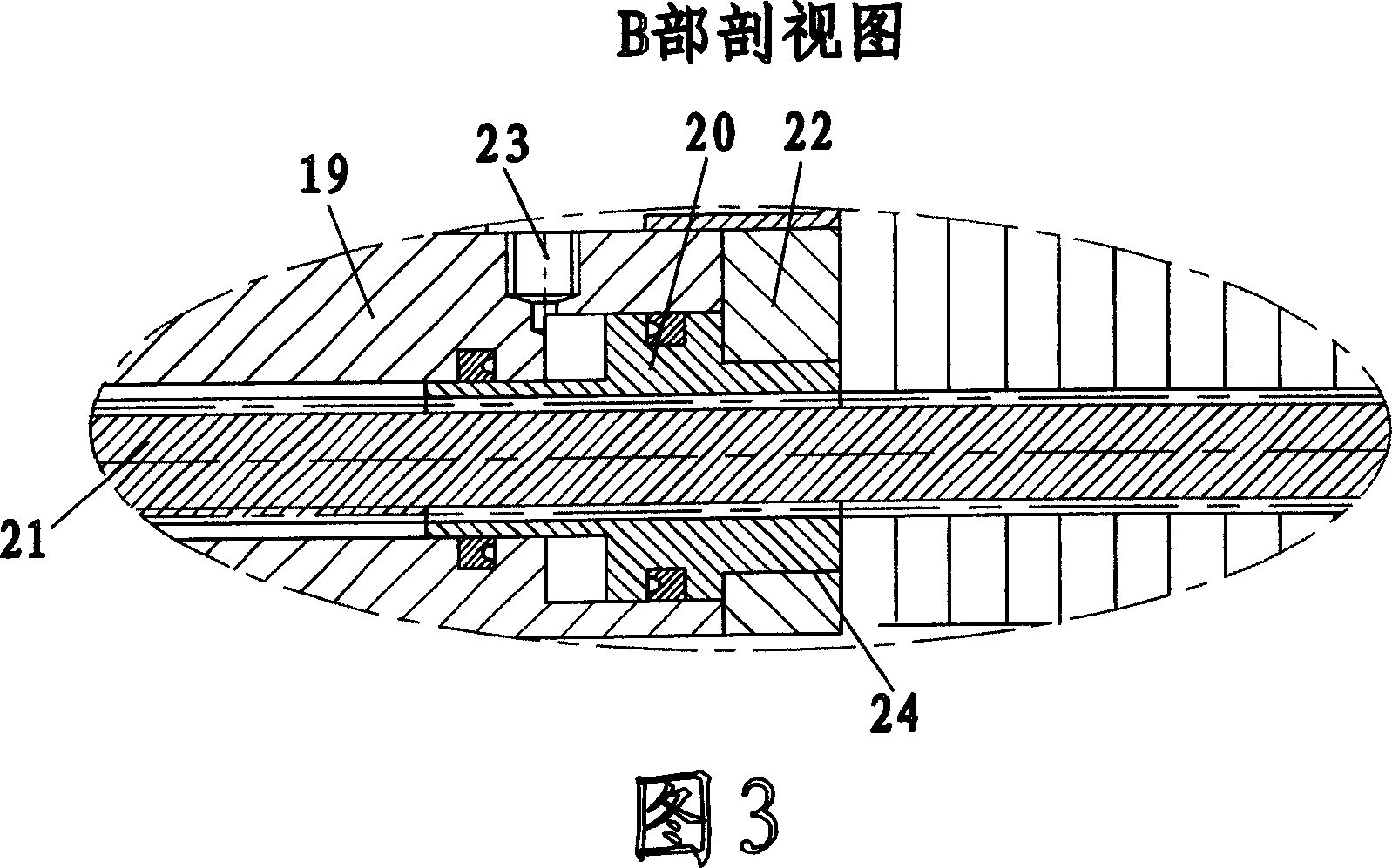

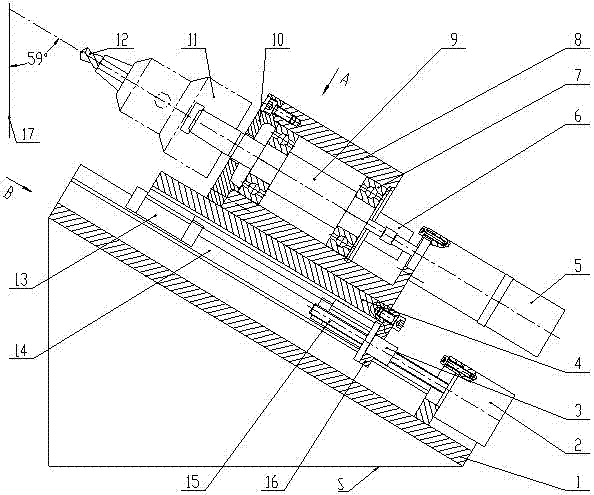

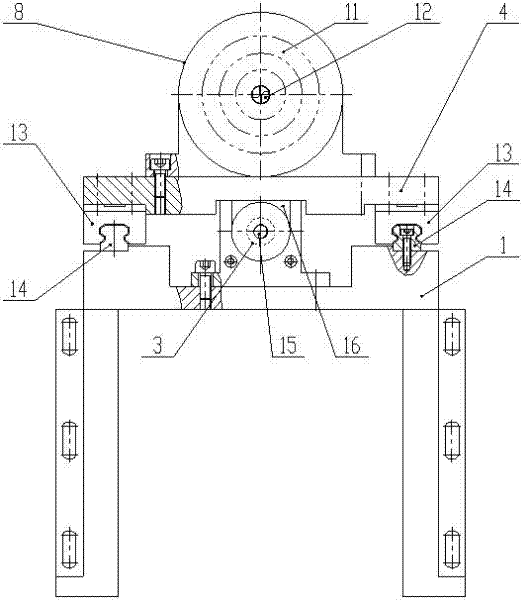

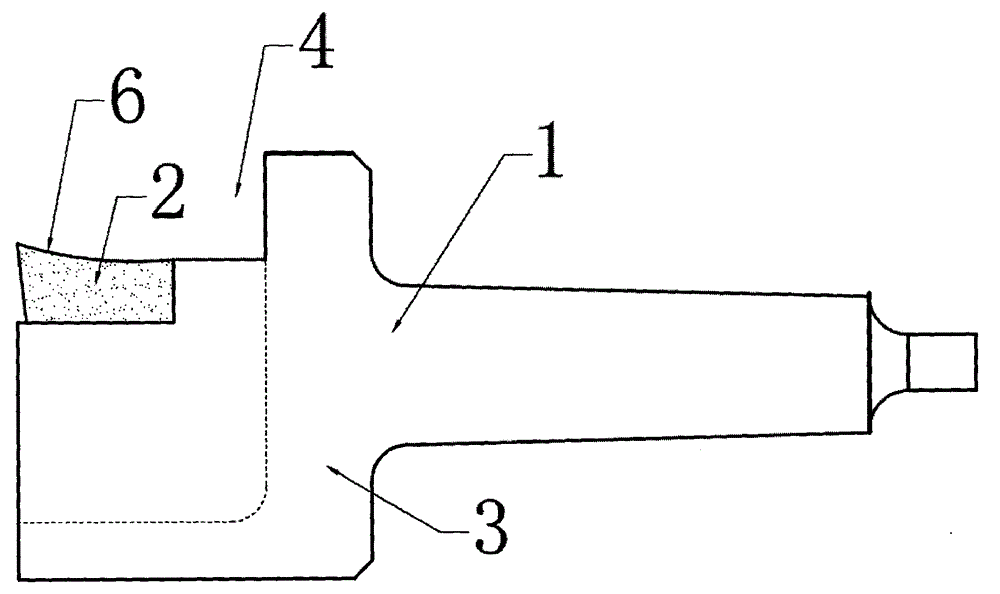

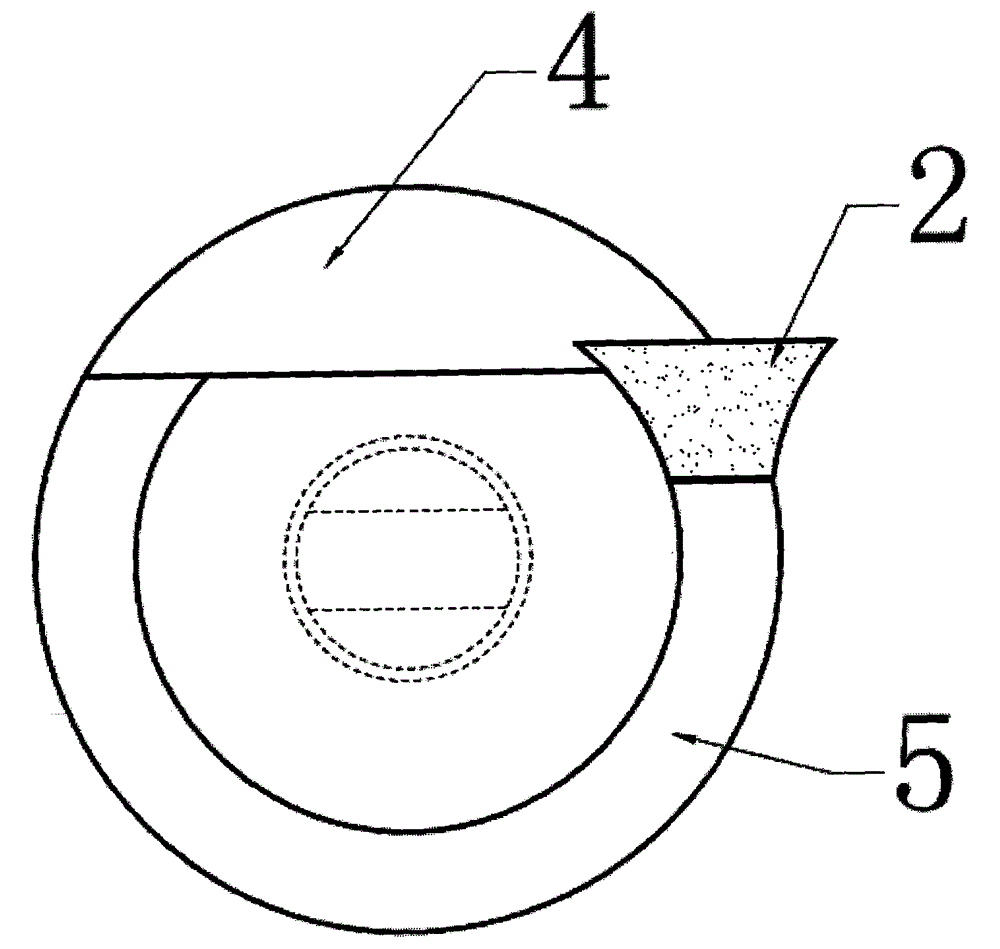

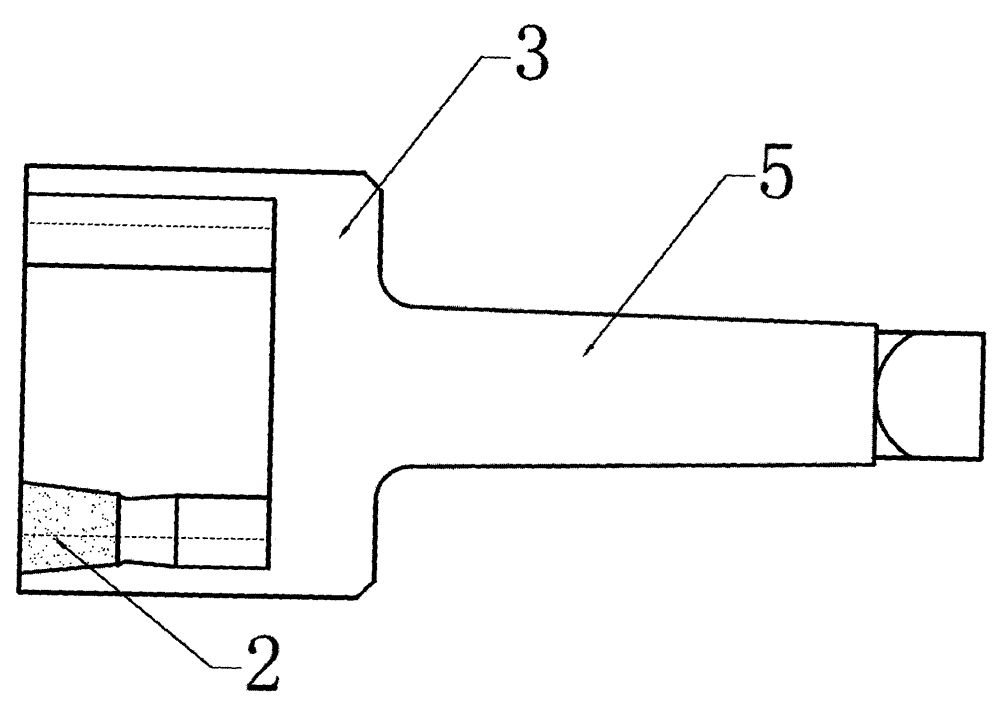

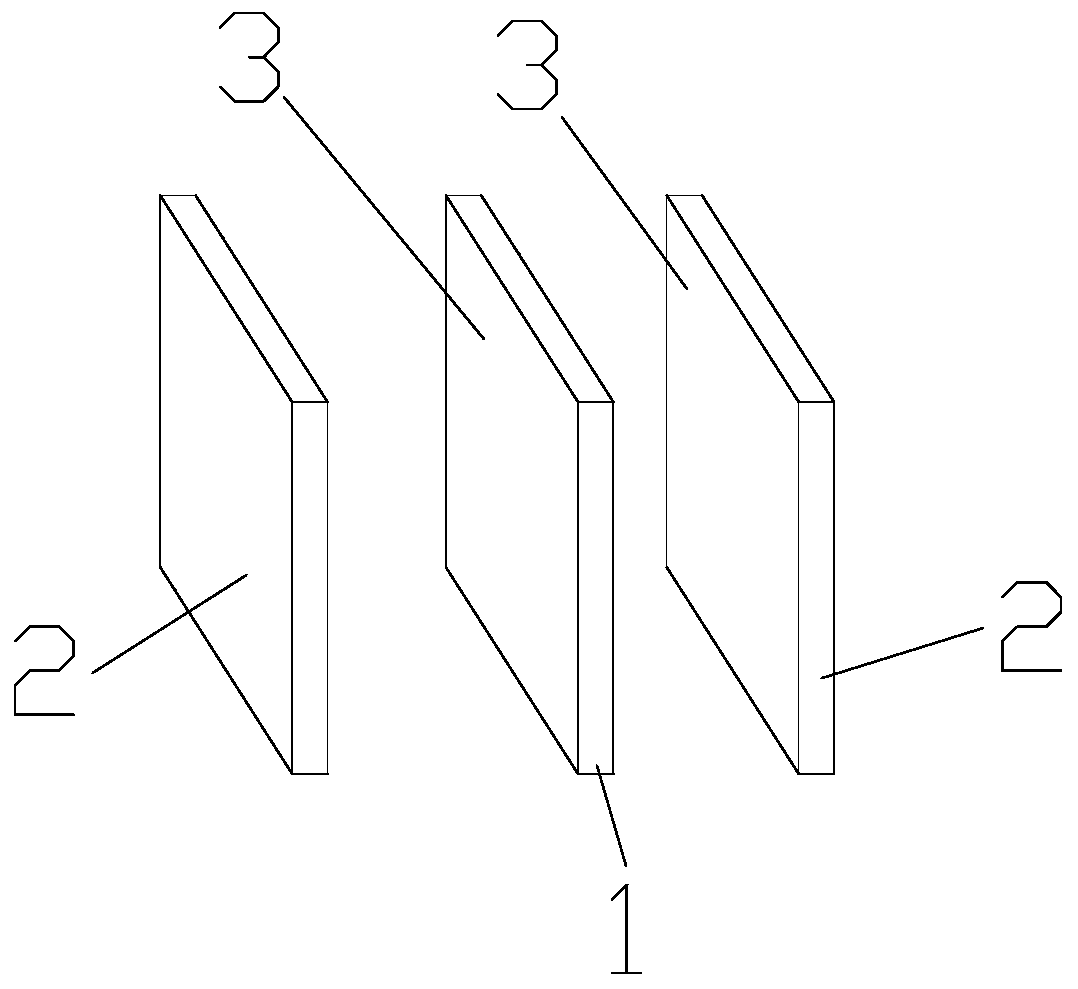

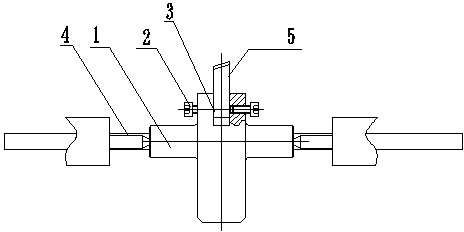

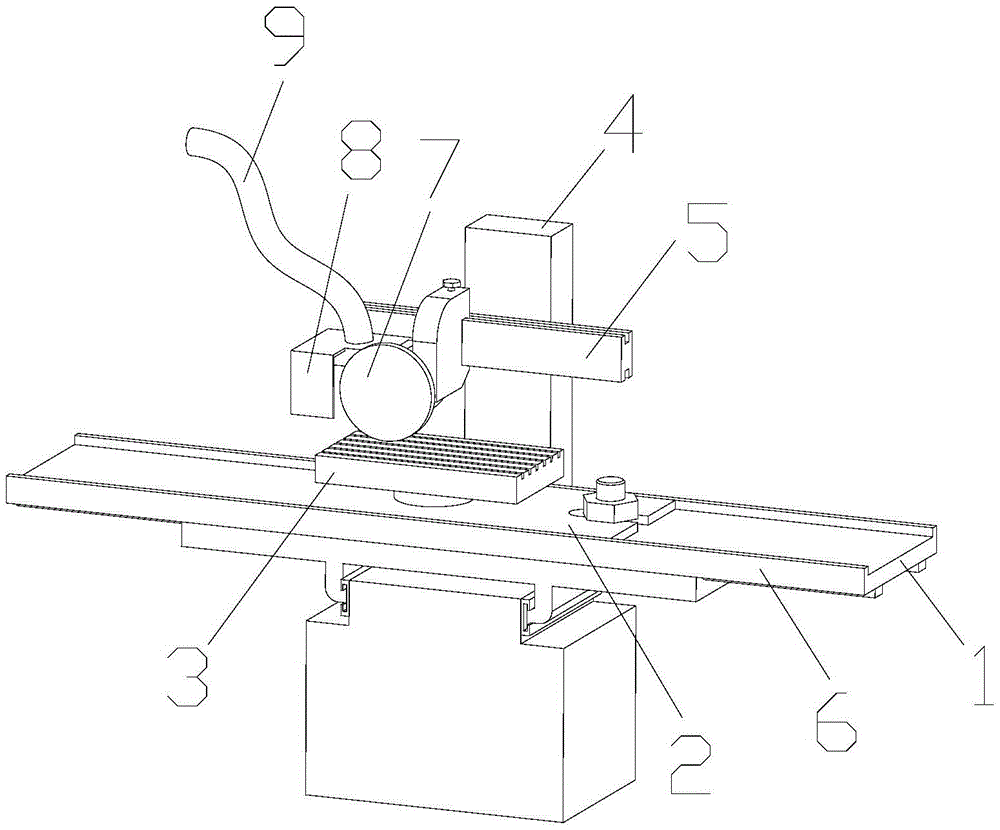

Knife tool arc edging device

InactiveCN101058160AUniform wearQuality improvementGrinding machine componentsOther manufacturing equipments/toolsEngineeringReturn work

The invention relates to a tool arc girnIt mainly comprises the body, the grinding head assembly, cross sledge, oblique angle, return working platform. It features in the grinding head and cross sledge connected to or installed on the body, oblique angle installed between the cross sledge and the return working platform which installs the sub crossing sledge with cutter carrier on it. The axial core of the oblique structure ranges within the 10 mm of the extended radius of the return shaft core and one half of the outer radius of the end surface of the sand wheel. It has strong rigidity, fine grinding quality, convenient adjustment, applicable for fine grinding.

Owner:林志贺

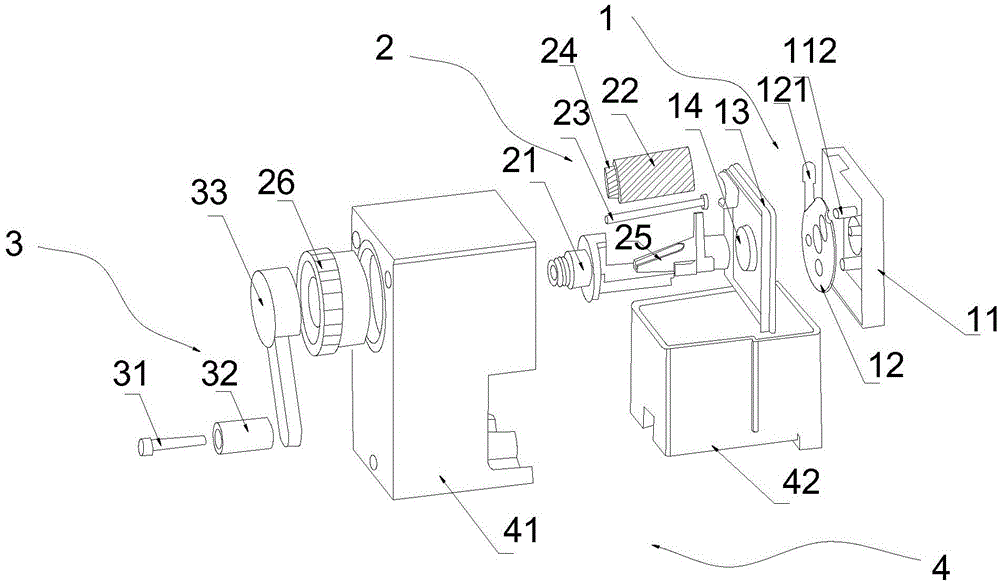

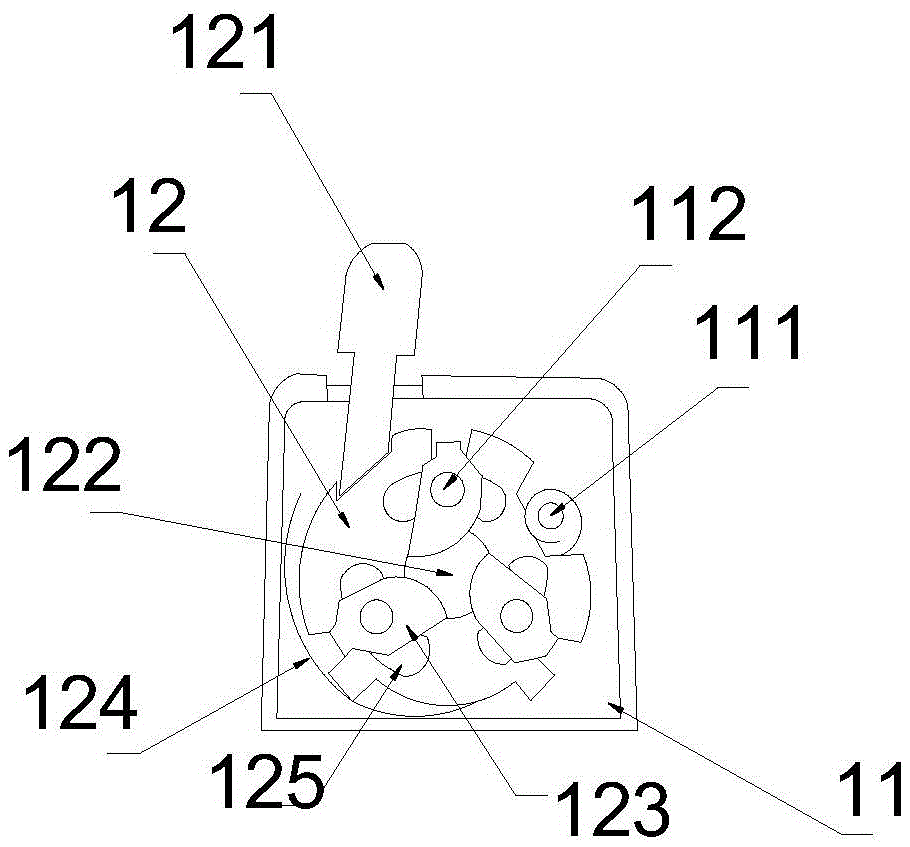

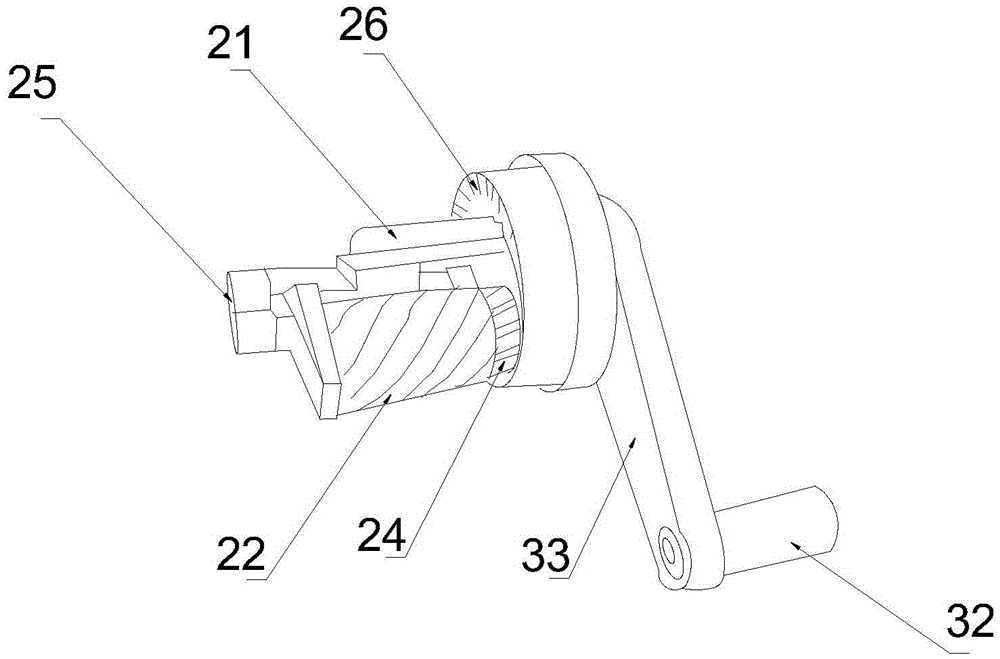

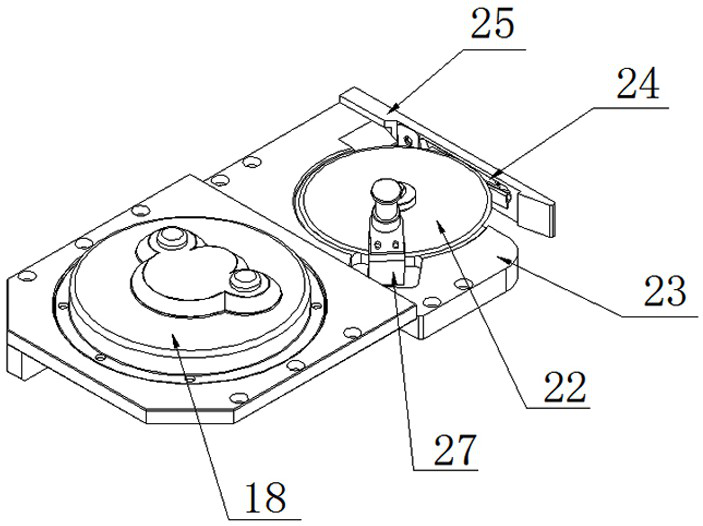

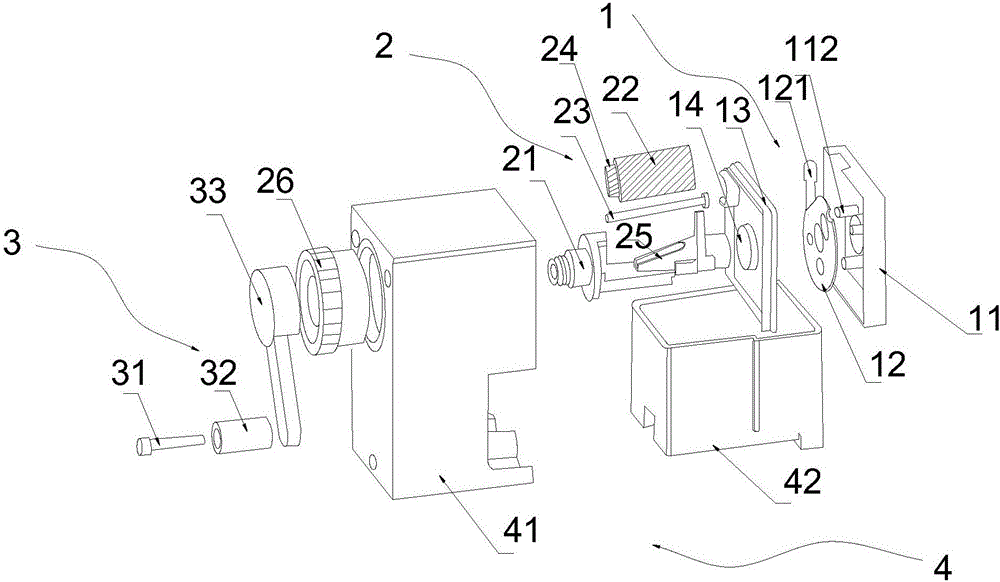

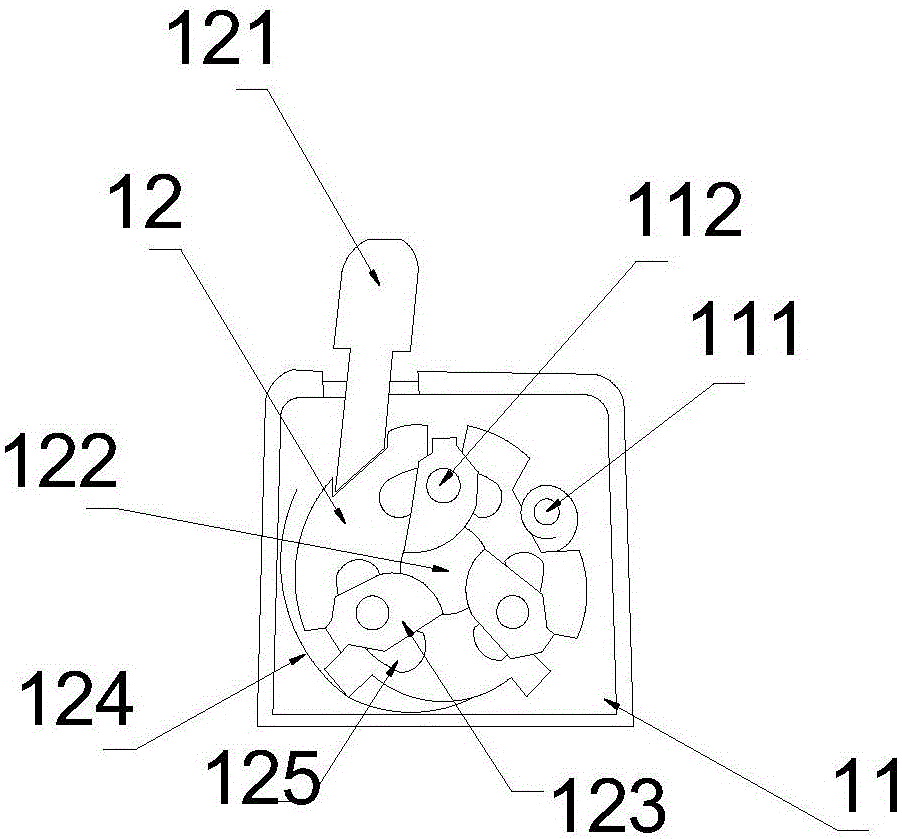

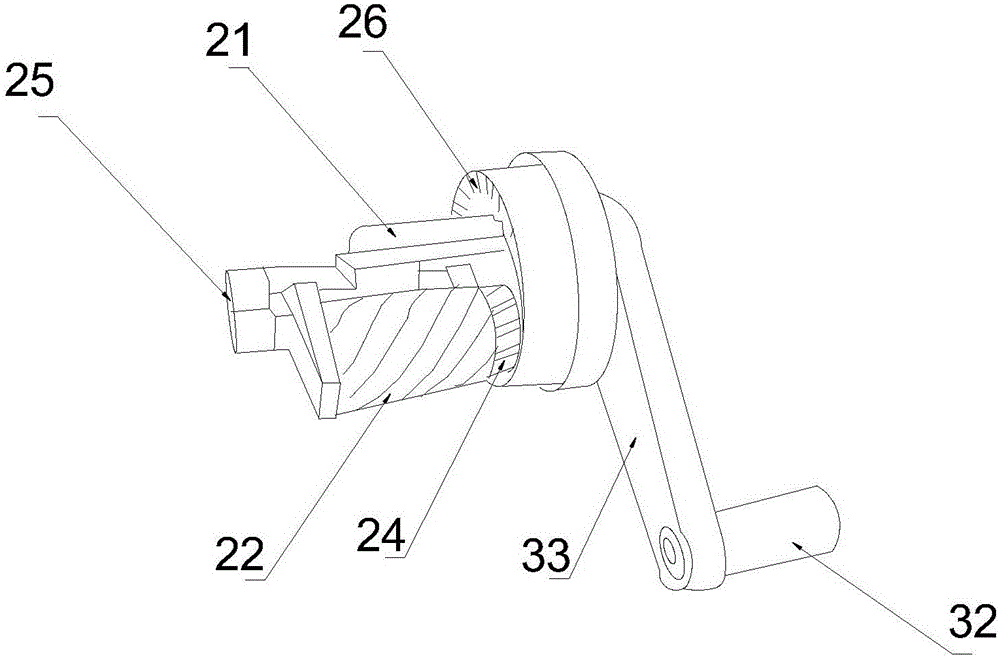

Hand-cranking type pencil sharpener

The invention relates to a hand-cranking type pencil sharpener. The hand-cranking type pencil sharpener comprises a pencil fixing module for fixing a pencil to the preset position, a pencil sharpening module for sharpening the pencil, a power module for providing power for the hand-cranking type pencil sharpener and a shell for supporting the hand-cranking type pencil sharpener; the pencil fixing module and the power module are oppositely arranged on the two sides of the shell, and the pencil sharpening module is located inside the shell; and one end of the pencil sharpening module is connected with the pencil fixing module, and the other end of the pencil sharpening module is connected with the power module. The hand-cranking type pencil sharpener is energy-saving, environment-friendly and convenient to carry; and compared with a traditional hand-cranking type pencil sharpener, the hand-cranking type pencil sharpener has the beneficial effects that the service life is long, a core is not prone to being broken, and more labor is saved.

Owner:UNIV FOR SCI & TECH ZHENGZHOU

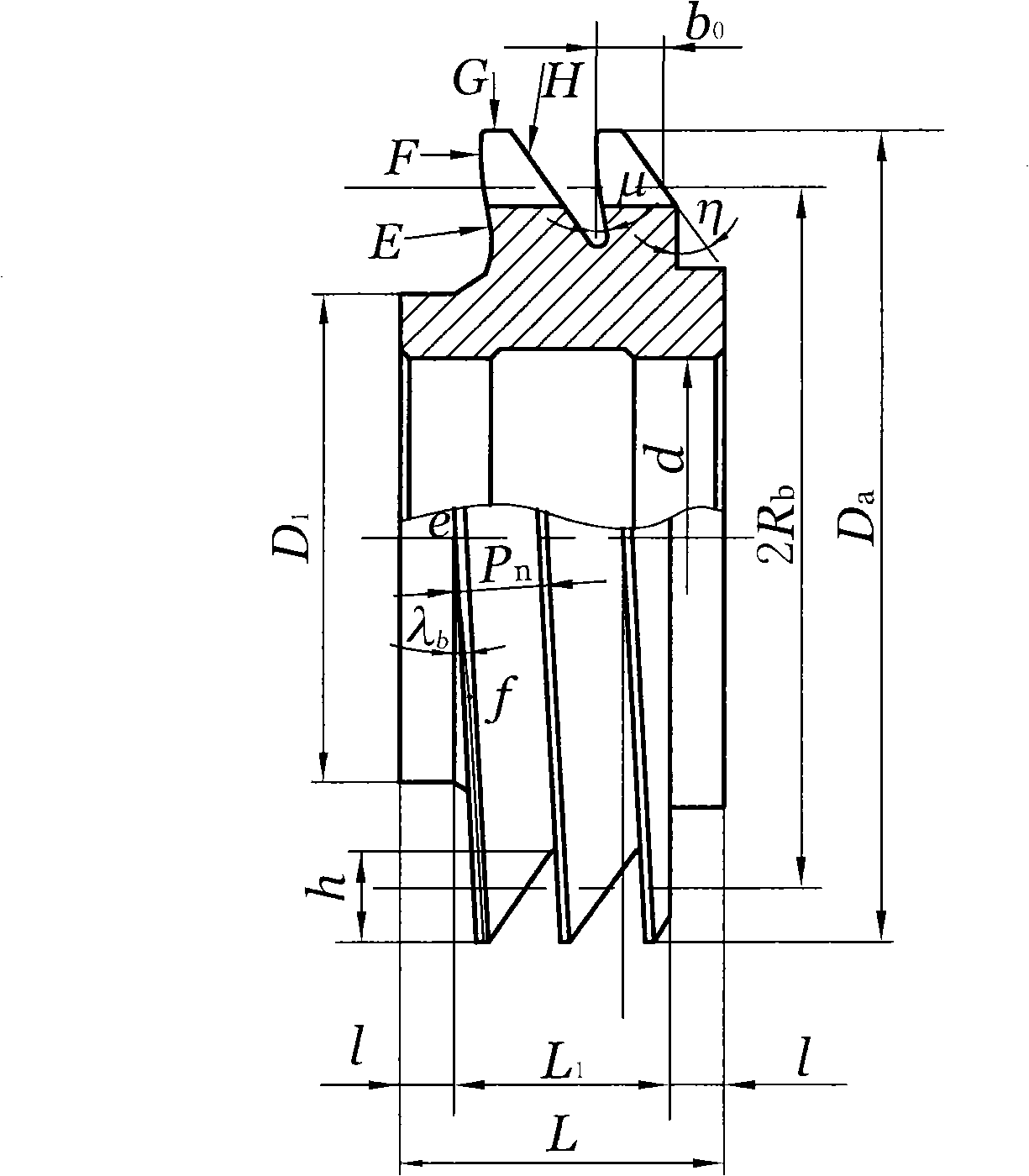

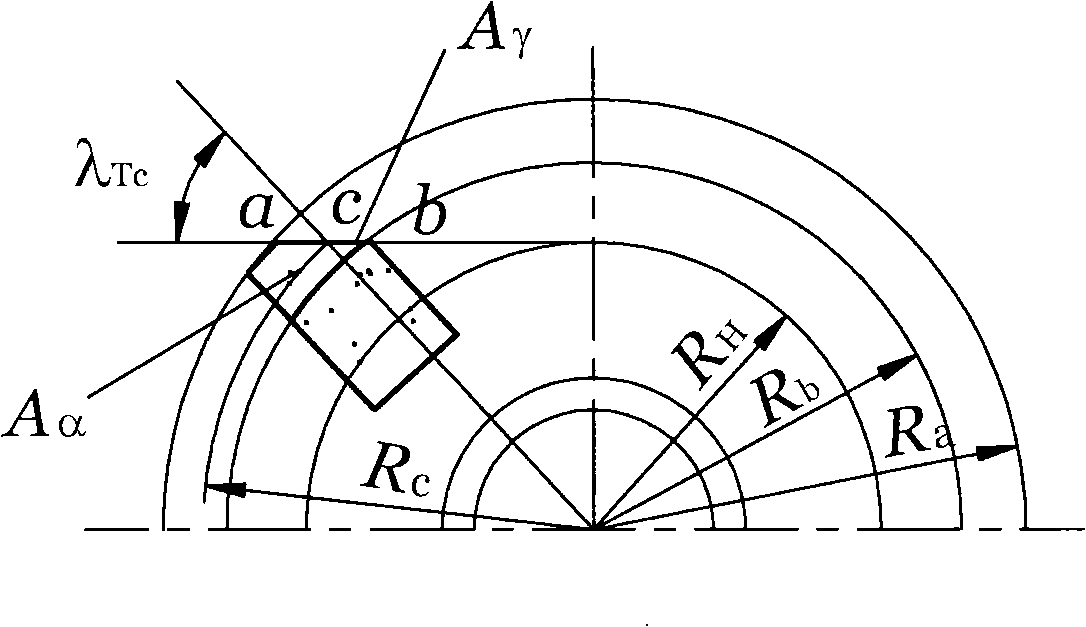

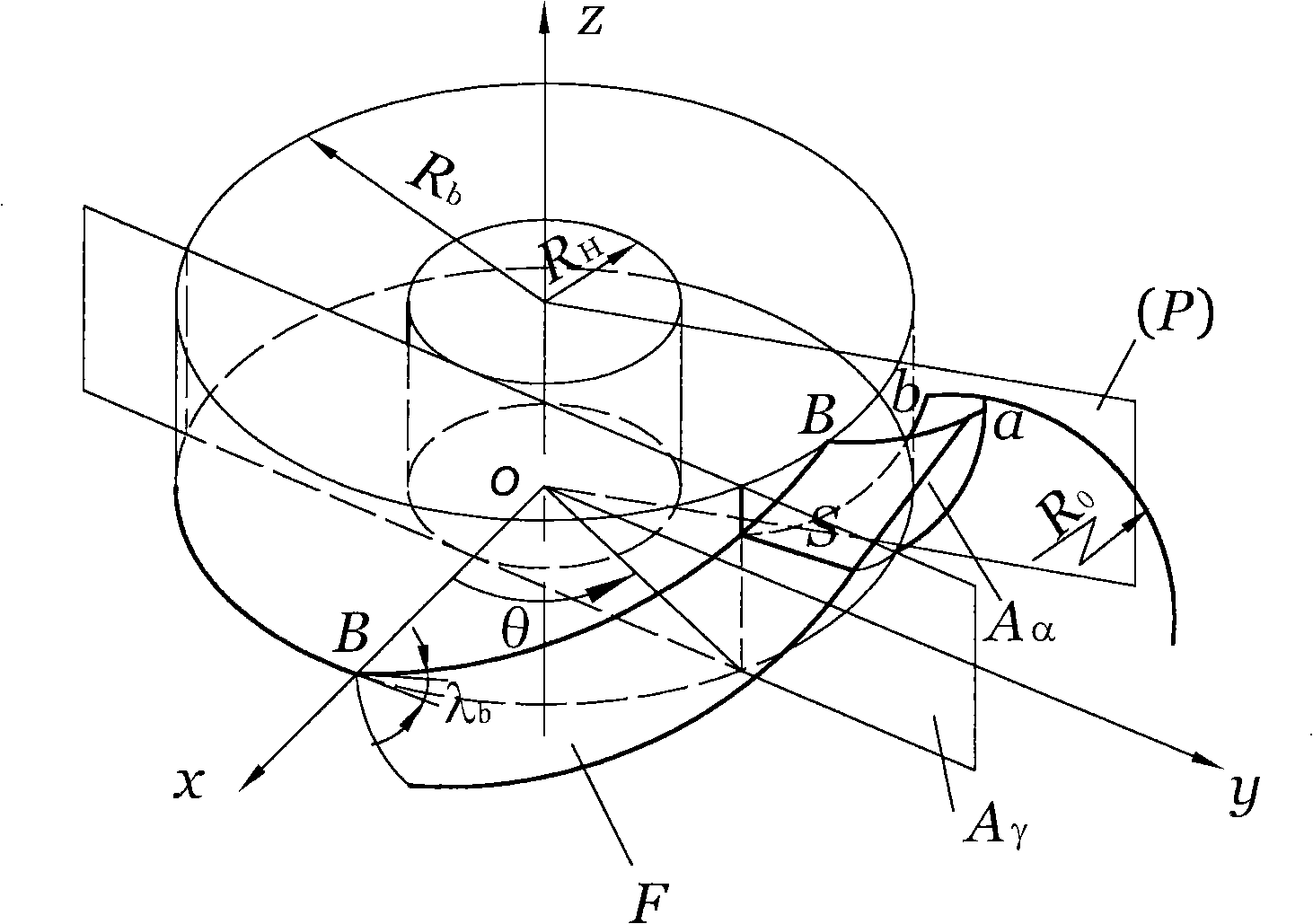

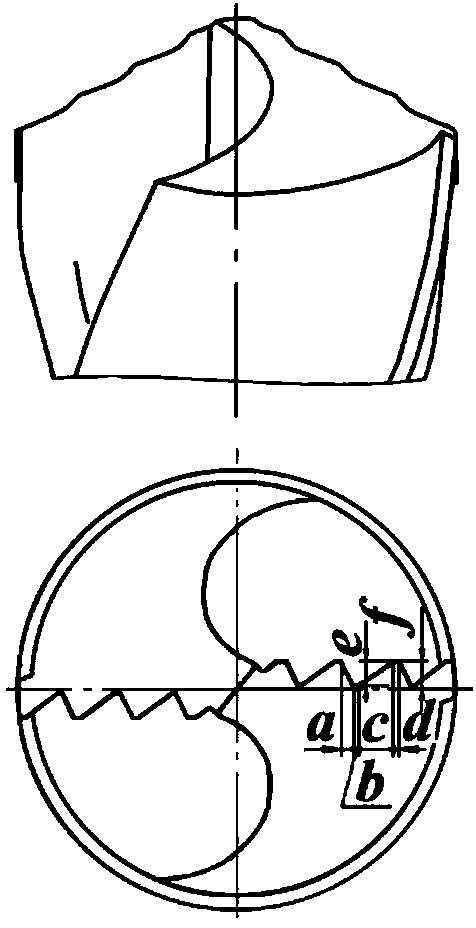

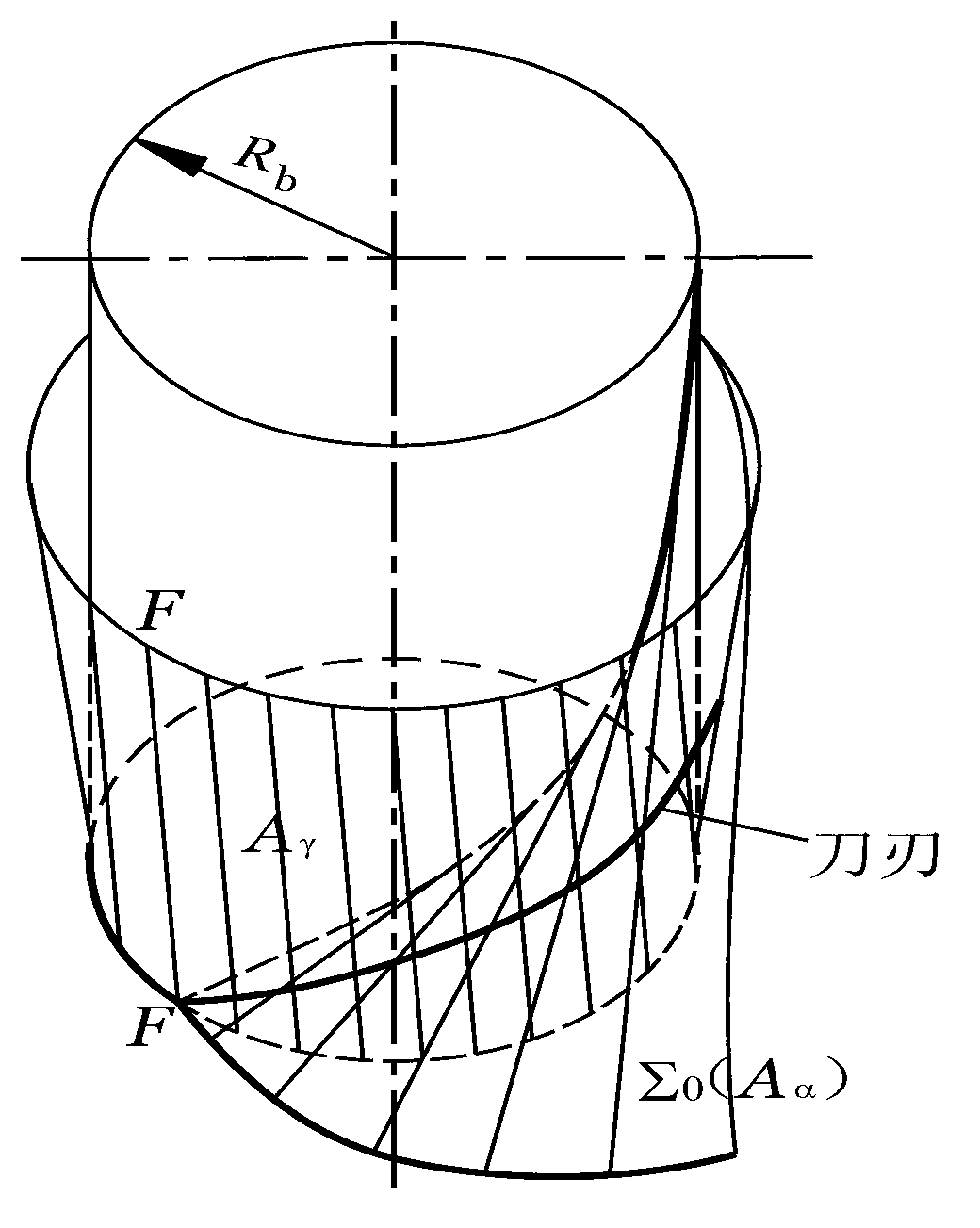

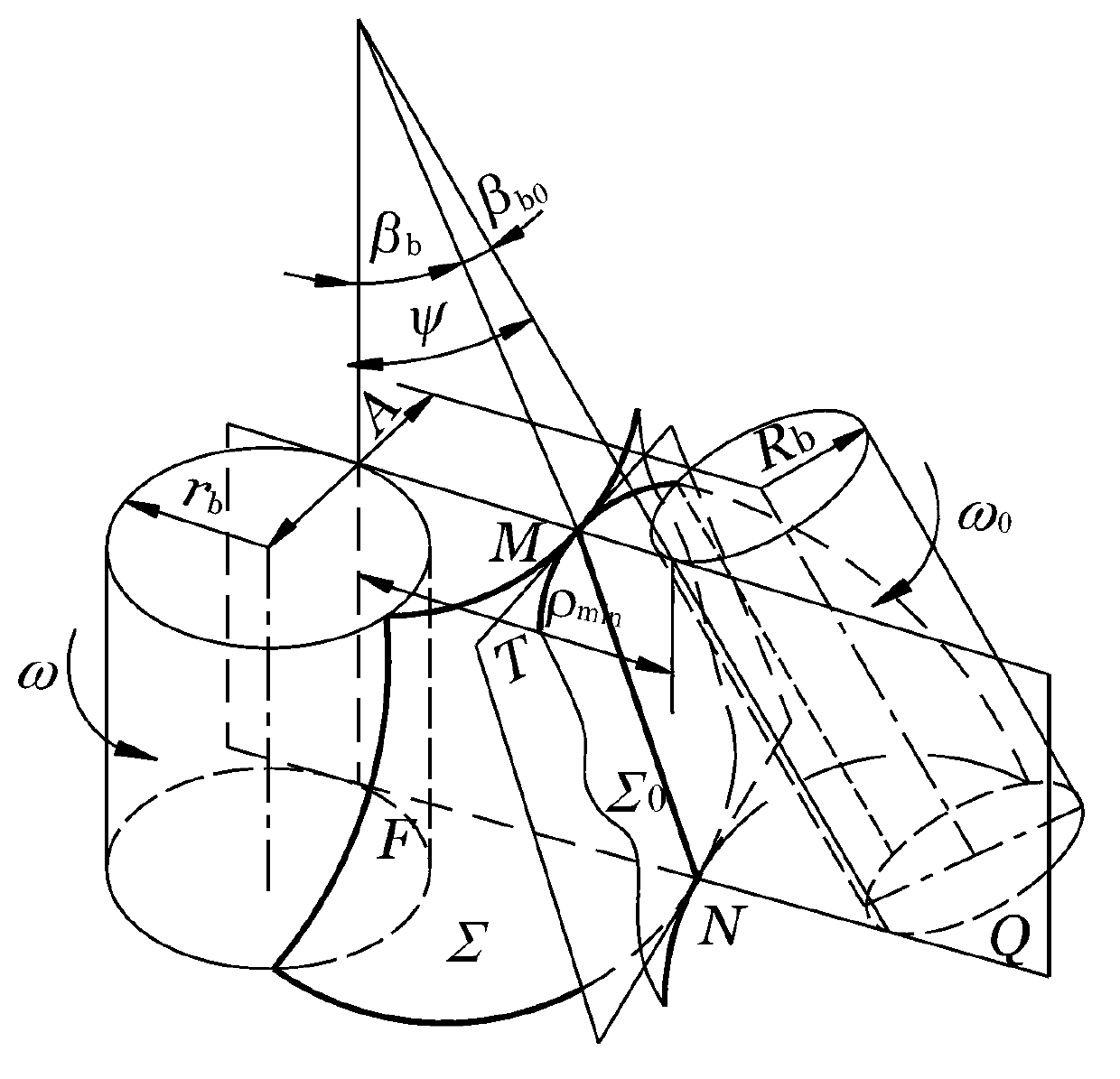

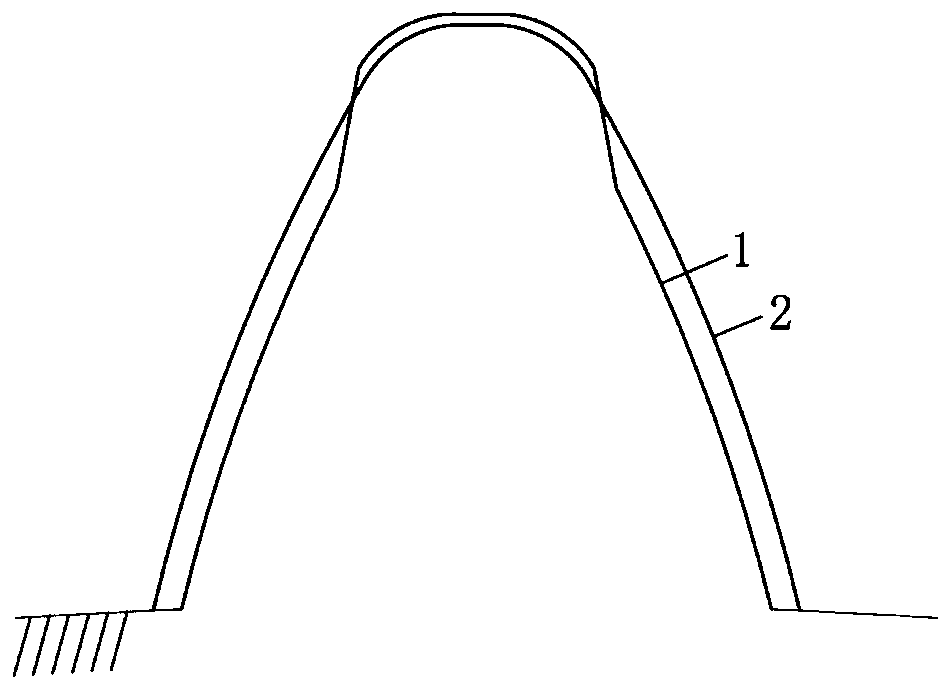

Accurate hob cutter with inserted tooth

InactiveCN101342619AEasy to GrindHigh precisionGear teeth manufacturing toolsGear teethEngineeringHeavy duty

The invention discloses an inserted finishing hob which can overcome the problem of limited cutting angle caused by selecting the different cutting edges. A basic worm of the structure is provided with a spiral groove with headage i, lead p and groove depth h. Rb is the radius of the base cylinder of the basic worm. A line outside the base circle at the working side which is tangent to the base cylinder with the radius Rb and has the inclination angle Lambda b with the top surface of the base cylinder, is utilized as the generating line, and the generating line rolls along the base cylinder to form an involute helicoid, and the involute helicoid is the generating flank (F) of the hob of the basic worm configuration. Z gullets of the basic worm are respectively fixedly provided with a cutter tooth block which is uniformly positioned on the helical tooth of the basic worm. The front face of the hob Agamma is the plane and is tangent to the cylindrical surface of a mill knife with the radius RH. The intersection line of the generating flak of the basic worm (F) and the front face of the hob Agamma is the cutting edge of the hob (S), and the circle surface formed by the cutting edge of the hob (S) revolving around the axis oz is utilized as the back face of the hob Aalpha. The inserted finishing hob is more suitable for the finish machining of large modulus and heavy-duty gear.

Owner:JILIN UNIV

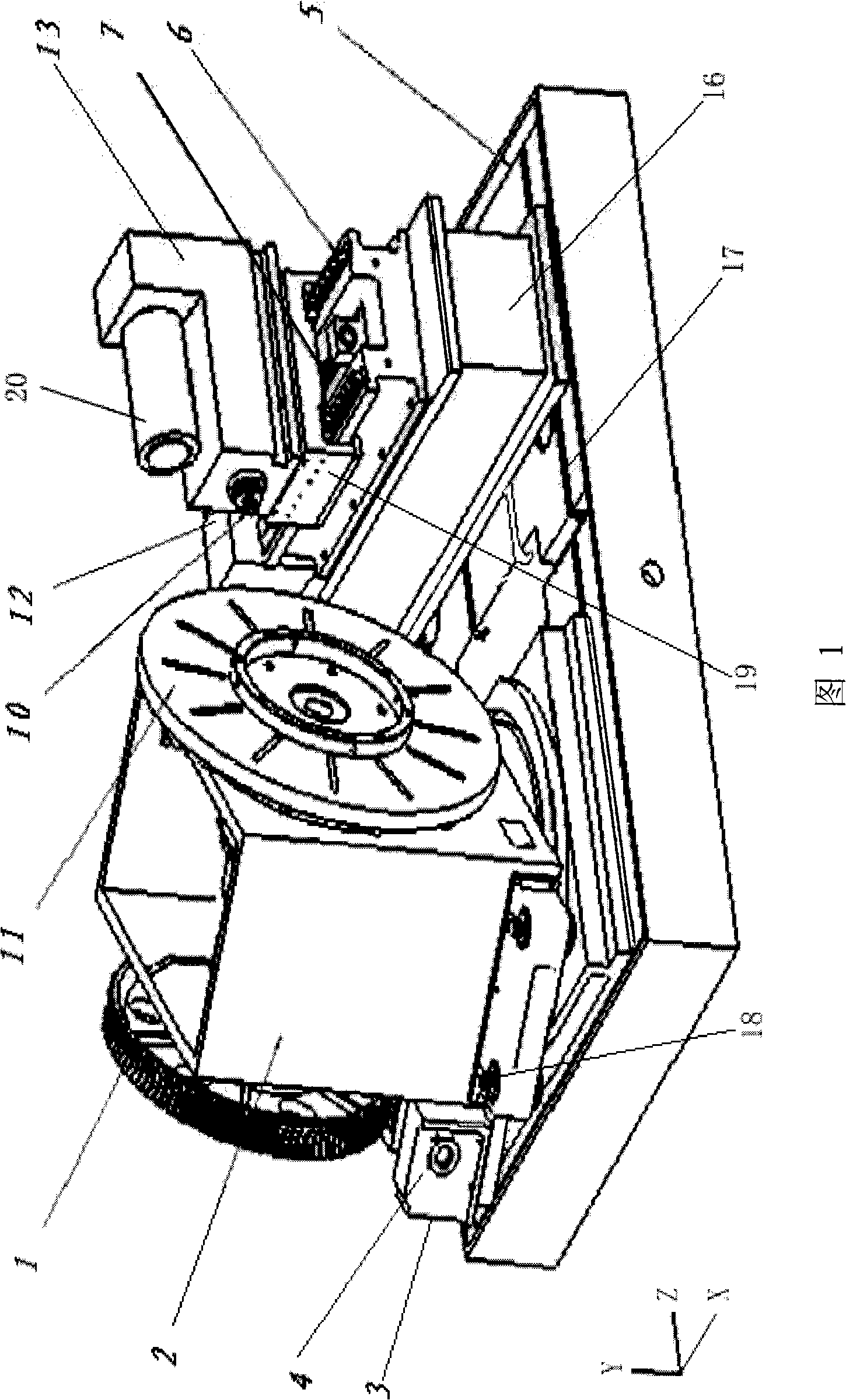

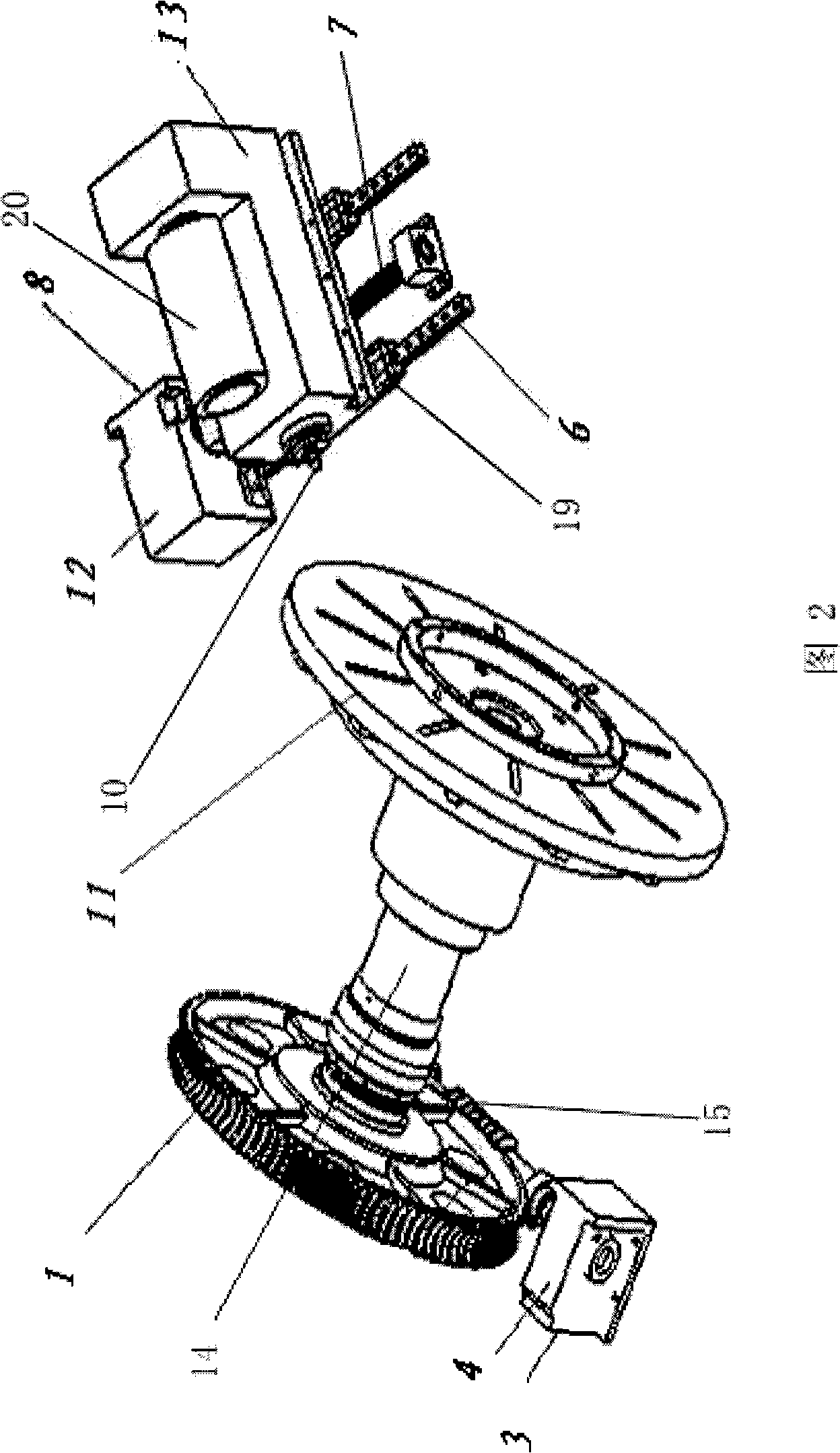

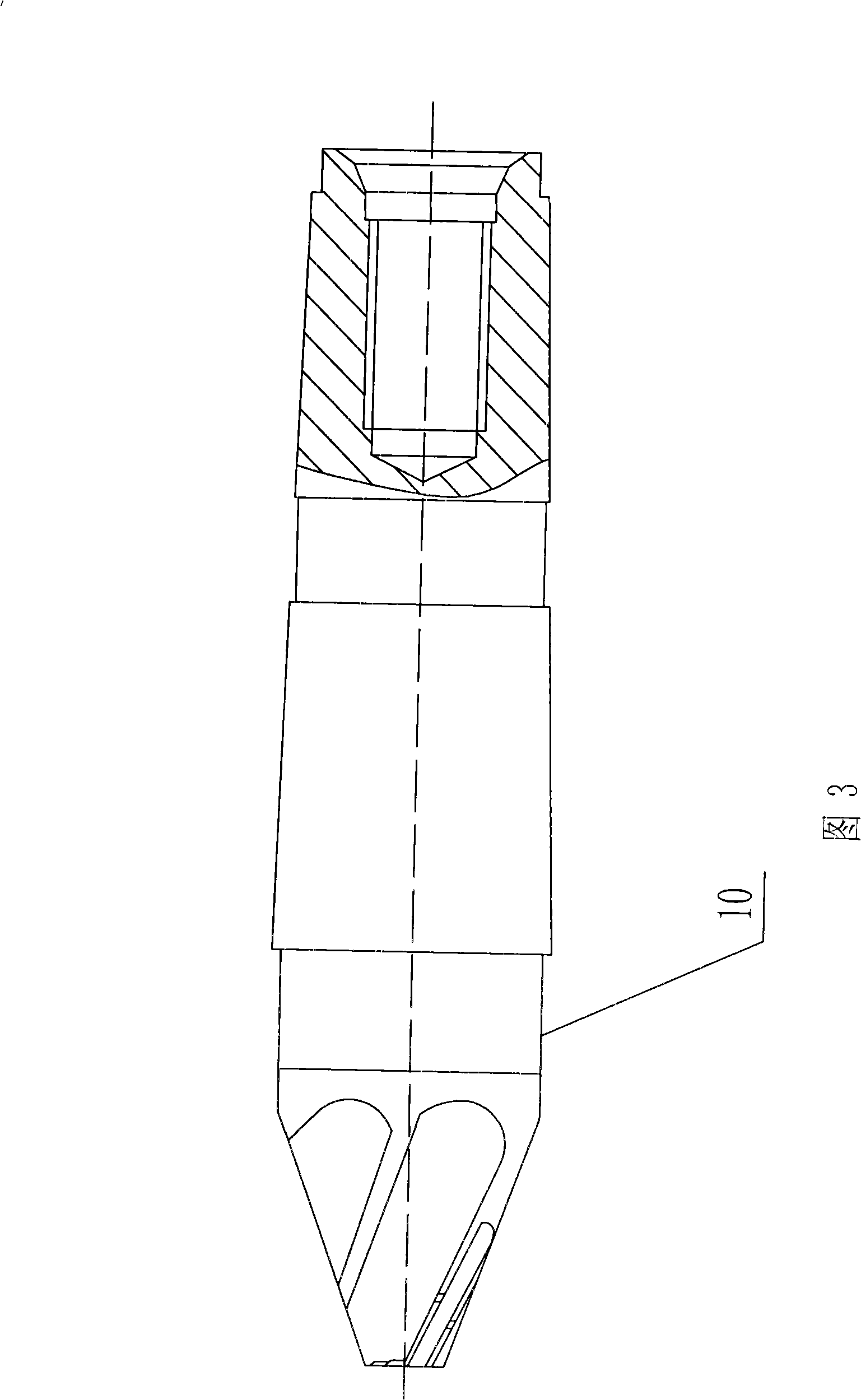

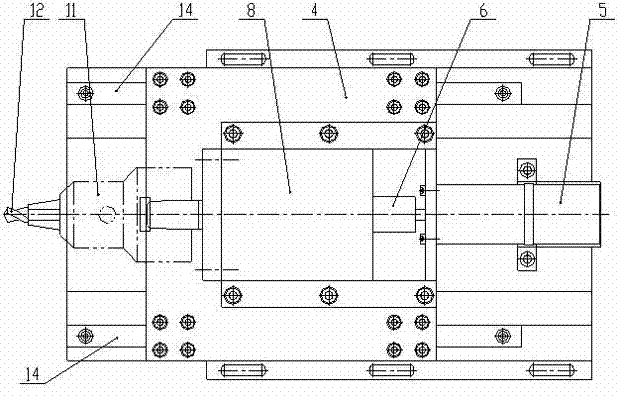

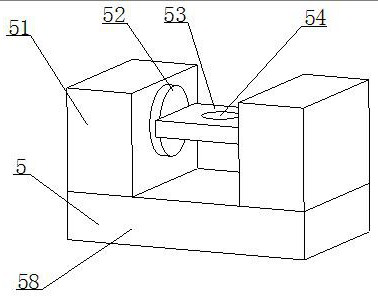

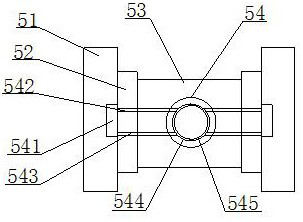

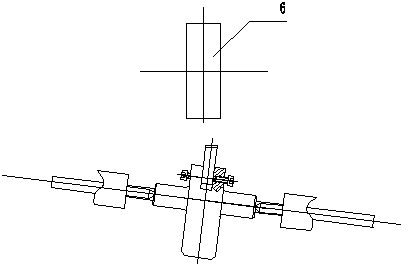

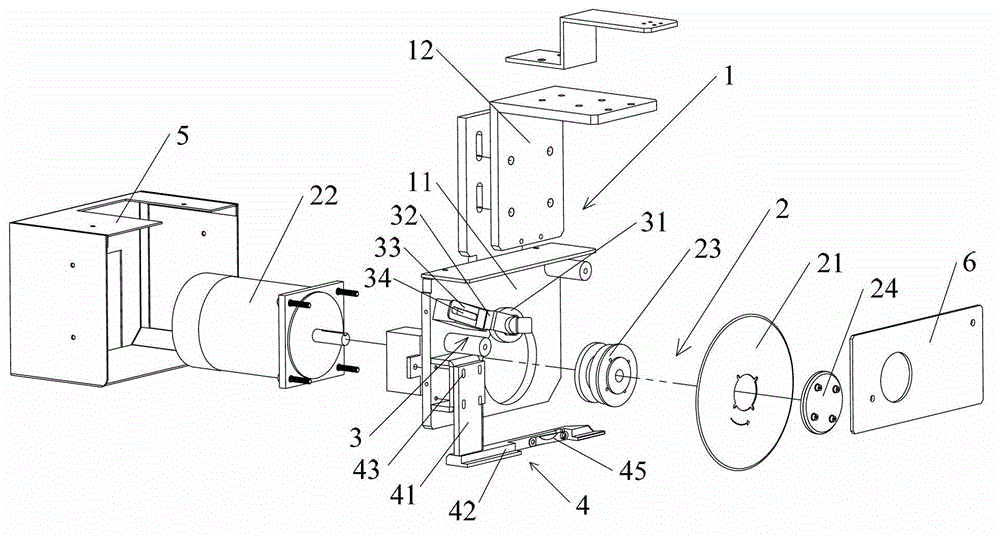

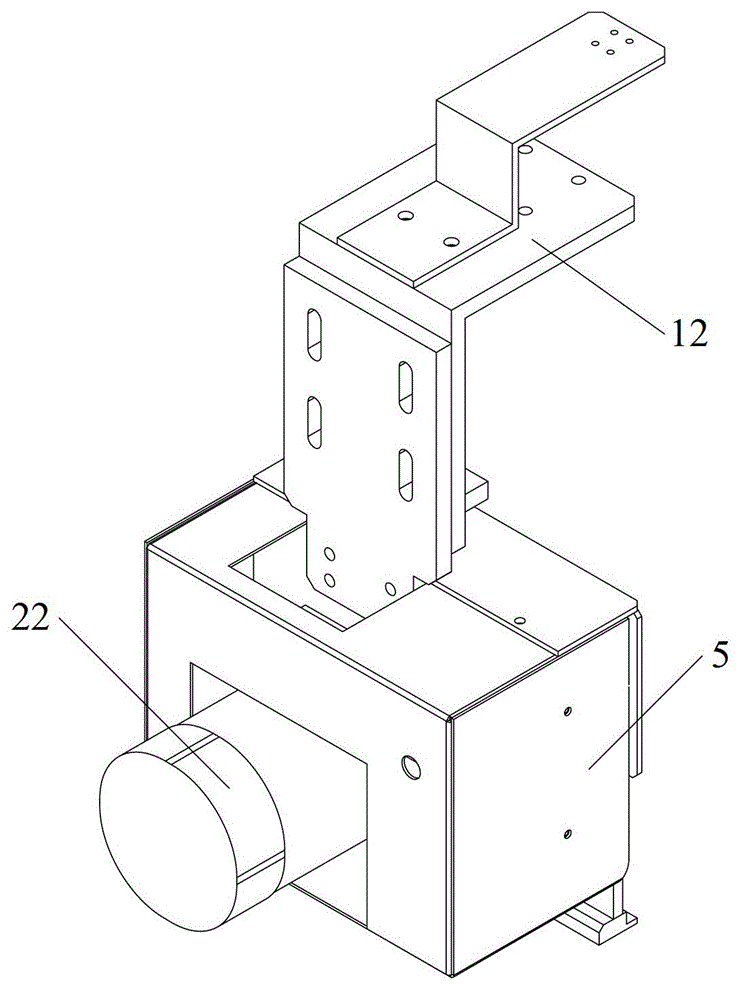

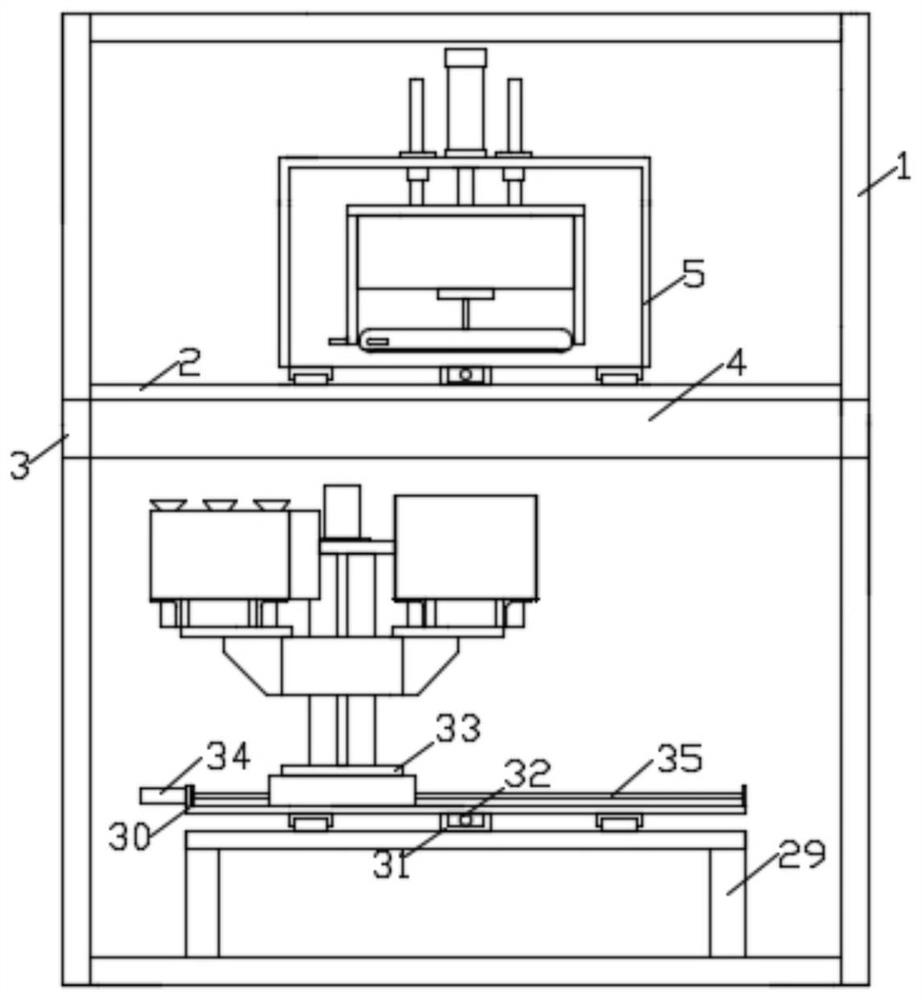

Finger cutter type helical bevel gear processing device

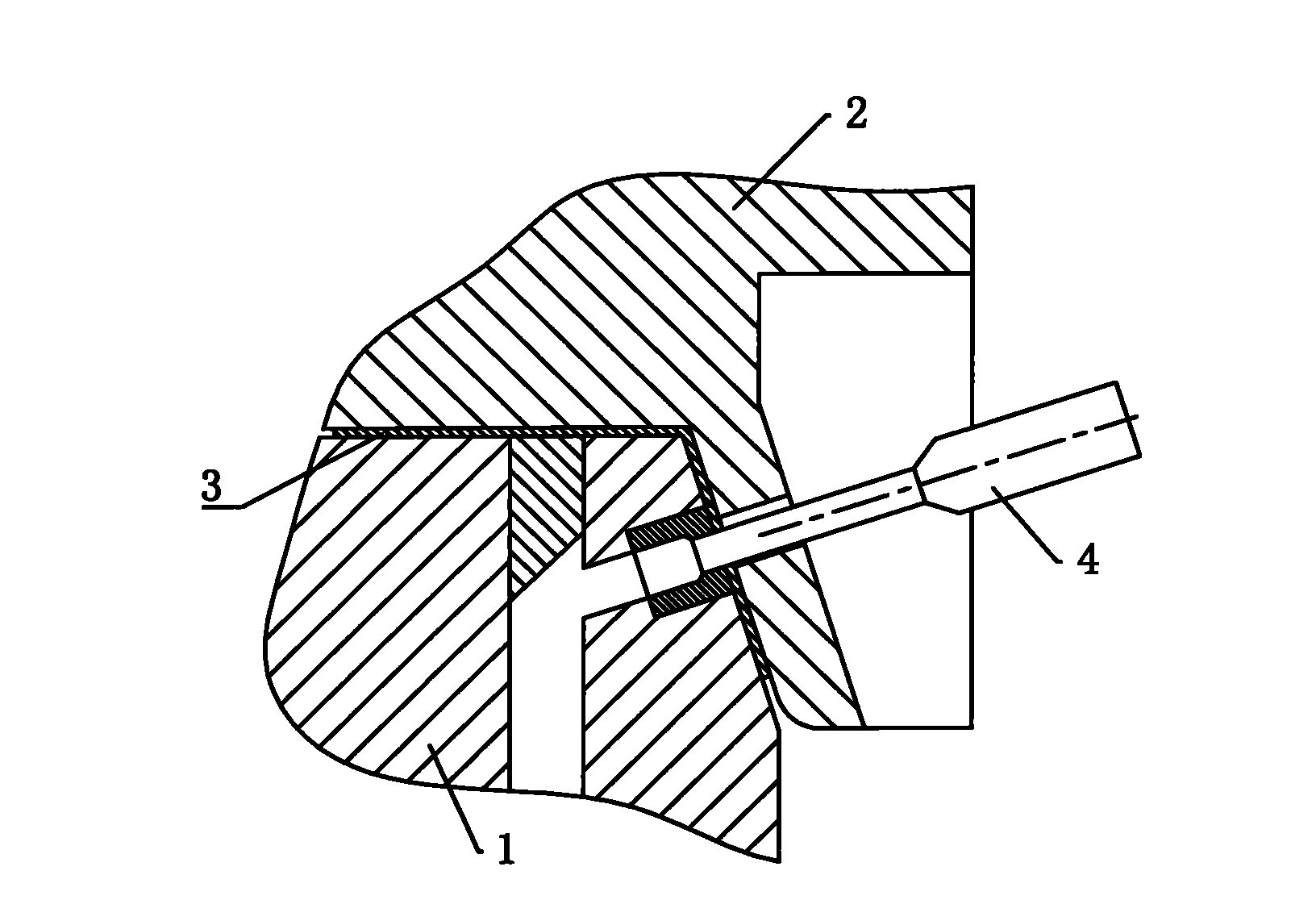

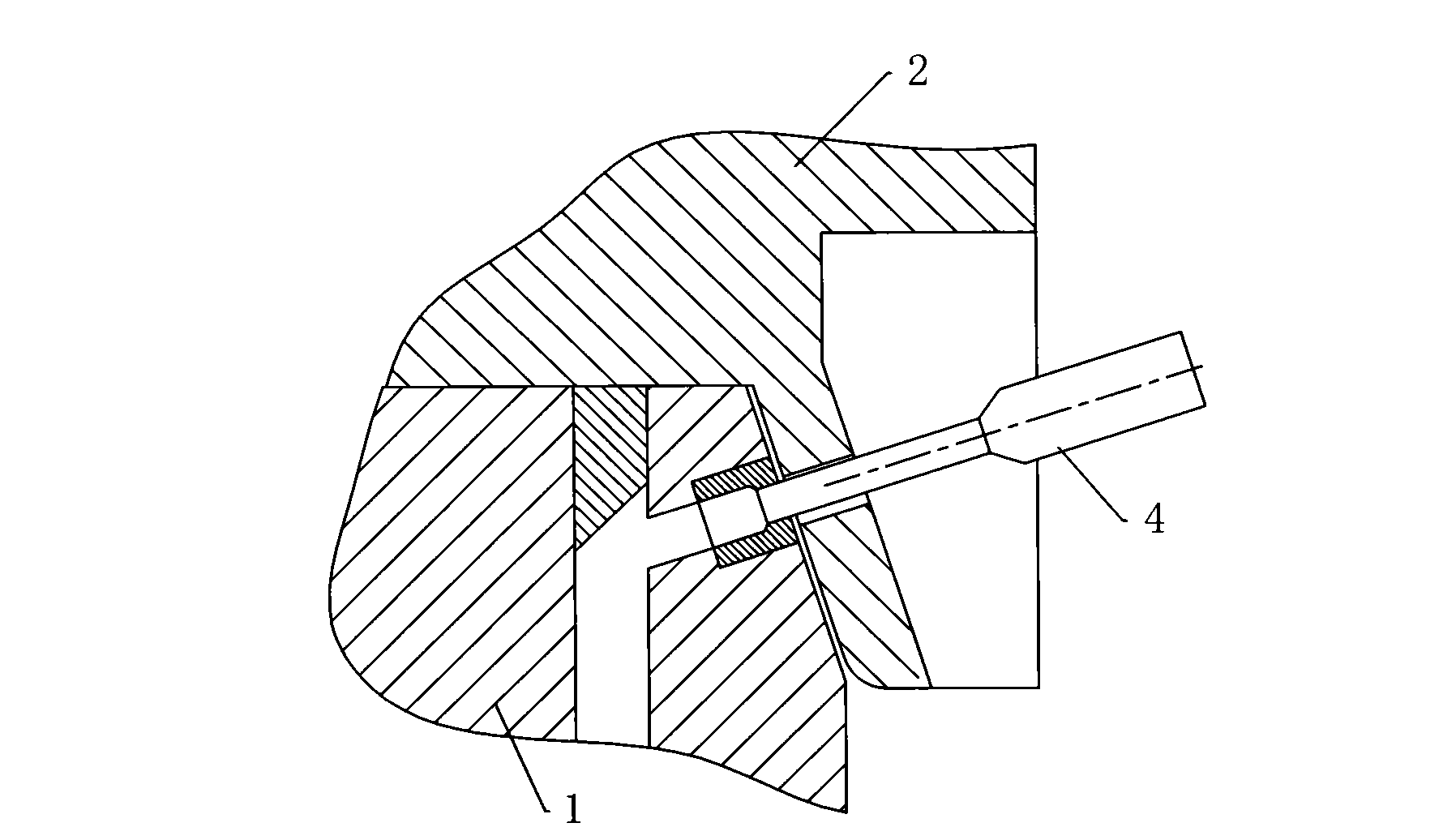

InactiveCN101342614AEasy to adjustSimple structureFeeding apparatusLarge fixed membersMilling cutterFeed drive

The invention discloses a finger-like milling cutter type machining device of spiral bevel gear comprising a machine body (5). The two sides of the body (5) are respectively provided with a space-adjustable workpiece box component and a cutting tool box component. The workpiece box component comprises a workpiece box (2), a workpiece spindle (14) and a driving mechanism for the workpiece spindle. The cutting tool box component comprises a spindle of cutting tool for driving the finger-like milling cutter to rotate and a driving mechanism of the spindle of cutting tool. The workpiece box (2) rotates around the vertical axis Y and is positioned on the machine body (5). The workpiece box (2) is provided with a positioning device for fixing and positioning the machine body (5). The cutting tool box also comprises a cutting tool base (16) which is positioned on the machine body (5), and a cutting tool feeding skid (19) which is movably positioned a X-directional straight guide rail (6) on the cutting tool base (6). The cutting tool spindle is positioned on the cutting tool feeding skid (19) which connects the feed driving mechanism. The finger-like milling cutter type machining device of spiral bevel gear has the advantages of short transmission chain, not requiring the mechanical transmission, high accuracy and good flexibility of program control.

Owner:洛阳科锐机电设备有限公司 +1

Device for spirally grinding back knife face of spiral drill based on electrospark wire cutting

The invention provides a device for spirally grinding a back knife face of a spiral drill based on electrospark wire cutting, which comprises a spiral drill, a rotary shaft, a ball screw nut pair, a rolling guide pair and a rack; the spiral drill is mounted at one end of the rotary shaft by a spanner three-jaw drill chuck; the other end of the rotary shaft is connected with a first step motor through a shaft coupler; the rotary shaft is mounted in a bearing seat by a bearing; a connecting plate is fixed to the bottom of the bearing seat; the ball screw nut pair is composed of a screw rod and a nut sleeved to the screw rod; the screw rod is connected to a second step motor; the nut is fixedly connected with the connecting plate; the rolling guide pair is composed of a groove arranged on a rolling guide block and a guide embedded in the groove; the rolling guide block is fixed to the bottom of the connecting plate; and the guide is fixed to the rack. The device provided by the invention has the advantages that: the device may not cause grinding burn injury of the back knife face for no grinding force, is not influenced by knife materials and knife sizes and can grind spiral drills of various conductive knife materials and sizes.

Owner:SHAANXI UNIV OF TECH

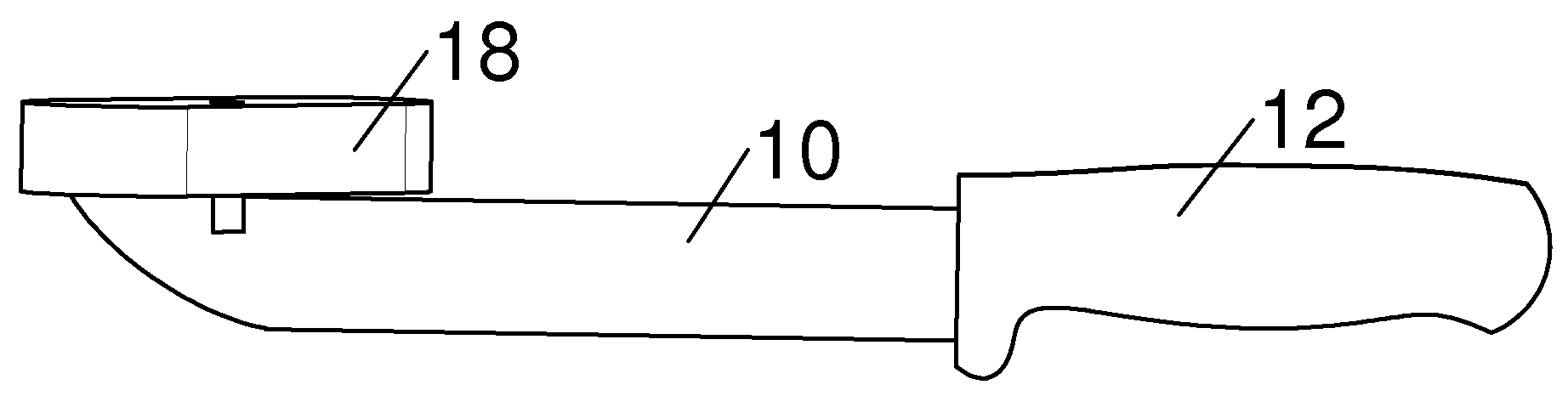

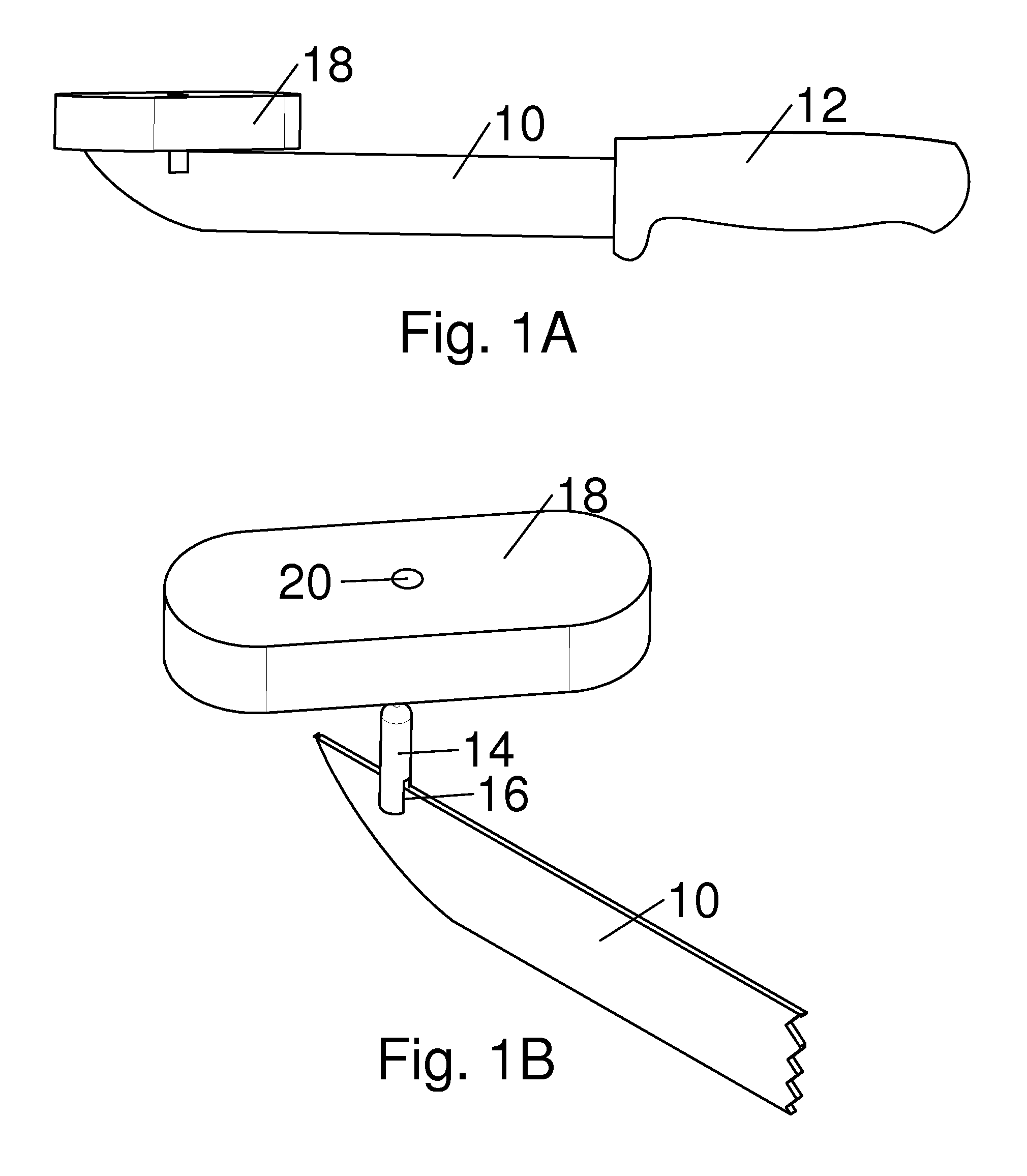

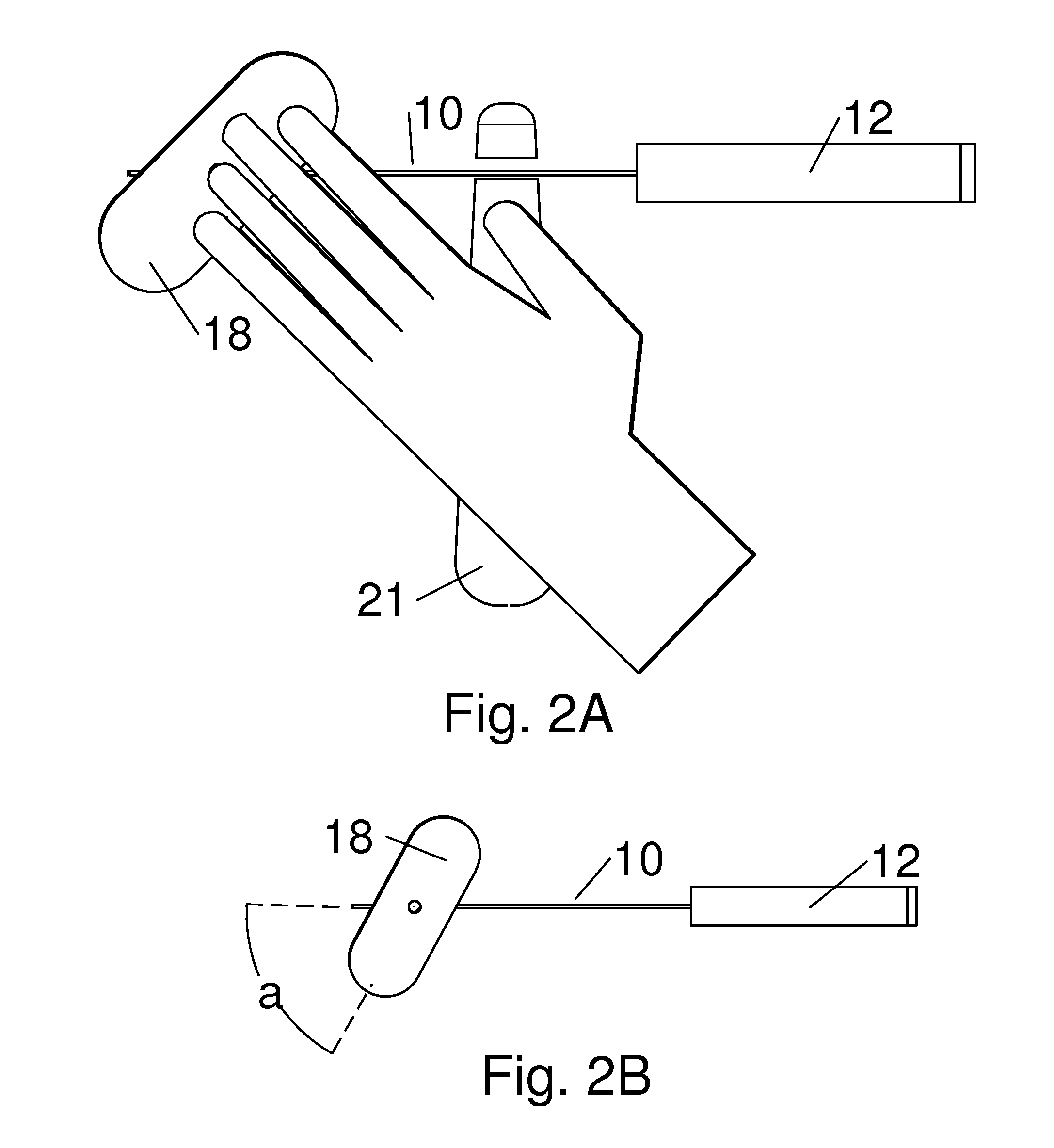

Double Handle Kitchen Knife

InactiveUS20090139098A1Easy to use with one handEasy to cleanMetal working apparatusMetal-working hand toolsLong axisEngineering

A double handle knife is described with the secondary handle rotatable upon a pivot post. In further embodiments: the secondary handle is mounted to the top of the blade at a fixed angle of 45 degrees (+ or −25) degrees between the long axis of the secondary handle and the long axis of the knife blade; and attachments are described to convert single handle knifes into double handle knives functioning identical to those described above.A methods is described utilizing the double handle knife invention in any of its embodiments being gripped by the dominant hand on the primary handle, four fingers of the non-dominant hand being placed evenly upon the secondary handle with long axis thereof positioned at an angle of 45 degrees (+ or −25) degrees to the long axis of the knife blade, the palm / or thumb of the same hand positioning the food item, both hands applying downward pressure and the food item being easily and accurately cut.

Owner:HAYES BRIAN WILLIAM

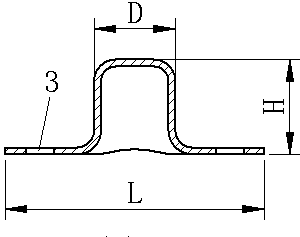

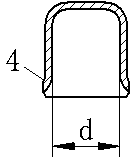

Machining method for protection cover part

InactiveCN103978101ASimple structureEasy loading and unloadingShaping toolsPunchingStructural engineering

The invention discloses a machining method for a protection cover part. The protection cover part is punched and formed through a J23-16T punching machine, and an elliptical or rhombus sheet is used for a protection cover part punching blank; the punching process is divided into cover forming, shaping and punching and edge cutting; the cover is formed through punching through a flange-free cylindrical tension die, and the cover is punched into a cylinder large in the outer diameter and low in height; a flange-free cylindrical tension die of different size is changed to be punched continuously to reduce the cover diameter and increase the cover height till the cover diameter and height approach the design sizes gradually to complete the cover forming stage; changing the shaping die, punching the diameter and the height of the cover into the final design size through a flange cylindrical tension die, punching flanges, and performing punching and edge cutting through a punching and edge cutting composite die. According to the machining method, the shaping quality is good, lubrication is performed without lubricants during tensioning, and annealing treatment is not needed during tensioning; processes can be shortened, dies are reduced, and the product efficiency is improved.

Owner:GUIZHOU AEROSPACE PRECISION PRODS

End face ring-type deep groove machining cutter

The invention discloses an end face ring-type deep groove machining cutter which comprises a cutter body and a blade. The cutter body comprises a cutter handle matched with a machine tool tailstock hole and a barrel-shaped blade seat connected with the cutter handle, one end of the blade seat is fixedly connected with the cutter handle, the tail end of the other end of the blade seat is provided with a notch, and the barrel wall, corresponding to the notch, is fixedly connected with the blade. According to the end face ring-type deep groove machining cutter, the structure is simple, due to the fact that the large-area notch is formed in the barrel-shaped blade seat, the chip removing speed and the chip retreating speed are increased, and the production efficiency is improved; meanwhile, the wall thickness of the barrel-shaped blade seat is decreased, so that the barrel-shaped blade seat does not make contact with a workpiece, the energy loss in the machining process is reduced, and heat generated through friction is reduced; meanwhile, cooling liquid can be added from a gap between the barrel-shaped blade seat and the groove wall of a workpiece deep groove if necessary, the temperature of a formed workpiece is lowered, the cooling time is reduced, and the production efficiency is improved.

Owner:张家志

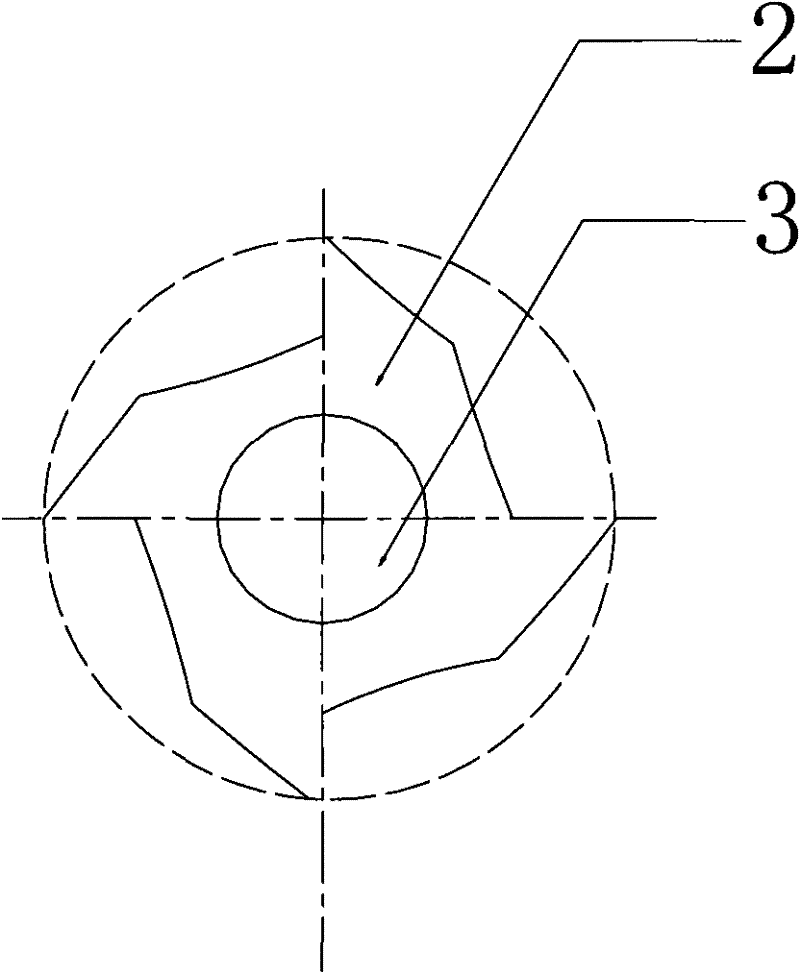

Twist drill with grooved front tool faces and bent blades

ActiveCN103737073AImprove drilling performanceEasy to save energyTwist drillsPolygonal lineEngineering

The invention discloses a twist drill. The twist drill is characterized in that main blades of the twist drill are bent blades, in other words, a plurality of spiral grooves are formed in spiral surfaces of front tool faces of the main blades, projection of each spiral groove on an end plane of the twist drill is a curve or a fold line which is used as a generating line, and the spiral grooves spirally move around a drill spindle from the generating lines. The invention further discloses application of the twist drill to drilling machining. The twist drill and the application have the advantages that the twist drill is excellent in comprehensive drilling performance, holes can be drilled and machined within a short time, the twist drill is low in drilling power consumption and high in tool durability, and a tool sharpening method is simple and convenient and is easy to implement.

Owner:HUAZHONG UNIV OF SCI & TECH

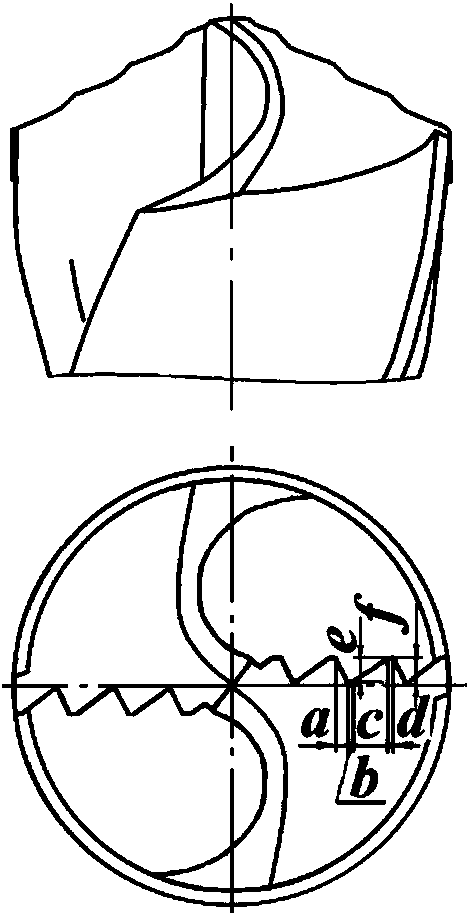

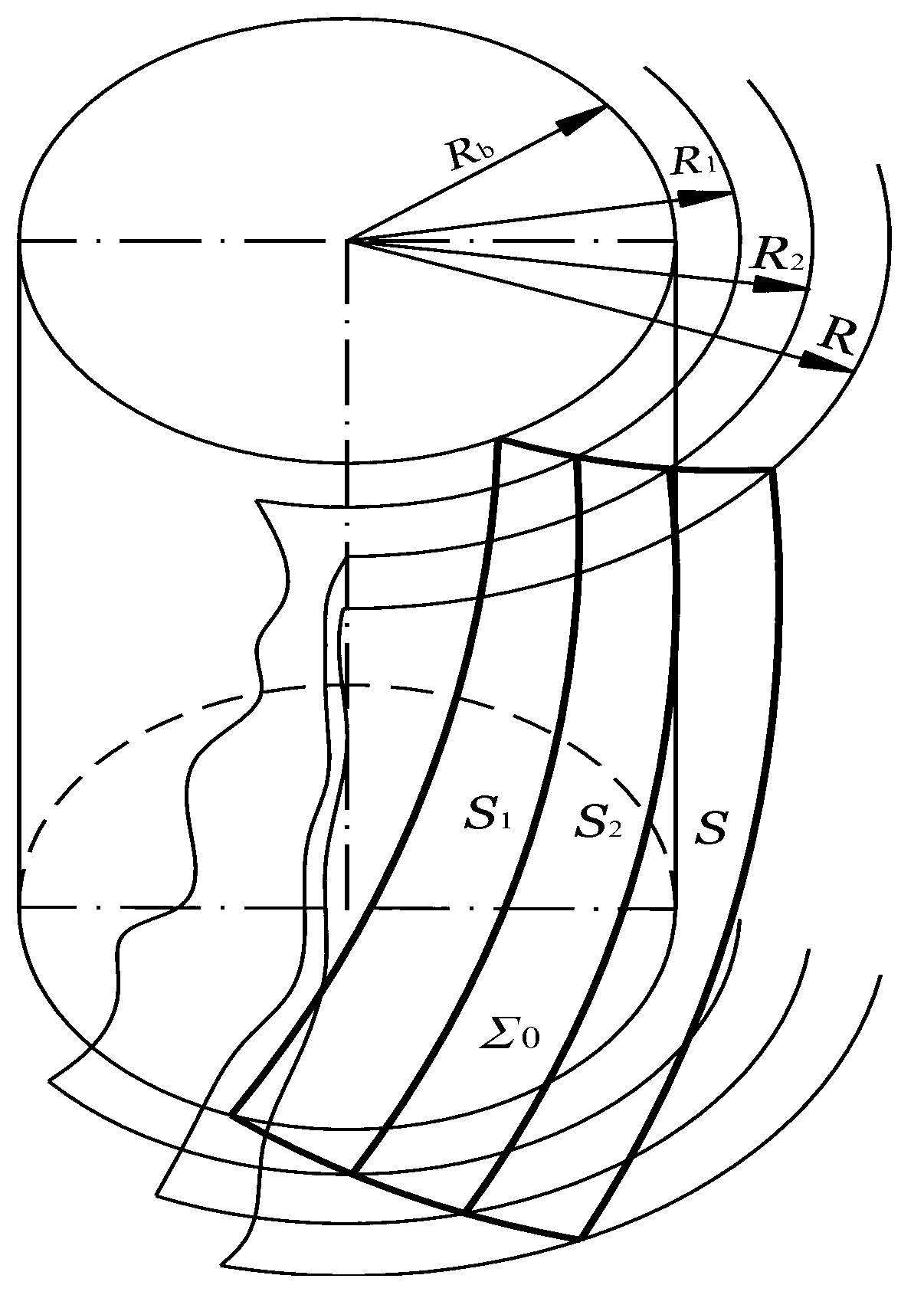

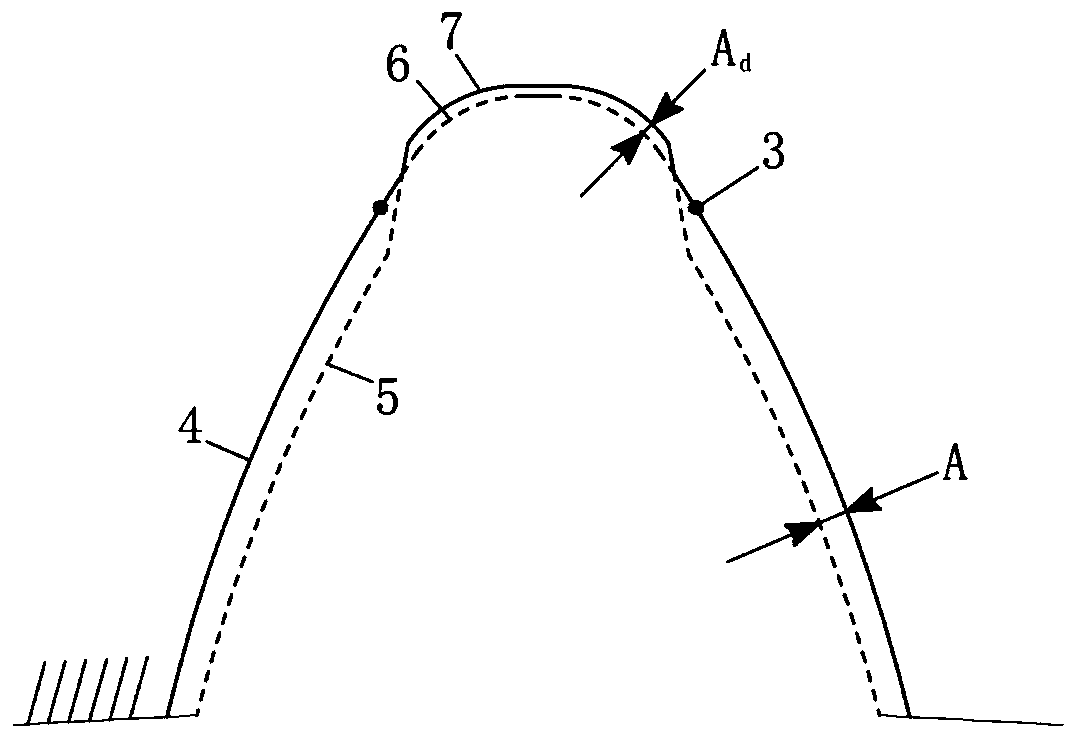

Design method of 0-degree tooth profile angle helical tooth finish turning gear shaving cutter

InactiveCN103100764ASimple insertsSimple calculationGear teeth manufacturing toolsGear teethEngineeringTooth number

The invention discloses a design method of a 0-degree tooth profile angle helical tooth finish turning gear shaving cutter. The design method comprises the following steps of: (1) confirming a radius Rb of a base circle: according to the structure of a used machine tool and a cutter, confirming the Rb; (2) selecting value of a base circle helical angle beta b 0: beta b 0 being from 10 degrees to 20 degrees; (3) confirming the helical direction which is consistent with the helical direction of a machining gear; (4) preliminarily calculating the number of teeth z0 of the cutter; (5) accounting an actual base circle helical angle; (6) confirming a radius R of an outer circle: R=R*b+ delta R; (7) confirming the width B of the cutter; (8) confirming a cutter tooth groove spiral lead P; (9) confirming a cutter blade normal relief angle alpha N; (10) confirming a cutter tooth groove normal section angle epsilon, and value of the epsilon ranging from 25 degrees to 30 degrees; (11) confirming the tooth top width b of the cutter tooth: b=mn; (12) confirming the groove depth h of the cutter tooth: h= (2.25-2.3)mn; (13) confirming the radius r1 of a tooth top arc of the end face: r1=0.25mn; and (14) confirming the radius r2 of a groove bottom arc of the cutter tooth: r2= (0.25-0.3)mn.

Owner:JILIN UNIV

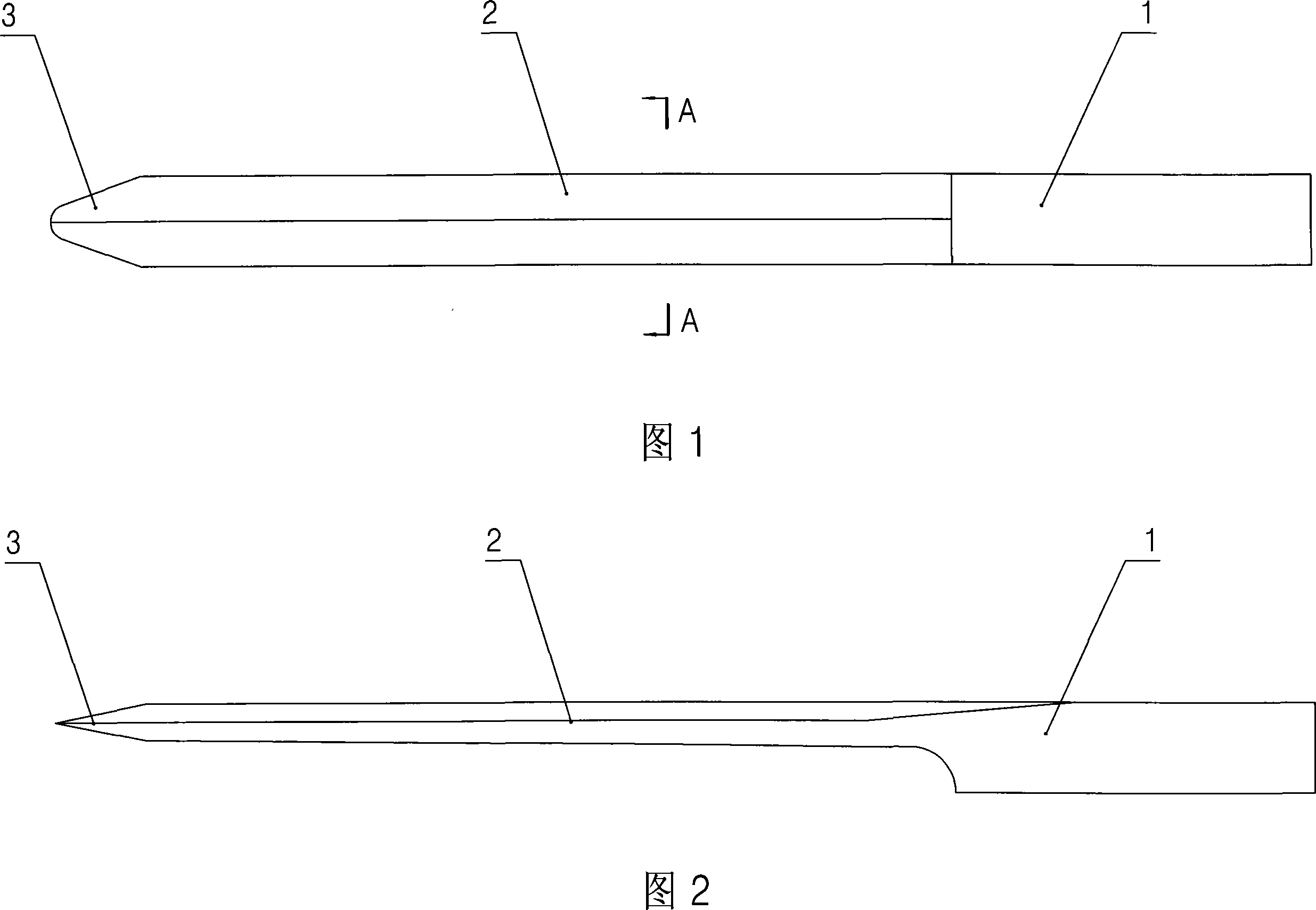

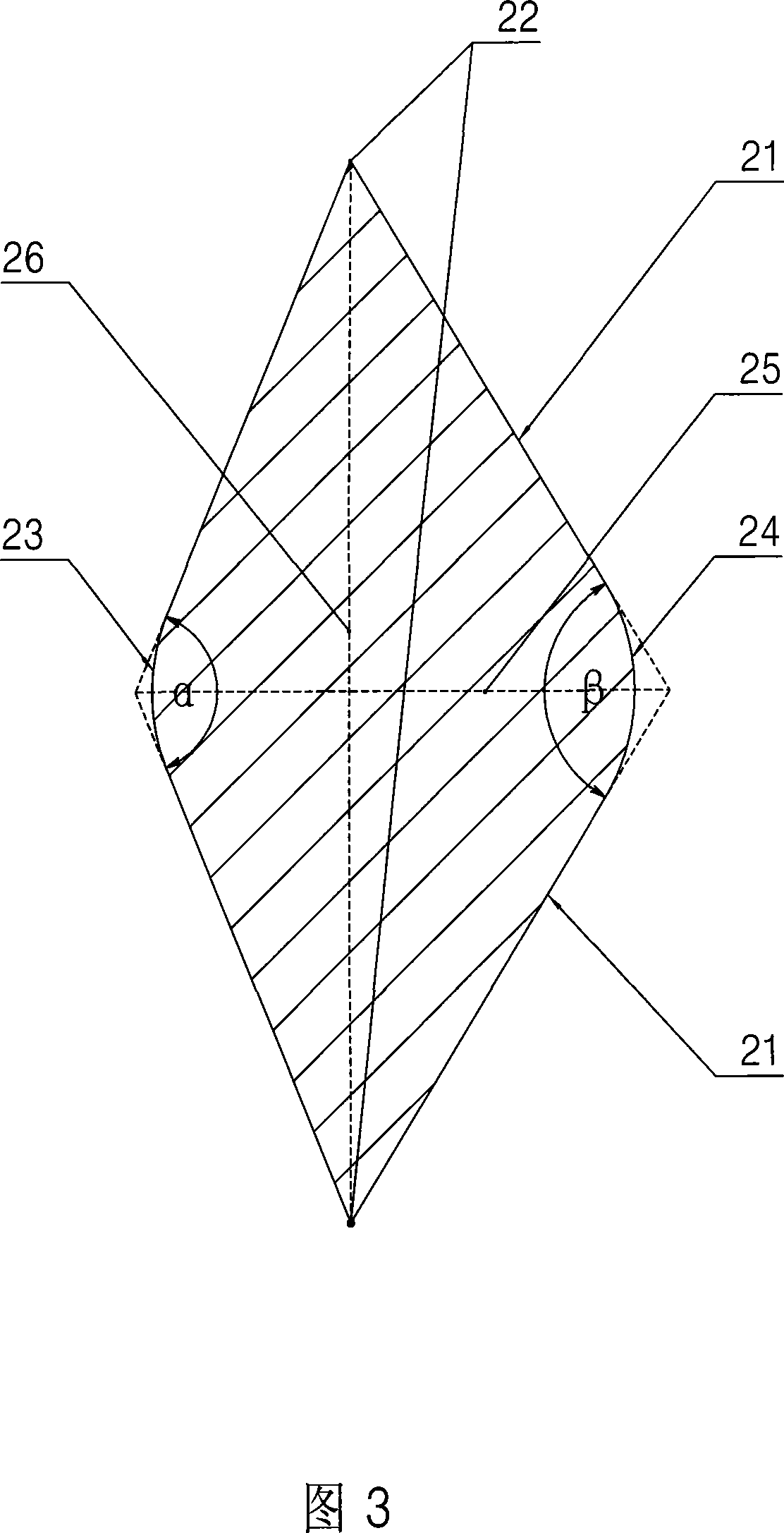

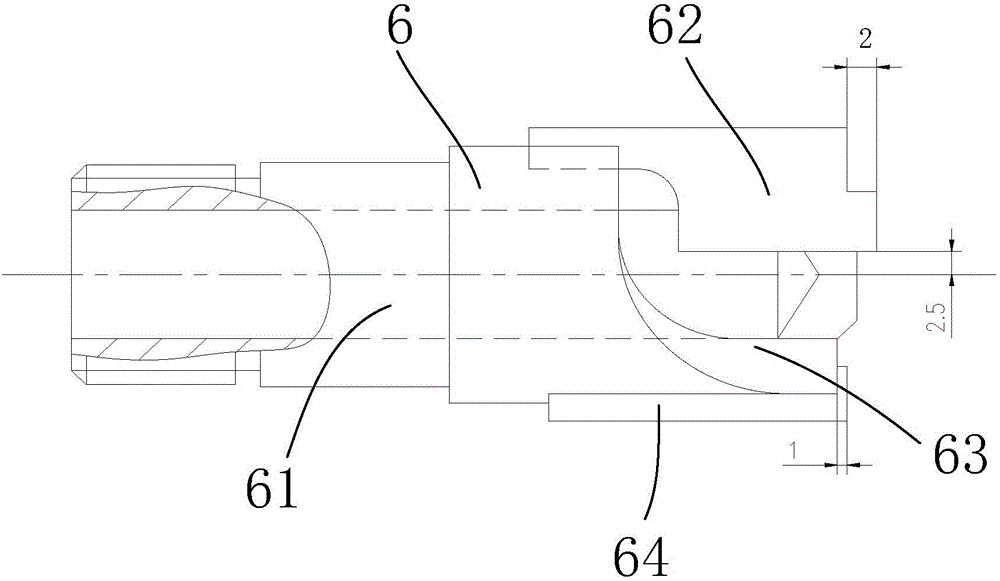

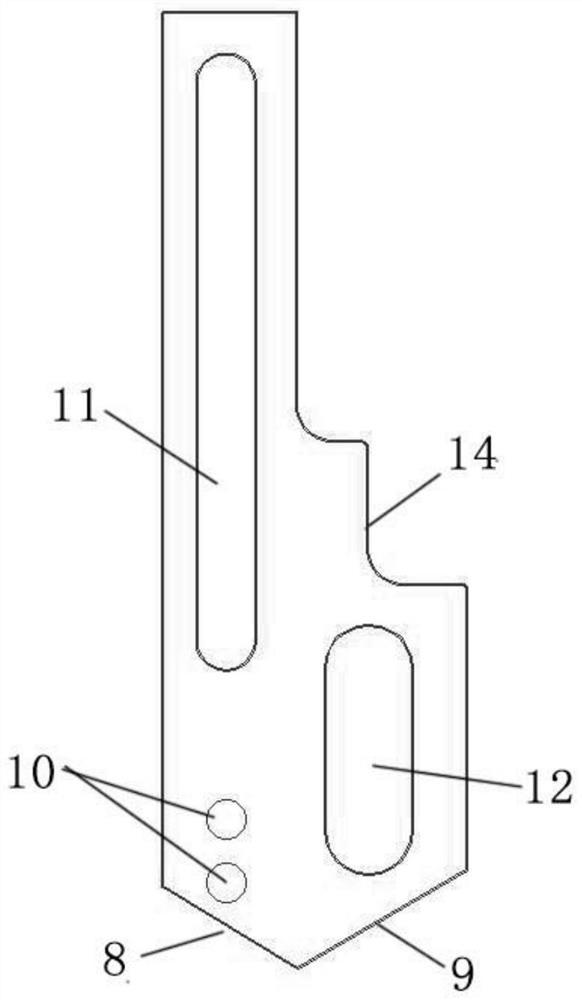

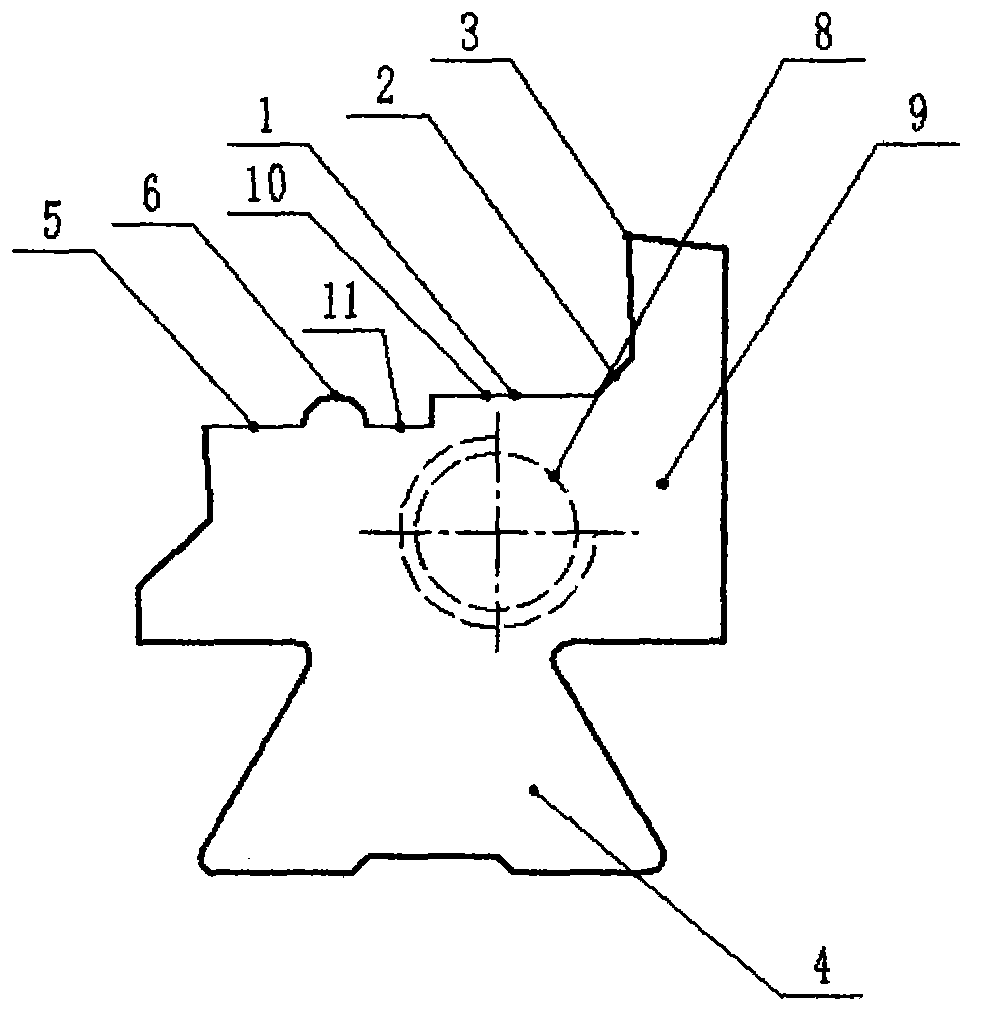

Perforating knife

InactiveCN101157221AComply with the drilling process requirementsEasy to sharpenMetal working apparatusCardboardDiagonal

The invention discloses a perforating cutter, which can adapt the process requirements of perforating on the comparatively soft material such as honeycomb paper board and corrugated board. The invention comprises a cutter handle and a cutter body arranged on the cutter handle, a cutter tip is arranged at the end part of the cutter body, a cross section of the cutter body is a quadrangle with diagonal lines of different lengths, and the cross section is symmetrical along a short diagonal line, inner and outer included angles of the two ends of the short diagonal line of the quadrangle are not equal, the outer included angle is larger than the inner included angle, the two side surfaces forming the inner included angle of the cutter body are the grinding surfaces, and cutter blades are arranged at the two ends of a long diagonal line of the cutter body. The round hole perforated on the comparatively soft material such as honeycomb paper board and corrugated board through the perforating cutter is smooth without rough selvedge, and the invention completely conforms to the perforating process requirements; the two grinding surface are plane surfaces, and the cutter sharpening is very convenient.

Owner:ZHANGJIAGANG DESHUN MACHINERY

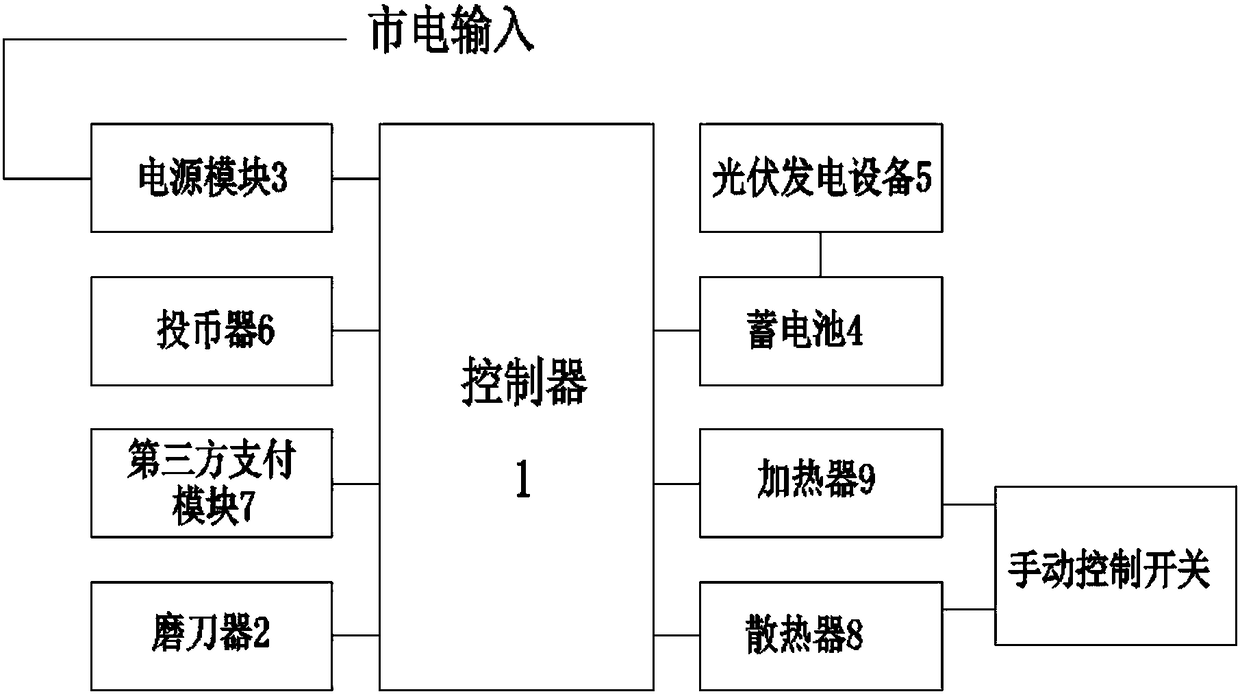

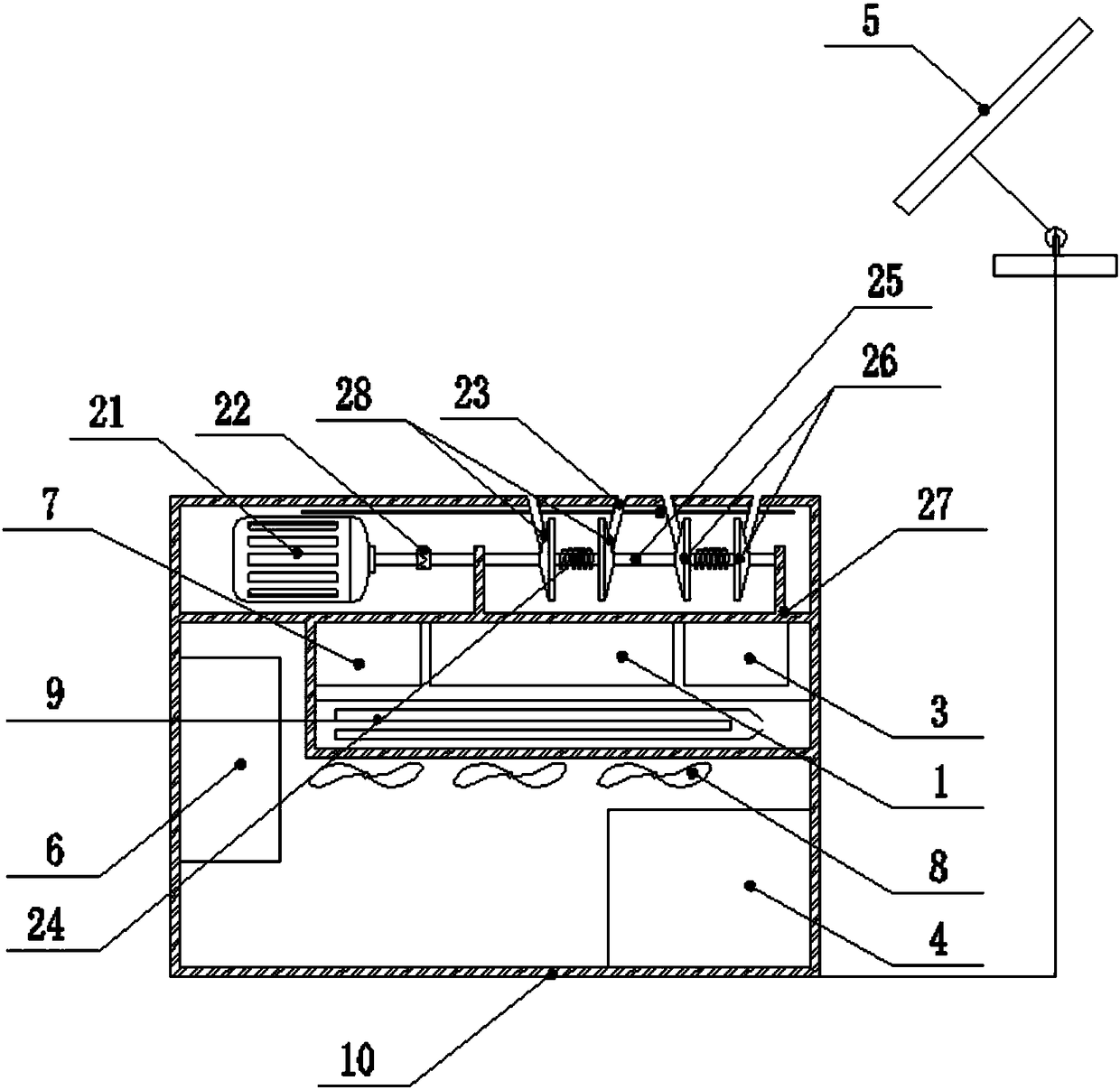

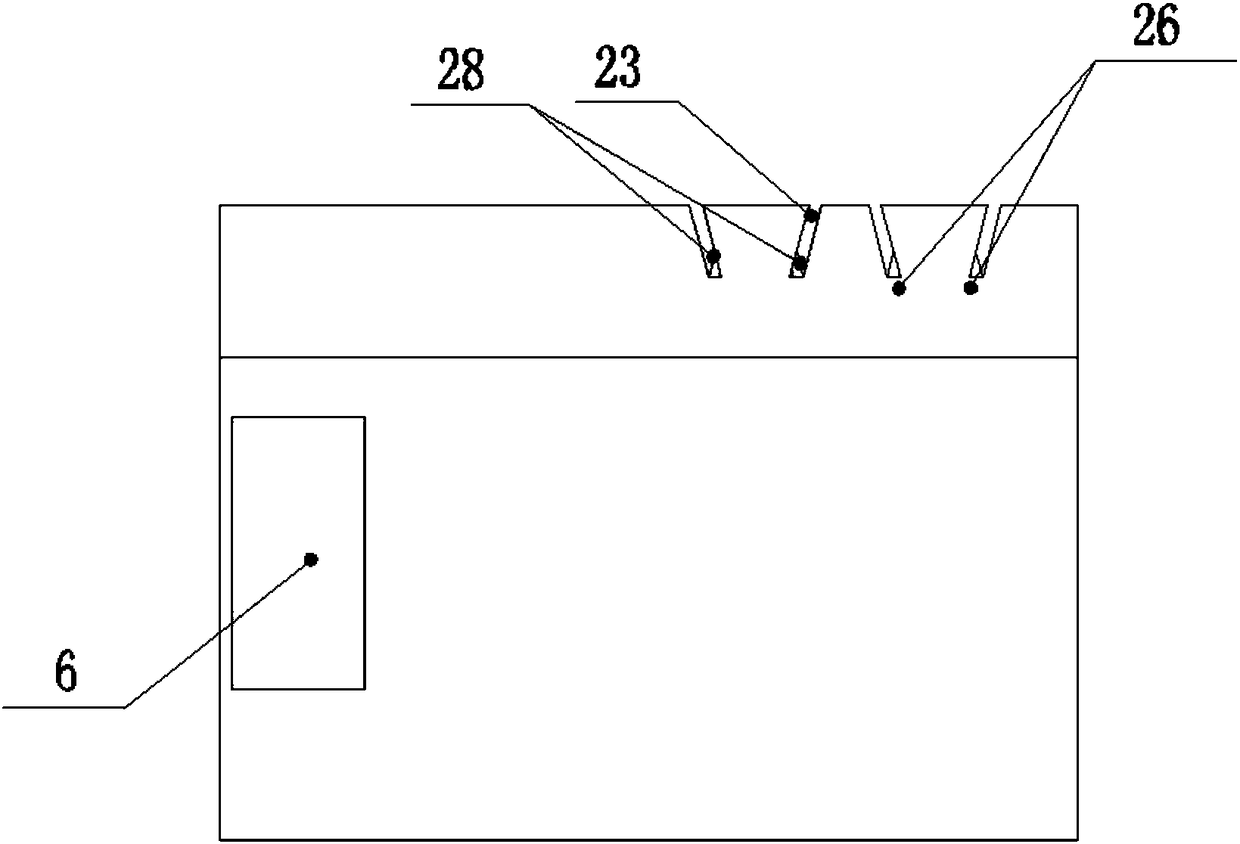

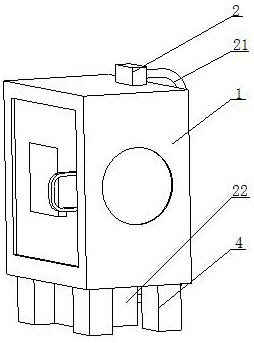

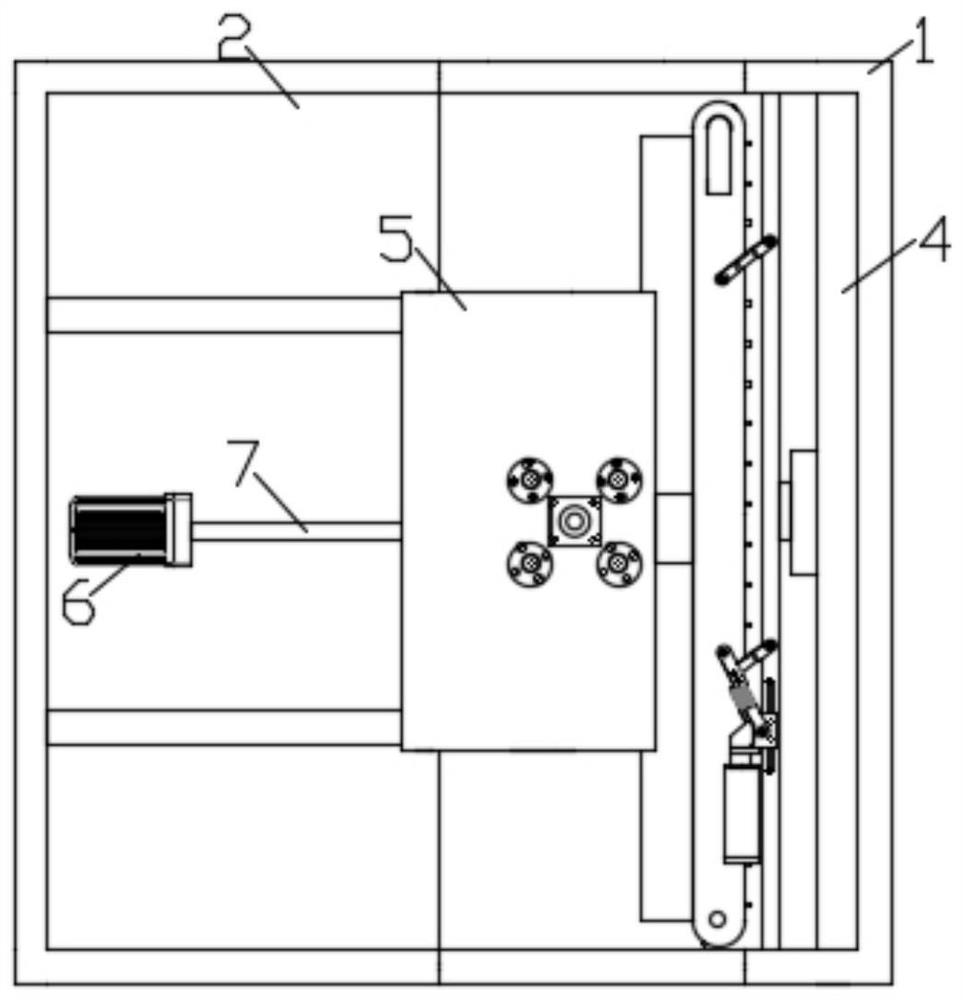

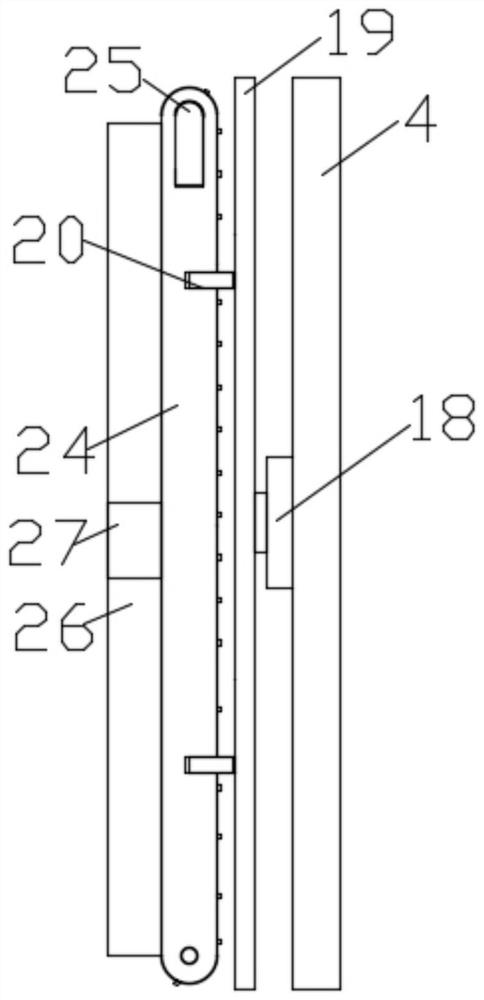

Shared knife sharpener and shared knife sharpening system with same

PendingCN108311964AIncrease usageAvoid wastingApparatus for meter-controlled dispensingOther manufacturing equipments/toolsKnife sharpenerThird-Party Payments

The invention provides a shared knife sharpener and a shared knife sharpening system with the same. The shared knife sharpener comprises a box body, a knife sharpener body, a controller, a coin collector, a third party payment module, a heater, a radiator, a storage battery and a power module, wherein the knife sharpener body, the controller, the coin collector, the third party payment module, theheater, the radiator, the storage battery and the power module are arranged inside the box body. Photovoltaic power generation equipment is further arranged outside the box body. The third party payment module is connected with the input end of the controller. The coin collector is connected with the input end of the controller, and the output end of the controller is connected with the knife sharpener body. The shared knife sharpening system comprises the shared knife sharpener, a server and a mobile phone of a user. One or more shared knife sharpeners are installed in different areas, and each shared knife sharpener is connected with the server. The server is in wireless connection with the mobile phone of the user. According to the shared knife sharpener and the shared knife sharpeningsystem with the same, the photovoltaic power generation equipment and the storage battery are adopted so that electric energy can be saved, operating cost is reduced, the shared knife sharpener can further be installed at regions without power connection conditions, the usage rate of the knife sharpener is increased and wasting of resources is reduced.

Owner:包欣睿

Neodymium iron boron multi-face grinding device

InactiveCN112605825AAvoid scatterEasy to collectGrinding machinesGrinding work supportsHydraulic cylinderPhysical chemistry

The invention relates to the technical field of neodymium iron boron, in particular to a neodymium iron boron multi-face grinding device. The device comprises a body, wherein a water suction pump is arranged at the upper end of the body, a first pipeline is arranged at the right end of the water suction pump, and a water tank is arranged at the lower end of the body. According to the device, through the combined arrangement of a collecting hopper and a draught fan, grinding residues and water flow can be collected, the damage to the interior of the body due to the fact that the residues and the water flow remain in the body is avoided; in addition, through the annular arrangement of the interior of the draught fan, collection of residual liquid can be increased, and the situation that the residual liquid scatters everywhere to cause the adverse effect is avoided; through the arrangement of a water tank and a filter screen, solid substances in the residual liquid can be filtered, the liquid can be reused, and the environment-friendly effect is achieved; through the arrangement of a left semi-circular plate and a right semi-circular plate, workpieces of various sizes can be clamped; and in addition, through the combined arrangement of a hydraulic cylinder, a first lead screw and a second lead screw, the two semi-circular plates can be pushed in an air pressure mode to clamp the workpieces.

Owner:GANZHOU FORTUNE ELECTRONICS

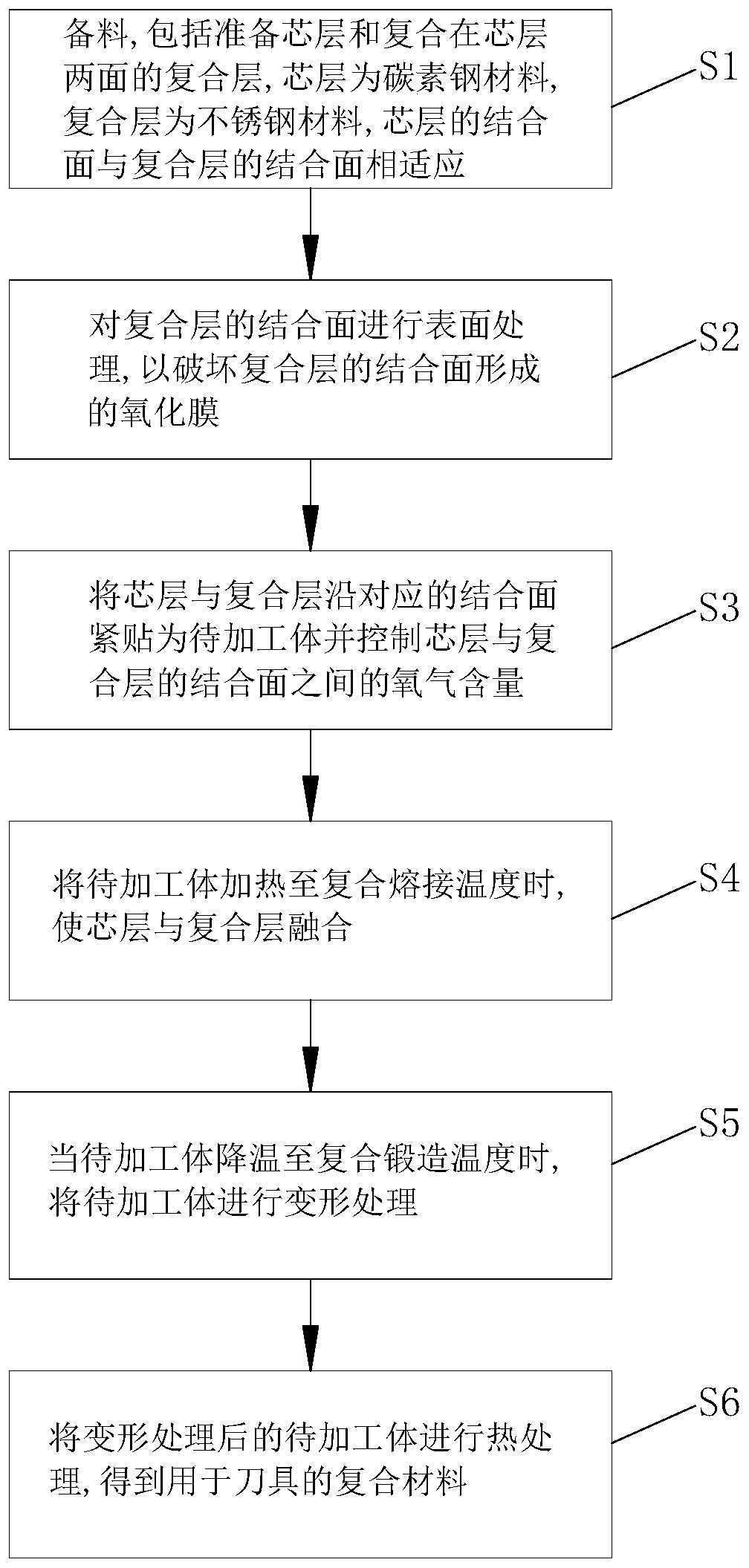

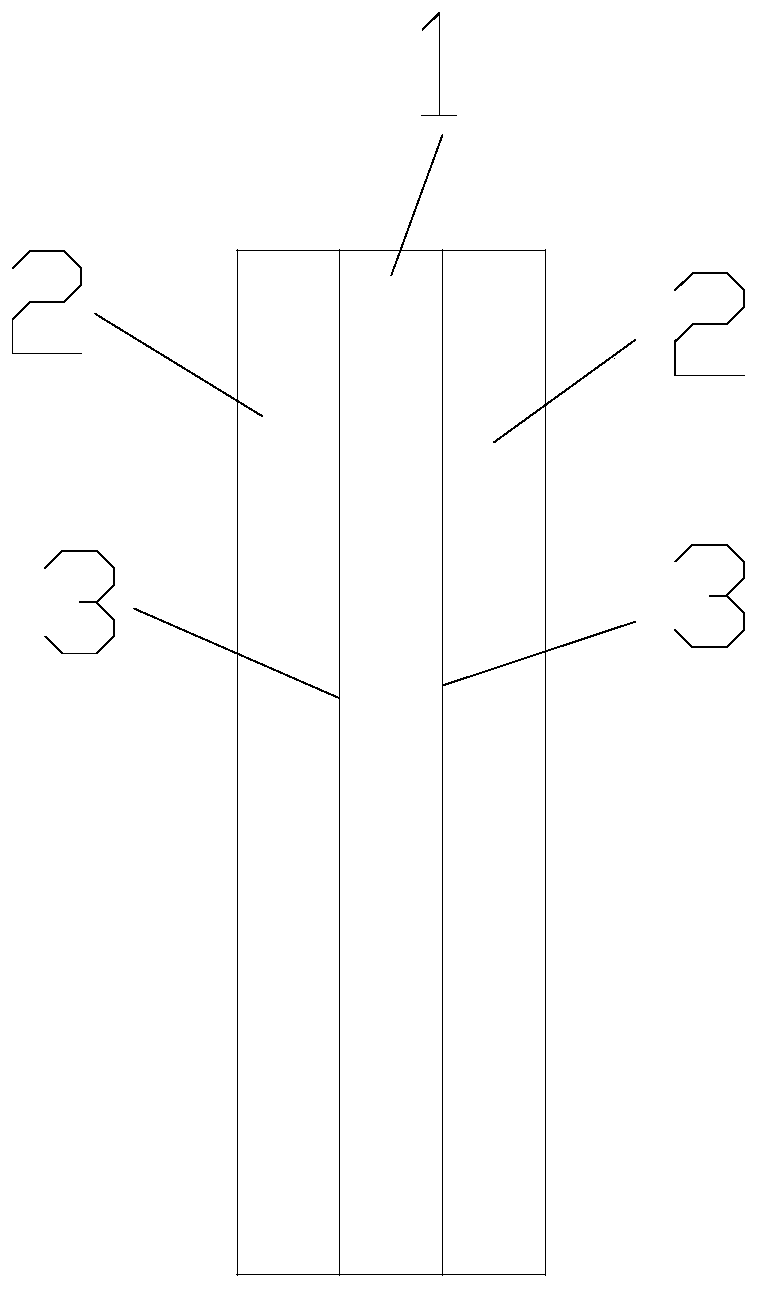

Cutter, composite material thereof and preparation method of composite material

InactiveCN110170605AGood anti-rust functionHigh hardnessMetal rolling arrangementsCutleryMaterials preparationHardness

The invention discloses a cutter, a composite material thereof and a preparation method of the composite material. The preparation method of the composite material includes the steps of material preparation; performing surface treatment on the joint face of a composite layer; tightly closing a core layer to the composite layer and forming a to-be-machined body in a sealing manner; when the to-be-machined body is heated to a composite fusion welding temperature, the surface of the composite layer of the to-be-machined body is slightly knocked; at a composite forging temperature, the to-be-machined body is subjected to deformation treatment; and the to-be-machined body after deformation treatment is subjected to heat treatment. The composite material of the cutter is made according to the preparation method, and the cutter is made according to the composite material. The preparation method solves the problem that combination of stainless steel and plain carbon steel is difficult, the composite material obtained through the preparation method of the composite material has good rust preventing function, large hardness and toughness is achieved, and the cutter made from the composite material has good rust preventing function; and meanwhile, a cutting edge is large in hardness, a cutter body is good in toughness, the cutting edge is not likely to generate a notch and cutting edge curving, re-grinding performance is good, and use by a user is convenient.

Owner:佛山市徐城记厨具有限公司

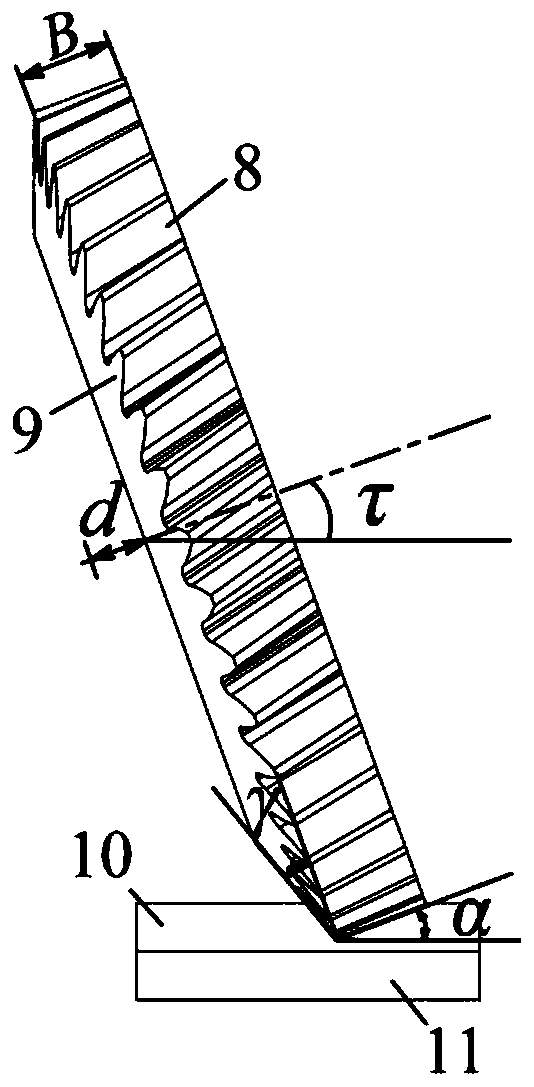

Hard tooth surface gear finish turning process and design method of tooth turning tool of hard tooth surface gear

InactiveCN110465706AImprove processing efficiencyReduce use costGear teeth manufacturing toolsGear teethHardnessConical surface

The invention discloses a hard tooth surface gear finish turning process. The process comprises the steps that 1, a gear workpiece is roughly machined, a tooth turning process is adopted, machining allowance is reserved on the tooth surface of the workpiece, the tooth root of the workpiece is dug, and after rough machining is finished, heat treatment is carried out; 2, finish turning is carried out on the gear workpiece subjected to rough machining, a tooth turning process is adopted, the machining allowance of the tooth surface of the workpiece is cut off by the side edge of the cutter tooth,and the tooth root of the workpiece keeps the surface layer of heat treatment. A design method of a tooth turning tool of a hard tooth surface gear comprises the following steps of 1) the rake angleof the tooth turning tool is designed to be a negative angle, and the rake surface is designed to be a conical surface or a curved surface easy to grind; and 2) according to the flexible adjusting method of the working angle of the cylindrical tooth turning tool, the working angle of the tooth turning tool is made to fall within a preset range which is most suitable for finish machining of hard tooth surface gear workpiece with one certain hardness, and a gear cutting edge curve is calculated. Hard tooth surface gear machining efficiency is high, the using cost is low, gear transmission and noise reduction are facilitated, and the tool service life is long.

Owner:XIAN UNIV OF TECH

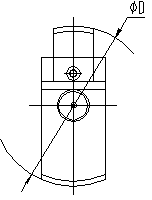

Novel sphere cutter blade grinding device

InactiveCN103419098AEasy to sharpenFast sharpeningOther manufacturing equipments/toolsEngineeringMechanical engineering

A sphere cutter blade grinding device comprises a center and a clamp body, wherein two center holes are formed in the left end and the right end of the clamp body respectively, a sphere cutter installation groove and a cutter fixing mechanism are arranged at the upper end of the clamp, and a movable cushion block is installed at the bottom of the sphere cutter installation groove. The novel sphere cutter blade grinding device can grind various sphere cutter blade arcs conveniently, rapidly and accurately, reduce equipment investment, and meet the production requirement.

Owner:GUIZHOU AEROSPACE HONGGUANG MACHINERY MFG

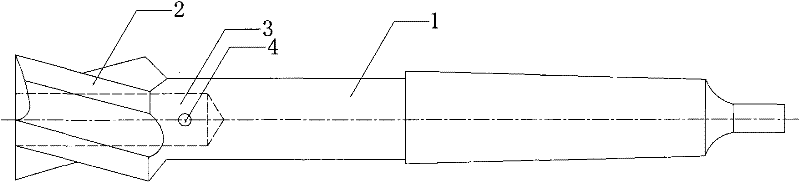

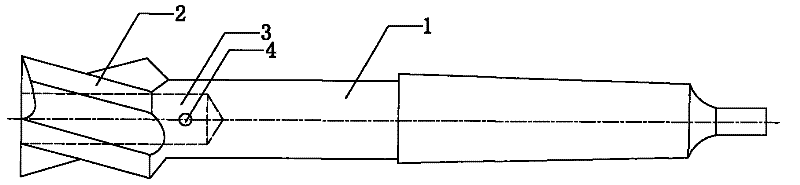

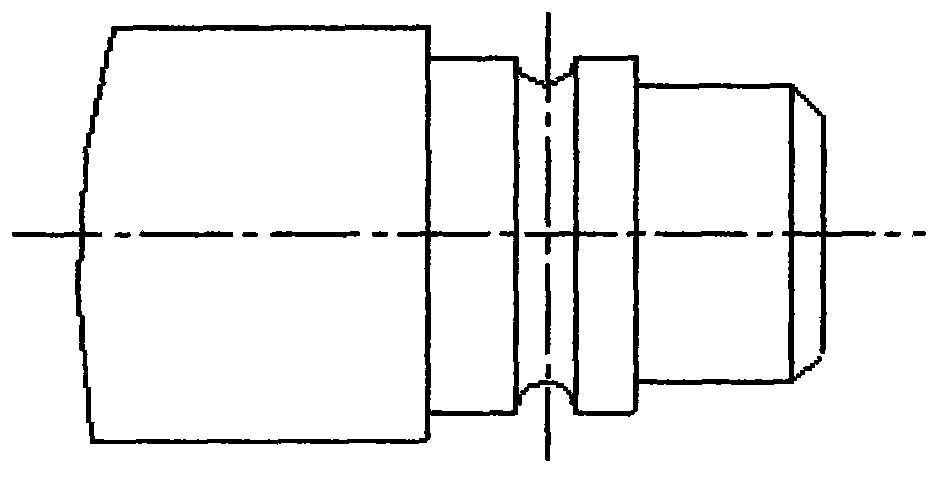

Drilling reamer

InactiveCN102407365AEasy to sharpenEasy to fixTransportation and packagingTrepanning drillsTool bitReamer

The invention relates to a drilling reamer comprising a tool holder and a tool bit, wherein the tool bit is arranged on one end of the tool holder, and the horizontal center line of the tool bit is overlapped with that of the tool holder. The drilling reamer is characterized in that the tool bit is provided with a threaded hole along the horizontal center line, and the threaded hole is led to the inside of the tool holder. The drilling reamer is wide in application range and convenient to sharpen, and a drill bit is replaceable.

Owner:张灵娟

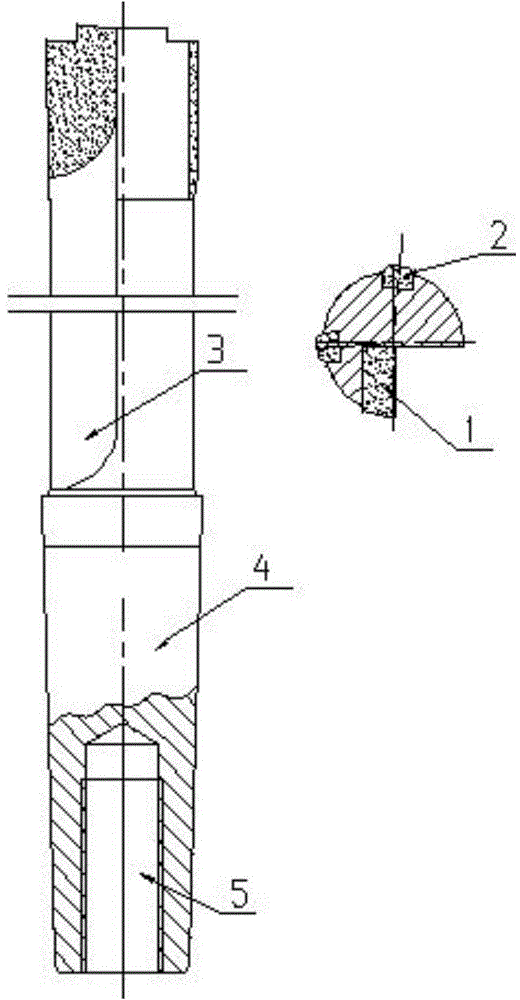

Deep hole boring cutter

InactiveCN104400034AReduce weightWeight optimizationCutting insertsTurning toolsEngineeringDeep hole

The invention provides a deep hole boring cutter. The deep hole boring cutter comprises a cutter body and a cutter rod; a chip hole is formed in the center of the cutter body; the cutter rod is of a hollow structure and is in threaded connection with the rear end of the cutter body; a cutting blade is arranged at the front end of the cutter body; a chip groove is formed in the cutter body part at one side of the cutting blade, and the chip groove is communicated with the chip hole. According to the deep hole boring cutter, a working part is an independent part according to the design, namely, an individual cutter body, and therefore, the weight of the cutter body can be greatly reduced, and an edge can be conveniently grinded; the external chip removal structure is replaced by an internal chip removal structure according to the design, which prevents the chips and cooling liquid produced in processing from splashing all around; the threaded connecting structure enables convenient dismounting and mounting of the cutter body, and thus the cutter can be conveniently grinded and adjusted during use; the hollow cutter rod is used, so that the weight of the whole cutter is reduced, and an hole in the cutter rod can be fully utilized for removing chips; the processing procedure can be modified to control the feeding length of the cutter rod to be adapted to the processing of different deep holes.

Owner:CHONGQING YAOYONG SHOCK ABSORBER

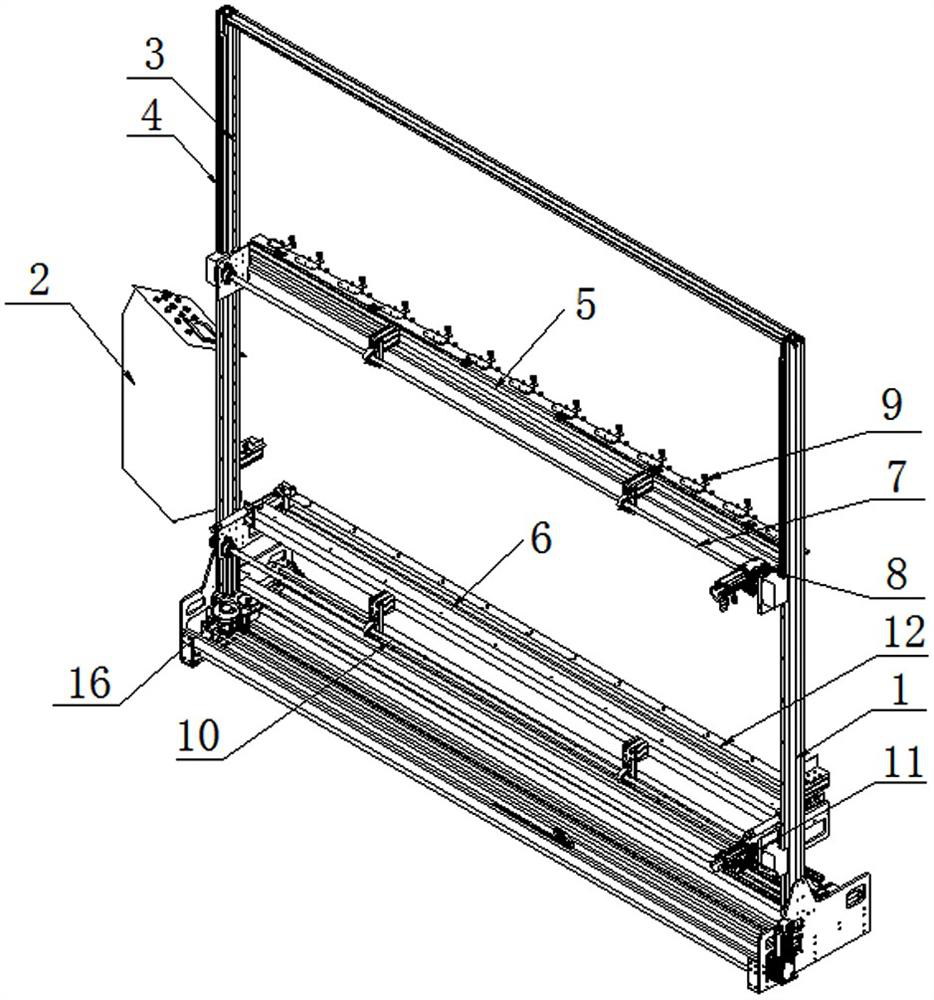

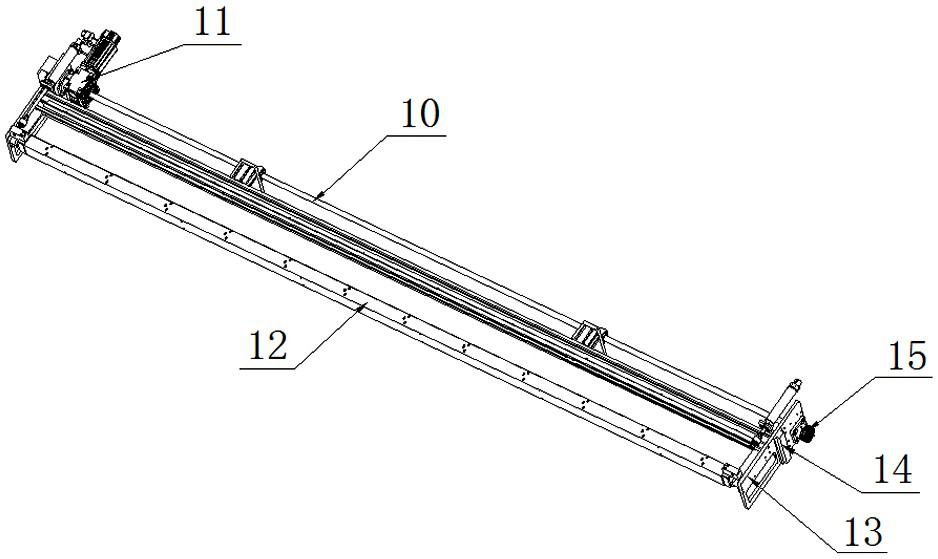

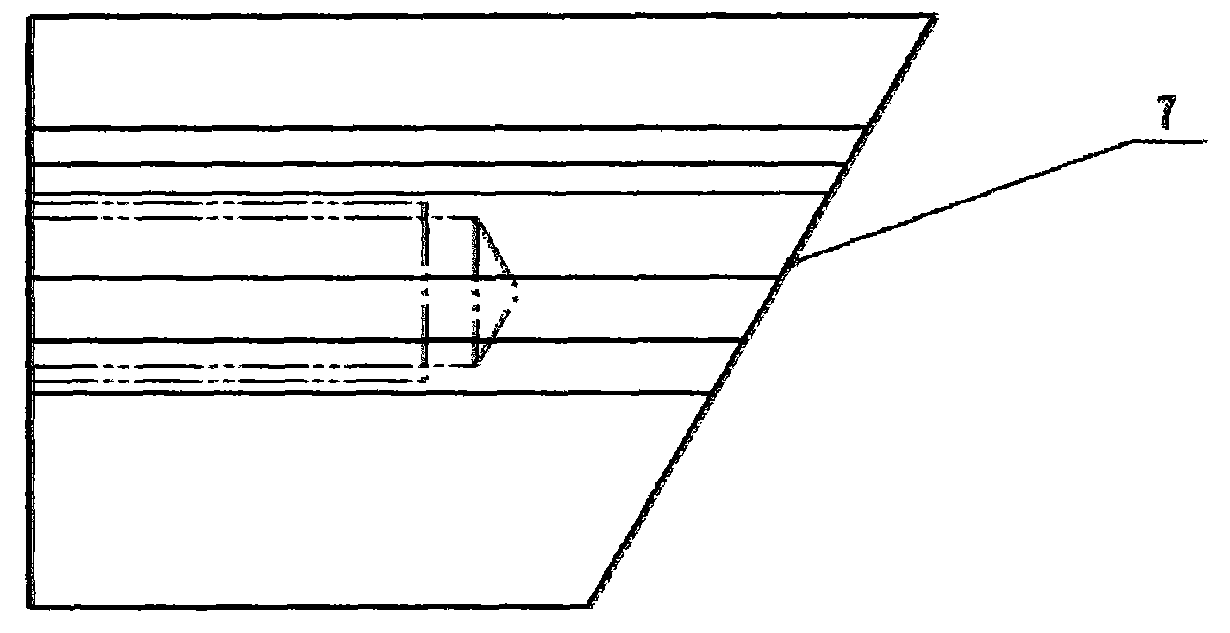

Curtain height cutting device

InactiveCN112482003AImprove flatnessNeat cutSevering textilesOther manufacturing equipments/toolsGear wheelElectric machinery

The invention discloses a curtain height cutting device. The curtain height cutting device comprises a stand column and a control cabinet; guide rails are arranged in the opposite faces of the two inner sides of the stand column respectively; racks are arranged on the two outer side faces of the stand column respectively; a primary lifting assembly and a secondary lifting assembly are arranged onthe stand column; the primary lifting assembly and the secondary lifting assembly each comprise a mounting plate, a servo motor, a shaft, a sliding block I, a gear and a pneumatic clamp; the two endsof each shaft are connected with the gears; the gears are matched with the corresponding racks; the sliding blocks I are matched with the corresponding guide rails; a flying disc type cutter device isarranged at the bottom of the stand column and comprises a support, a cutter assembly and a flying disc motor; and the flying disc motor is in linkage work with the cutter assembly through a synchronous belt and a synchronous wheel. The tailoring height can reach 5-6 m, the tailored cloth is good in flatness, tailored openings are tidy, operation is easy, labor is saved, scribing and positioningcan be conducted, and the overall occupied space is small.

Owner:浙江蓝凌电子科技有限公司

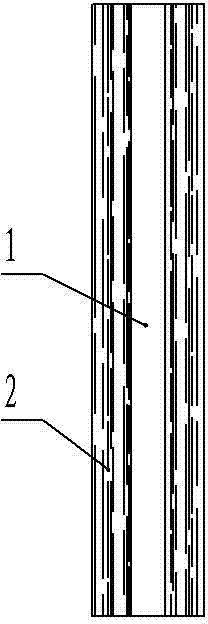

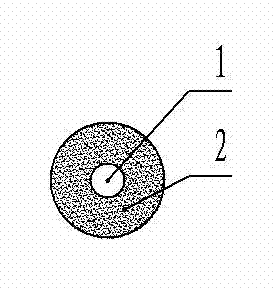

Wood rolled pencil and making method thereof

The invention discloses a wood rolled pencil which relates to the technical field of stationery. The wood rolled pencil consists of a pencil core and a pencil holder which is wrappeding outside the pencil core and rolled by sheet materials. The wood rolled pencil is characterized in that a wood sheet is used as the pencil holder material, and the fiber textures of the wood sheet are parallel with the axial direction of the pencil core. Compared with the prior art, the wood rolled pencil has the advantages of wide material acquisition range, freedom from limitation of wood types and high wood utilization rate. The invention also discloses a making method for the wood rolled pencil.

Owner:广东润炜文具有限公司

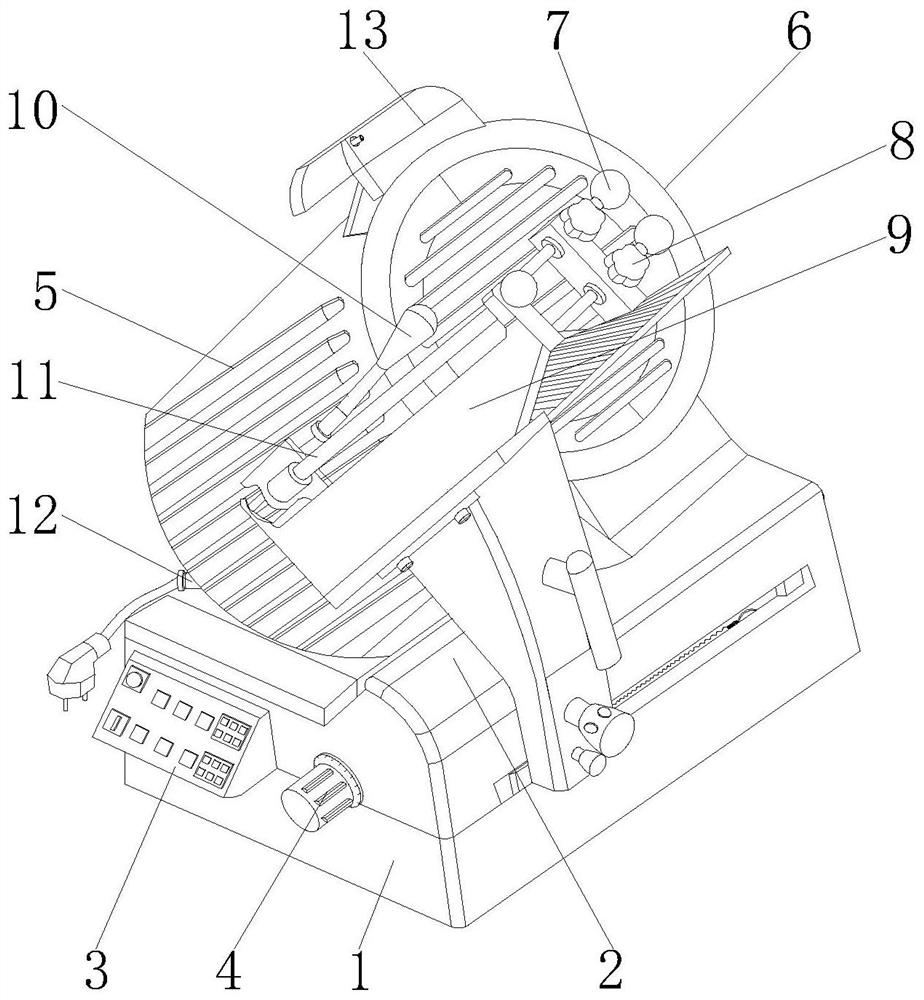

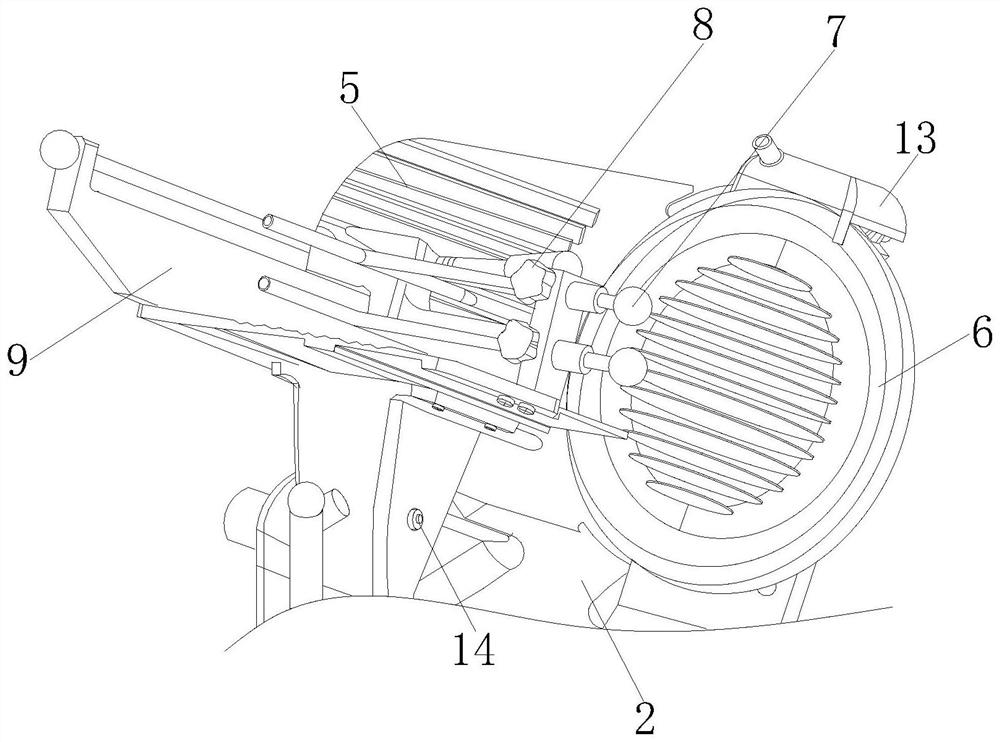

Full-automatic slicer

PendingCN112536834AImprove slicing efficiencySave time and energyMetal working apparatusEngine lubricationHandrailHand parts

The invention provides a full-automatic slicer. The full-automatic slicer comprises a base, wherein a slicer body is bolted to the top of the base; an operation panel is bolted to the left side of thefront surface of the base; a manual regulator is rotationally connected to the right side of the front surface of the base; material baffles are bolted to the periphery of the slicer body; a cutter protection ring is annularly bolted to the top of the right side of the slicer body; handrails are bolted to the periphery of the top of the right side of the slicer body; and a locking handle is bolted to one side, away from the cutter protection ring, of each handrail. Through the cooperation of a nail plate sliding shaft, the material baffles, a material pressing nail plate, a nail plate heavy block, the locking handles and the handrails, boneless meat, ham products, bread, melons and fruits and other food can be quickly sliced, manual meat slicing work of a user is replaced, the food slicing efficiency is improved, the time and energy of the user are saved, meanwhile, the labor intensity of the user is reduced, and a hand of the user is prevented from being cut accidentally.

Owner:GUANGDONG MINGSHIDA ELECTRICAL APPLIANCE CO LTD

Writing case provided with pencil sharpener

The invention discloses a writing case provided with a pencil sharpener. The writing case comprises a writing case unit, and is characterized in that the pencil sharpener is arranged on the writing case unit. The pencil sharpener is arranged on the writing case unit, so that in study, the pencil sharpener can be used for sharpening pencils in need conveniently by students, purchase of another pencil sharpener is not necessary, no extra space is occupied, and invention purpose of the invention is achieved.

Owner:GUCHENG COUNTY THIRD MIDDLE SCHOOL

Method for machining side punch through hole of mold punching device

The invention discloses a method for machining a side punch through hole of a mold punching device, which comprises the following steps: 1, when sheets are not fed, adhering the lower bottom surface of a punching device to the upper surface of a lower mold, and determining a through hole positioning circle for the idle motion of a side punch through hole on the side wall of the punching device according to a side punch hole corresponding to the lower mold; 2, when the sheets are fed, determining a through hole positioning circle for the punching motion of the side punch through hole on the side wall of the punching device according to the side punch hole corresponding to the lower mold; 3, drawing an enveloping circle enveloping the through hole positioning circle for the idle motion and the through hole positioning circle for the punching motion on the side wall of the punching device; and 4, drilling the side punch through hole along the enveloping circle, wherein the diameter of the side punch through hole is greater than that of the enveloping circle. In the method, on the premise of ensuring the punching function of the mold, a milling process method which must be used originally is changed into a drilling method, and the advantages such as multiple sizes of drill bits, high cutting efficiency and convenient sharpening process are fully taken, thereby achieving the purpose of enhancing the machining efficiency and reducing the cost.

Owner:SHANDONG WEIFANG FOTON MOLD

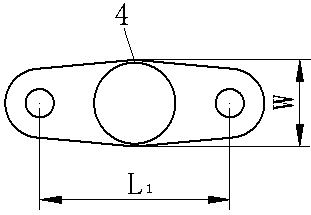

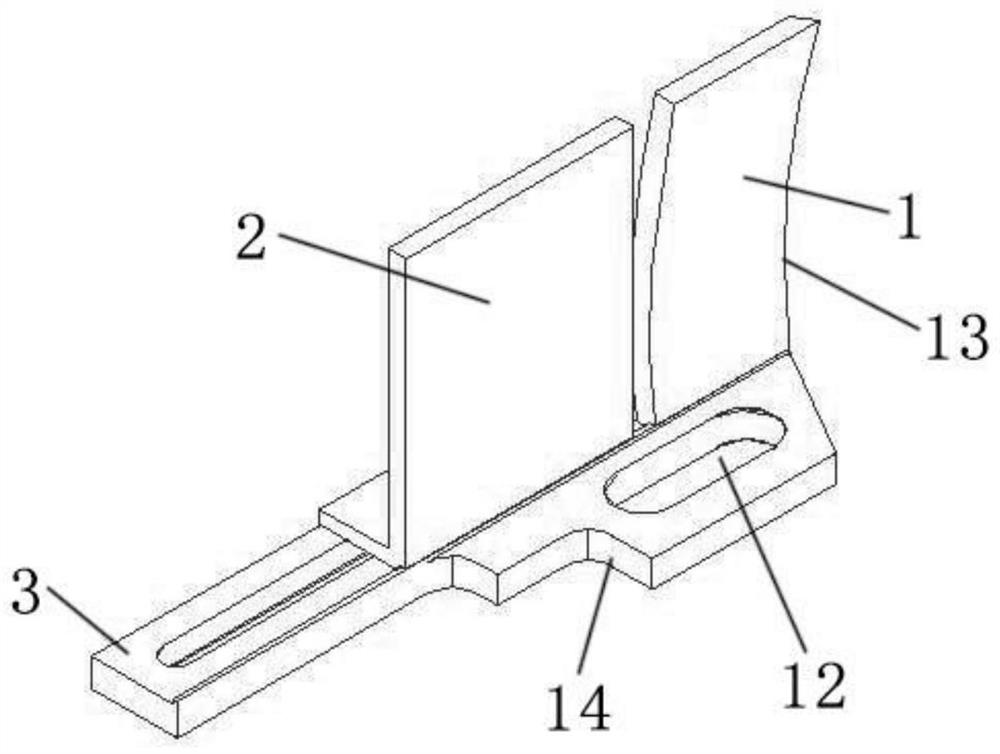

Cutter sharpening rack

ActiveCN105538053AEasy to sharpenWon't scratchGrinding carriagesOther manufacturing equipments/toolsSharpeningEngineering

The invention discloses a cutter sharpening rack. The cutter sharpening rack comprises a bottom plate, a sliding plate which is detachably connected onto the bottom plate and a cutter sharpening block which is fixedly connected onto the sliding plate; multiple cutter sharpening grooves are formed in the cutter sharpening block; the cutter sharpening grooves are separately divided into first section grooves and second section grooves from the outer part to the inner part along the cutter sharpening block; and the groove opening widths of the first section grooves are larger than the groove opening widths of the second section grooves. According to the cutter sharpening rack, the hand of an operator cannot be scratched during a cutter sharpening process; and the operator can sharpen a cutter conveniently.

Owner:盐城项果科技有限公司

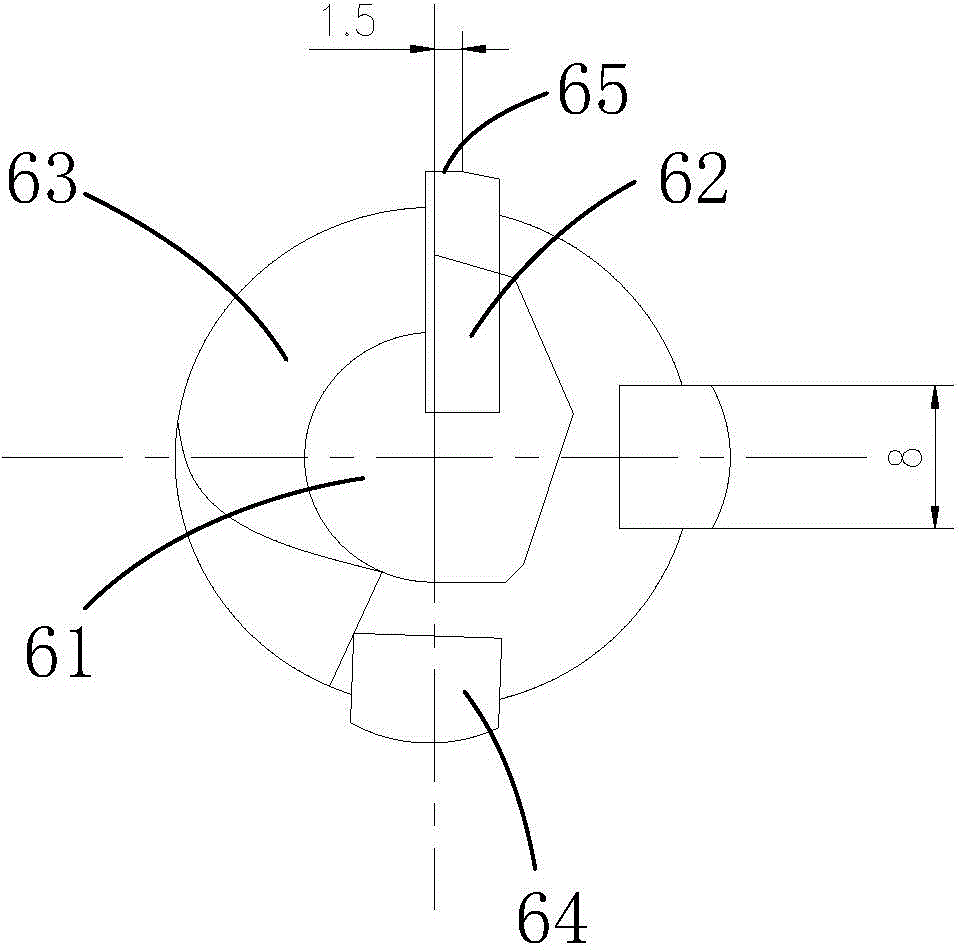

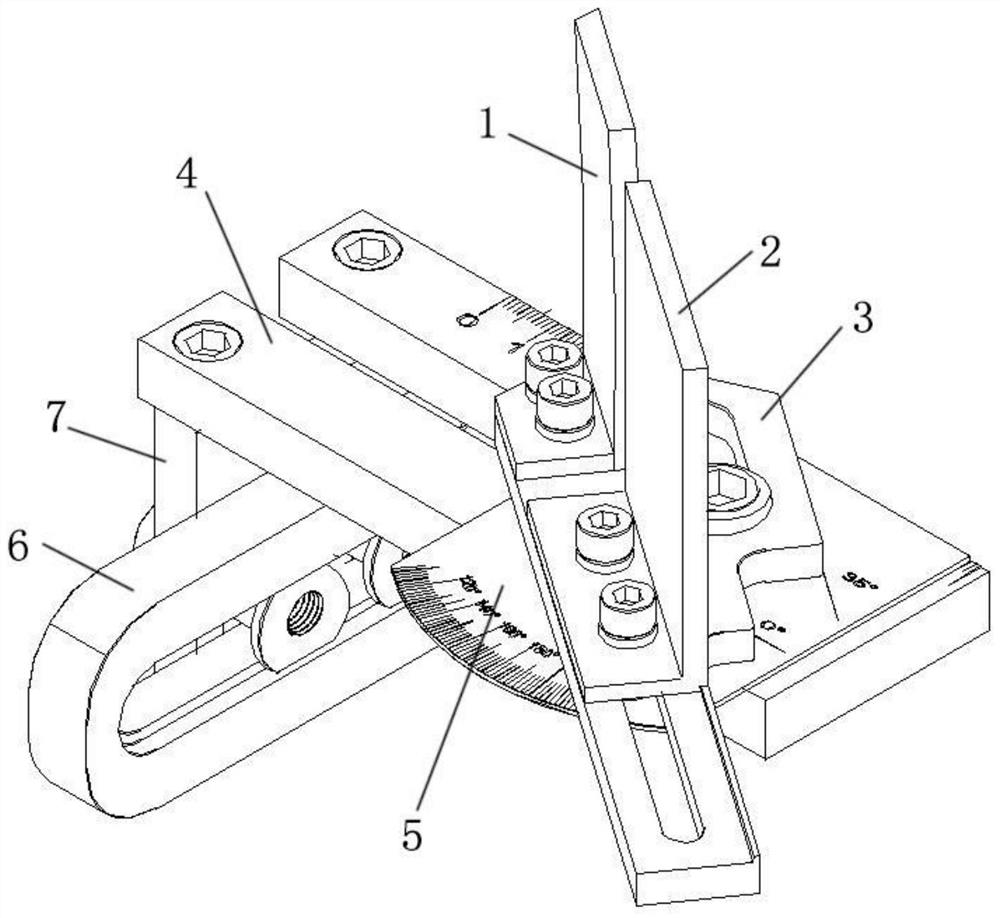

Drill bit edge grinding assembly

PendingCN113070744AAccurate measurementAchieve circular rotationGrinding feed controlDrilling toolsMeasurement deviceEngineering

The invention discloses a drill bit edge grinding assembly. The drill bit edge grinding assembly comprises an edge grinding device and a measuring device, and the edge grinding device and the measuring device are used in cooperation. The edge grinding device comprises a connecting mechanism, a scale positioning mechanism and an auxiliary edge grinding mechanism, one end of the connecting mechanism is connected with the scale positioning mechanism, the auxiliary edge grinding mechanism is arranged on the scale positioning mechanism, and the scale positioning mechanism is used for adjusting the circumferential angle or the axial position of the auxiliary edge grinding mechanism. The auxiliary edge grinding mechanism comprises a first edge grinding piece, a second edge grinding piece and an auxiliary piece, and the first edge grinding piece and the second edge grinding piece are arranged on the auxiliary piece. The drill bit edge grinding assembly has the beneficial effects that by aiming at the difficulty of manual edge grinding, the design concept that the edge grinding device and the measuring device supplement each other is adopted, edge grinding is more accurate and more efficient, personal experience accumulation is not needed, a green hand can grind a sharp and qualified drill bit, and the measuring precision is higher.

Owner:吴祥谦

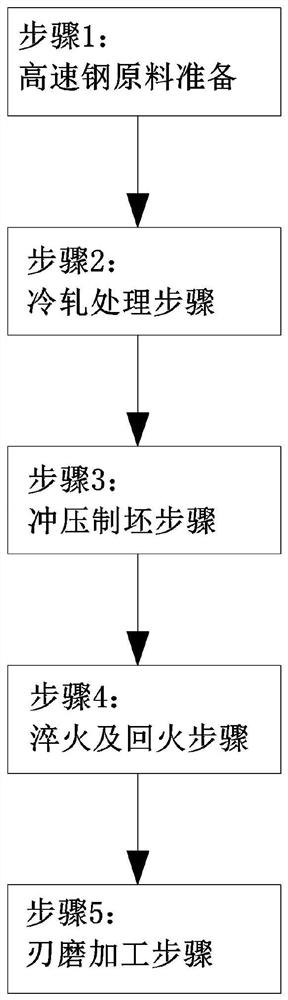

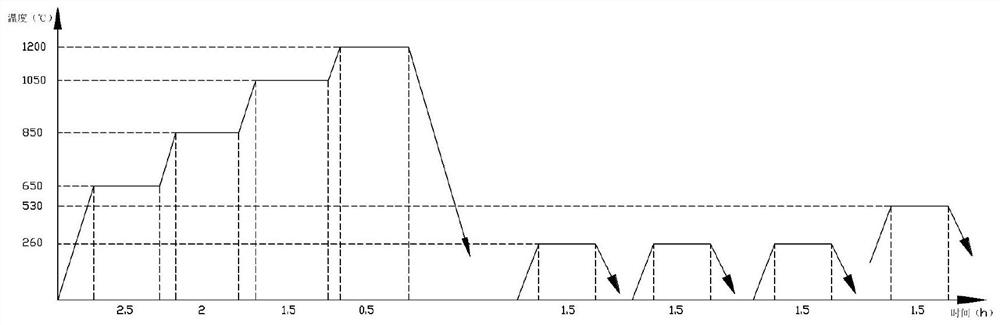

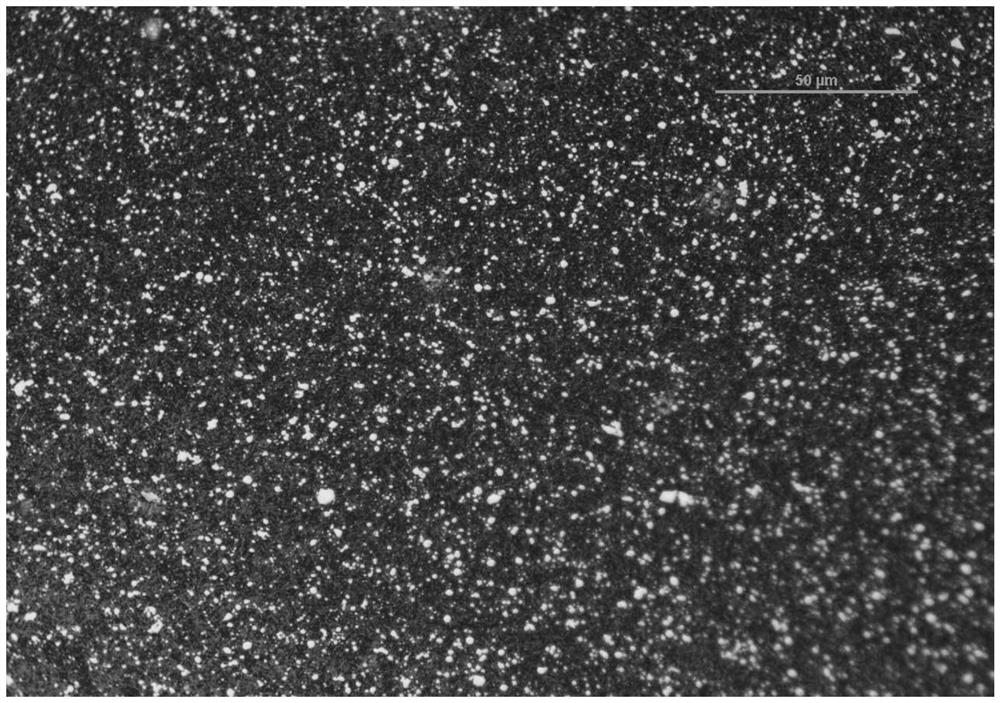

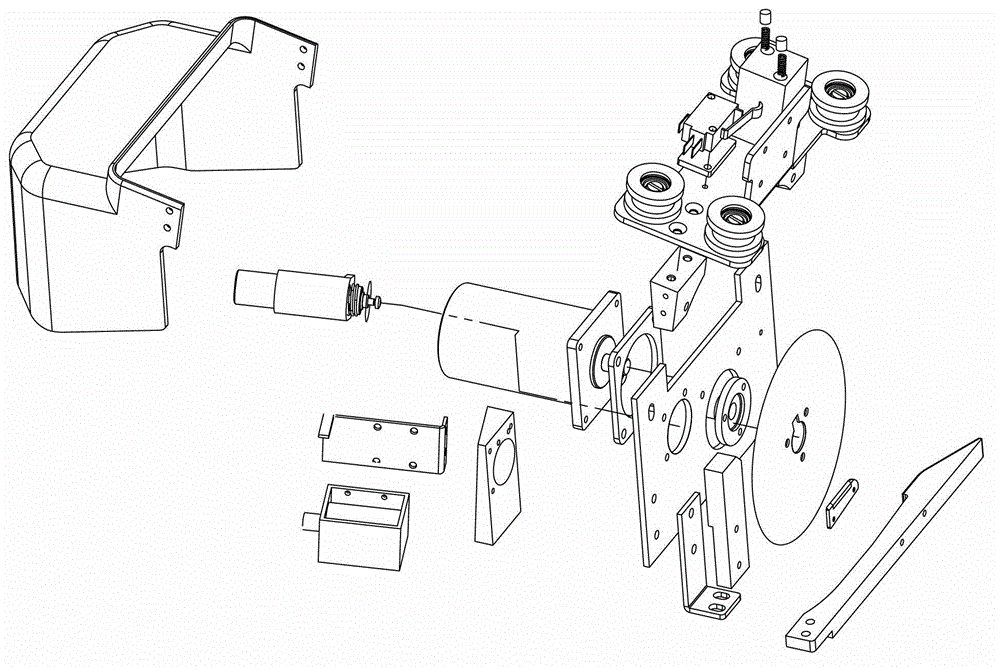

Machining process for high-speed steel surface-replaceable blade

InactiveCN112171216AEasy to sharpenReduced edge strengthFurnace typesHeat treatment furnacesCemented carbideSteel plates

The invention relates to the field of blade machining, and particularly discloses a machining process for a high-speed steel surface-replaceable blade. The machining process comprises a high-speed steel plate raw material preparing step; a cold rolling treatment step; a punching blank making step; a vacuum quenching and tempering treatment step; and an edge grinding machining step, and thus the blade finished product is formed. According to the technical scheme, after the quenching treatment and tempering treatment in the step 4 are carried out, the hardness of the refined blade made of high-speed steel is 63-70 HRC and is smaller than that of a blade made of a conventional hard alloy material, then edging of the refined blade is easier and more convenient during edge grinding machining, thus the edging strength of the refined blade can be effectively reduced, and the machining cost is reduced.

Owner:重庆派斯克刀具制造股份有限公司

Cloth cutting device

The invention provides a cloth cutting device which comprises a fixed assembly, a cutter assembly, a cutter sharpening assembly and a cutter pressing assembly. The fixed assembly is fixedly arranged on a cloth feeding device; the cuter assembly is fixedly arranged on the fixed assembly and comprises a cutter for cutting cloth; the cutter sharpening assembly comprises a grinding wheel for polishing the cutter and is provided with an elongated slot; the cutter sharpening assembly is adjustably connected to the fixed assembly by the elongated slot; the cutter pressing assembly is used for pressing against the cutter and is provided with a plurality of first waist holes; the cutter pressing assembly is adjustably connected to the fixed assembly by the first waist holes. The cloth cutting device provided by the invention has a simple structure; positions of the cutter sharpening assembly and the cutter pressing assembly of the cloth cutting device are convenient to regulate; the cloth cutting device is more beneficial to installation; moreover, the cutter sharpening and cloth cutting operations can be carried out better.

Owner:SHAGNHAI YIN SCI&TECH CO LTD

Slot turning forming turning tool for motor shaft

A slot turning forming turning tool for a motor shaft is a dedicated turning tool for lathe motor shaft. The turning tool is of a prism structure and comprises a turning tool handle part, a turning tool body part and a turning tool edge part. The turning tool handle part is of a swallow tail structure, the lower portion of the turning tool body part is provided with a bolt hole, the turning tool part of the turning tool is used for machining all machining parts of a machined workpiece. By the adoption of the forming turning tool, production efficiency is high, all parts, to be machined, of a workpiece are machined at a time, production efficiency is greatly improved compared with that of traditional production labor intensity of workers is lessened and production cost of a factory is saved.

Owner:芜湖杰诺瑞汽车电器系统有限公司

Hand Pencil Sharpener

The invention relates to a hand-cranking type pencil sharpener. The hand-cranking type pencil sharpener comprises a pencil fixing module for fixing a pencil to the preset position, a pencil sharpening module for sharpening the pencil, a power module for providing power for the hand-cranking type pencil sharpener and a shell for supporting the hand-cranking type pencil sharpener; the pencil fixing module and the power module are oppositely arranged on the two sides of the shell, and the pencil sharpening module is located inside the shell; and one end of the pencil sharpening module is connected with the pencil fixing module, and the other end of the pencil sharpening module is connected with the power module. The hand-cranking type pencil sharpener is energy-saving, environment-friendly and convenient to carry; and compared with a traditional hand-cranking type pencil sharpener, the hand-cranking type pencil sharpener has the beneficial effects that the service life is long, a core is not prone to being broken, and more labor is saved.

Owner:UNIV FOR SCI & TECH ZHENGZHOU

Production process of high-toughness ceramic cutting tool

ActiveCN113087529AImprove toughnessImprove thermal shock resistanceGrinding drivesOther manufacturing equipments/toolsAluminium hydroxideTitanium nitride

The invention discloses a production process of a high-toughness ceramic cutter. By adding nano silicon carbide, nano titanium nitride, modified sepiolite powder, zirconium oxide whiskers and aluminum hydroxide coated calcium fluoride, the toughness, thermal shock resistance and bending strength of the produced ceramic cutting tool are effectively improved. According to GB / T4741-1999 measurement, the bending strength of the high-toughness ceramic cutting tool is 1000 to 1500 MPa. Meanwhile, the invention discloses machining equipment, and the machining equipment can polish one face of the ceramic cutter and clean the other face of the ceramic cutter at the same time. Water is sprayed on the surface of the abrasive belt while the grinding surface is ground, so that chippings can be prevented from splashing while overheating during grinding is prevented; whereas the cleaning of the other side is that sewage generated in the polishing process is recycled and sprayed on the surface of the ceramic cutting tool through filtration and atomization.

Owner:湖南泰鑫瓷业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com