Cutter, composite material thereof and preparation method of composite material

A technology of composite materials and knives, applied in knives, kitchen utensils, household utensils, etc., can solve the problems of difficult combination of stainless steel and carbon steel, and achieve excellent anti-rust function, fusion stability, and good regrinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

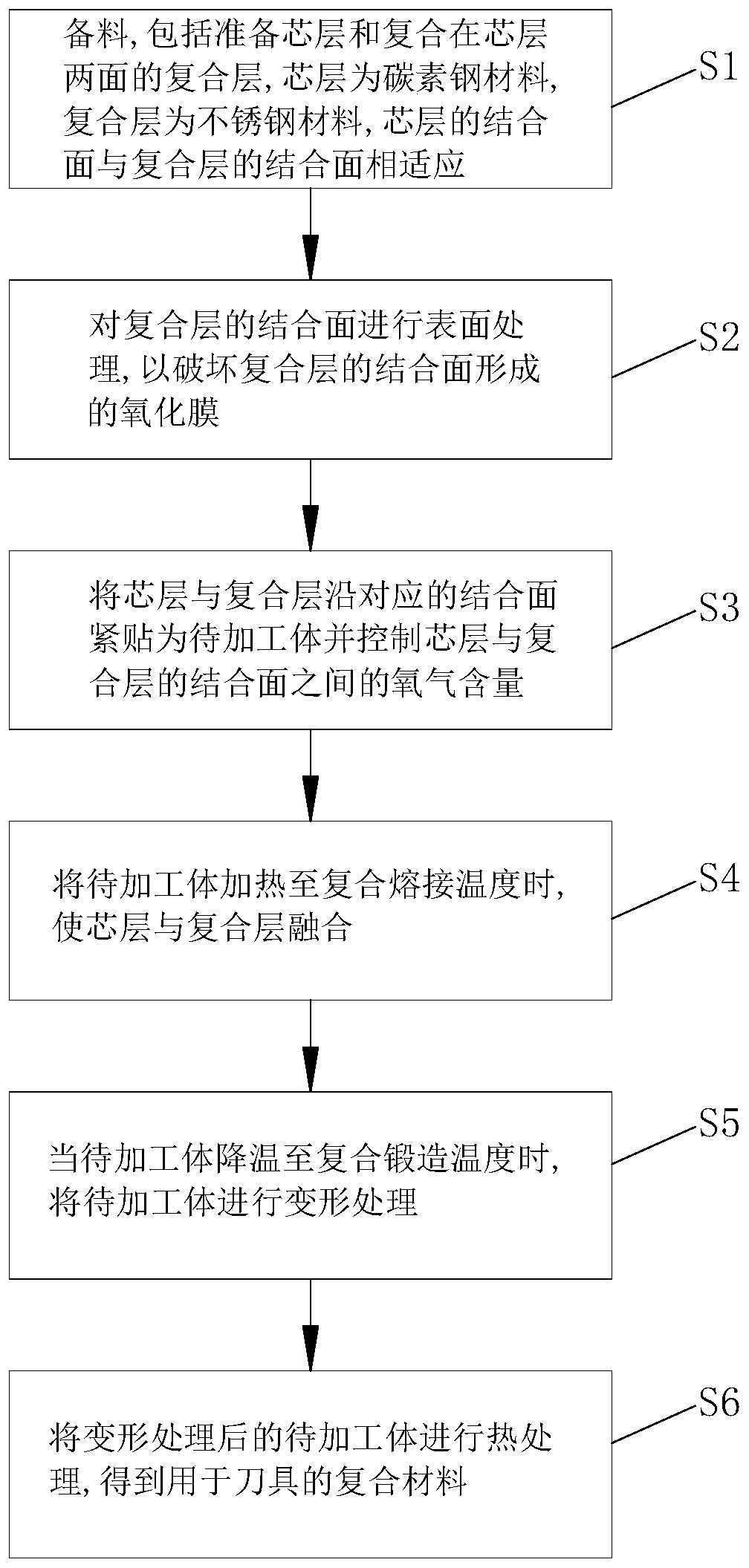

[0033] refer to figure 1 , at least one embodiment of the present invention provides a method for preparing a composite material for cutting tools, including:

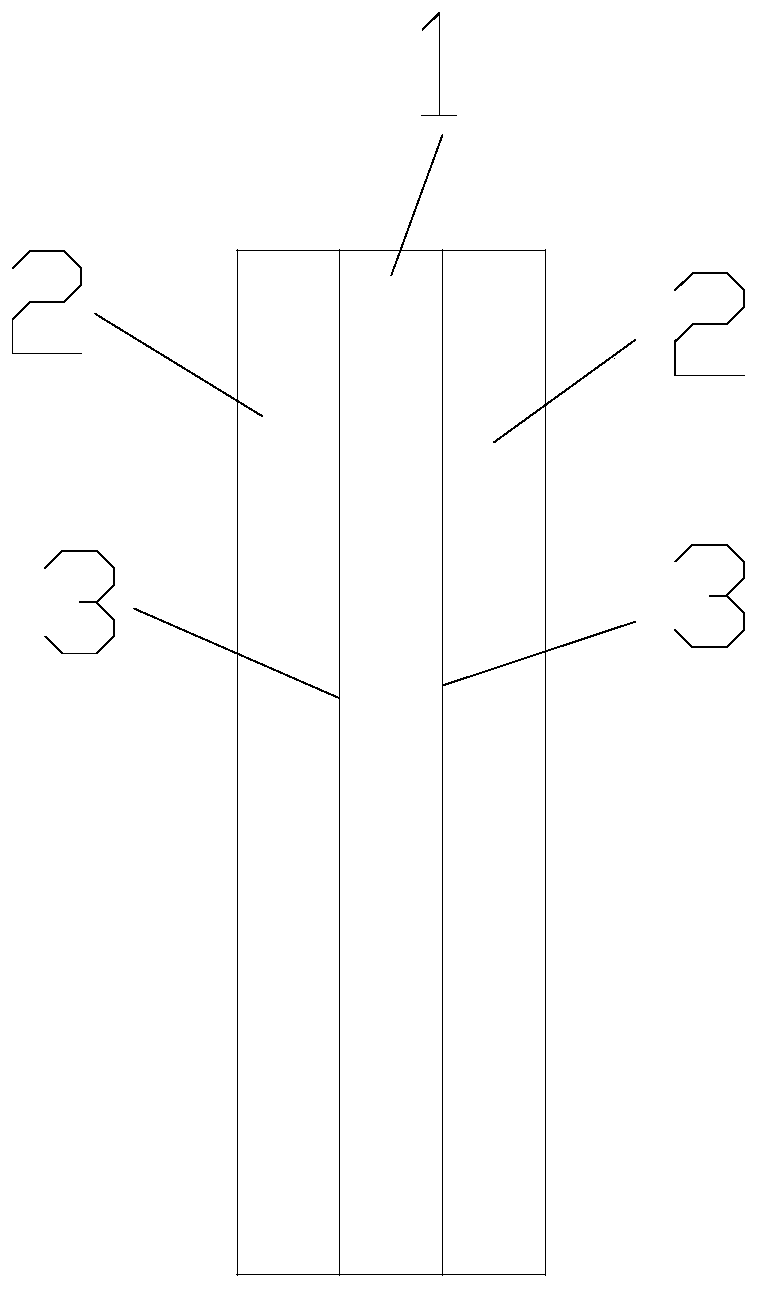

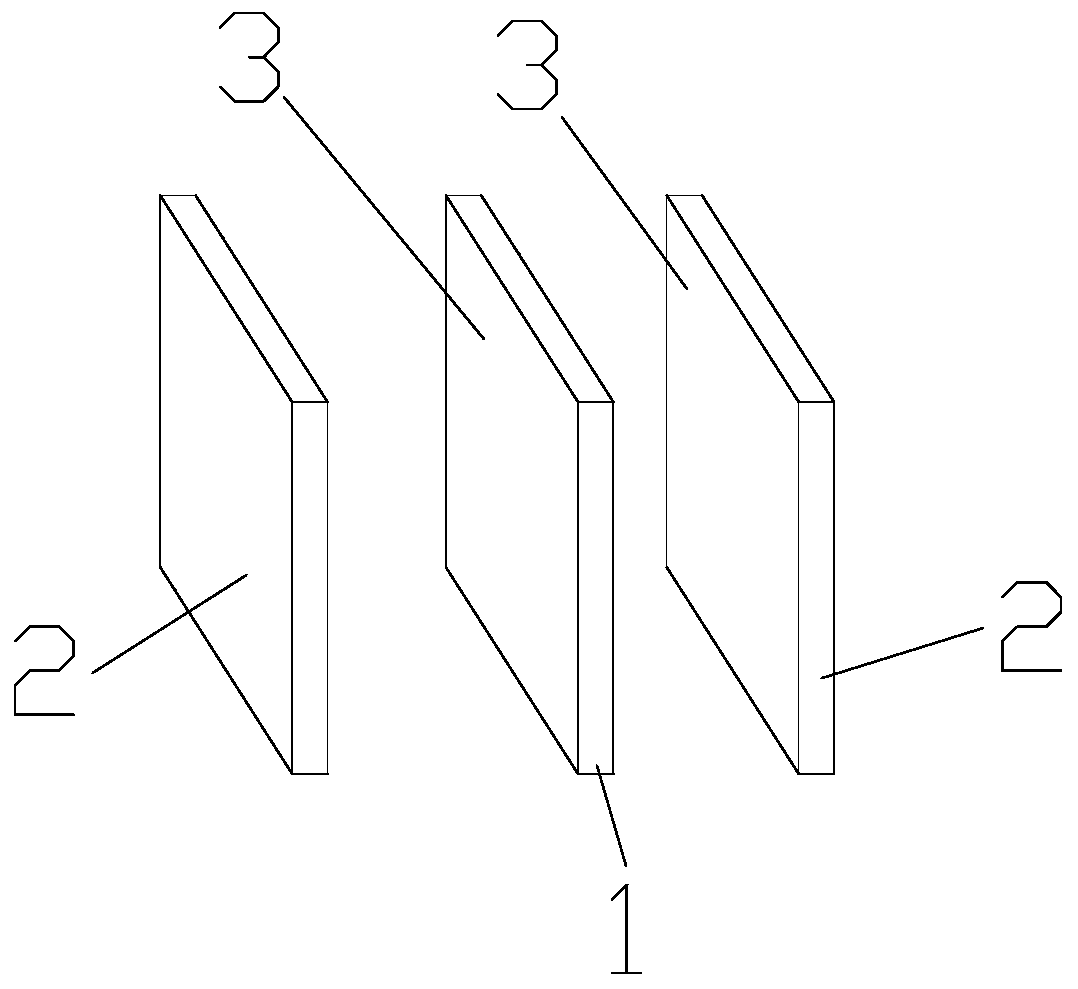

[0034] S1, preparing materials, including preparing a core layer and a composite layer compounded on both sides of the core layer, the core layer is a carbon steel material, the composite layer is a stainless steel material, the combination of the bonding surface of the core layer and the composite layer Face to face;

[0035] S2. Surface treatment is carried out on the bonding surface of the composite layer to destroy the oxide film formed on the bonding surface of the composite layer;

[0036] S3, sticking the core layer and the composite layer along the corresponding bonding surface as a body to be processed and controlling the oxygen content between the bonding surface of the core layer and the composite layer;

[0037] S4, heating the body to be processed to the composite welding temperature, so that the core la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com