High-strength steel fiber adhesive and preparation method thereof

A fiber adhesive, high-strength steel technology, applied in the directions of non-polymer adhesive additives, adhesive types, unsaturated alcohol copolymer adhesives, etc. Disintegration and other problems, to achieve the effect of strong anti-rust and anti-rust function, strong toughness and maintaining fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

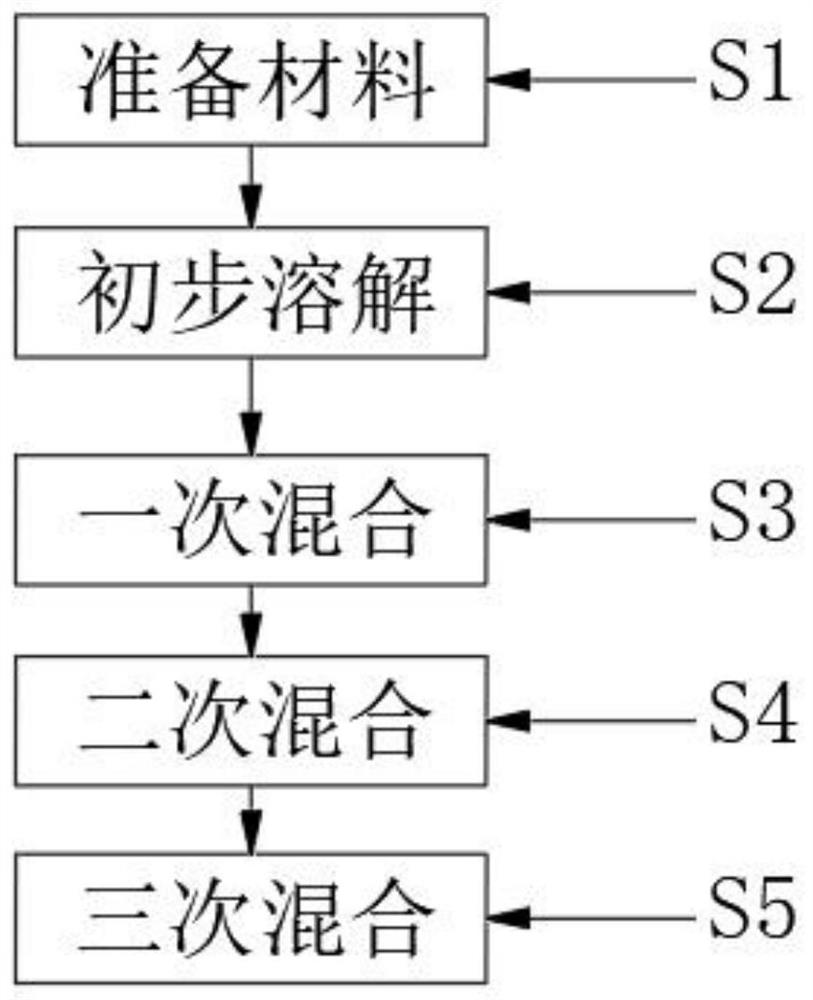

[0023] see figure 1 , the present invention provides a scheme: a high-strength steel fiber adhesive and a preparation method thereof, the high-strength steel fiber adhesive consists of vinyl acetate copolymer, polyvinyl alcohol, polyvinyl alcohol phosphated resin, Composed of amine-based adhesive agent, emulsifier and deionized water, the parts by weight and addition ratio of each composition are 60-80 parts of vinyl acetate copolymer, 6-8 parts of polyvinyl alcohol, polyvinyl alcohol phosphate 15-20 parts of chemical resin, 0.1-1.0 parts of amino-based bonding agent, 2-5 parts of emulsifier and 5-10 parts of deionized water.

[0024] The preparation method of above-mentioned a kind of high-strength steel fiber adhesive comprises the following steps:

[0025] S1. Preparation materials: Prepare 60-80 parts of vinyl acetate copolymer, 6-8 parts of polyvinyl alcohol, 15-20 parts of polyvinyl alcohol phosphated resin, 0.1-1.0 parts of amino-based glue, emulsifier 2-5 parts and 5...

Embodiment 1

[0032] A high-strength steel fiber adhesive and a preparation method thereof, the high-strength steel fiber adhesive consists of vinyl acetate copolymer, polyvinyl alcohol, polyvinyl alcohol phosphated resin, amine-based bonding agent, emulsifier Composed of deionized water, the parts by weight and addition ratio of each composition are 40 parts of vinyl acetate copolymer, 6 parts of polyvinyl alcohol, 15 parts of polyvinyl alcohol phosphated resin, and 0.1 part of amino-based adhesive , 2 parts of emulsifier and 5 parts of deionized water.

[0033] The preparation method of above-mentioned a kind of high-strength steel fiber adhesive comprises the following steps:

[0034]S1. Preparation materials: Prepare 40 parts of vinyl acetate copolymer, 6 parts of polyvinyl alcohol, 15 parts of polyvinyl alcohol phosphated resin, 0.1 part of amino-based adhesive agent, 2 parts of emulsifier and 5 parts of deionized water , put aside;

[0035] S2. Preliminary dissolution: Take 6 parts ...

Embodiment 2

[0041] A high-strength steel fiber adhesive and a preparation method thereof, the high-strength steel fiber adhesive consists of vinyl acetate copolymer, polyvinyl alcohol, polyvinyl alcohol phosphated resin, amine-based bonding agent, emulsifier Composed of deionized water, the parts by weight and addition ratio of each composition are 50 parts of vinyl acetate copolymer, 7 parts of polyvinyl alcohol, 16 parts of polyvinyl alcohol phosphated resin, and 0.4 part of amino-based adhesive , 3 parts of emulsifier and 7 parts of deionized water.

[0042] The preparation method of above-mentioned a kind of high-strength steel fiber adhesive comprises the following steps:

[0043] S1. Preparation materials: 50 parts of vinyl acetate vinyl acid copolymer, 7 parts of polyvinyl alcohol, 16 parts of polyvinyl alcohol phosphated resin, 0.4 part of amino-based adhesive, 3 parts of emulsifier and 7 parts of deionized water, put aside;

[0044] S2. Preliminary dissolution: Take 7 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com