End face ring-type deep groove machining cutter

A technology for machining tools and deep grooves, which is used in manufacturing tools, metal processing equipment, tools for lathes, etc. , the effect of reducing heat and increasing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

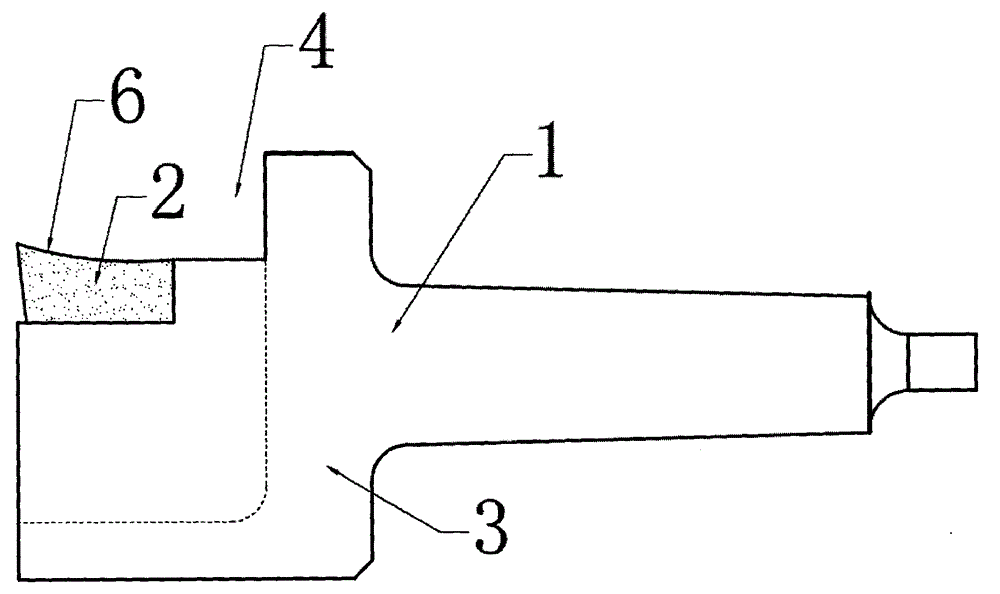

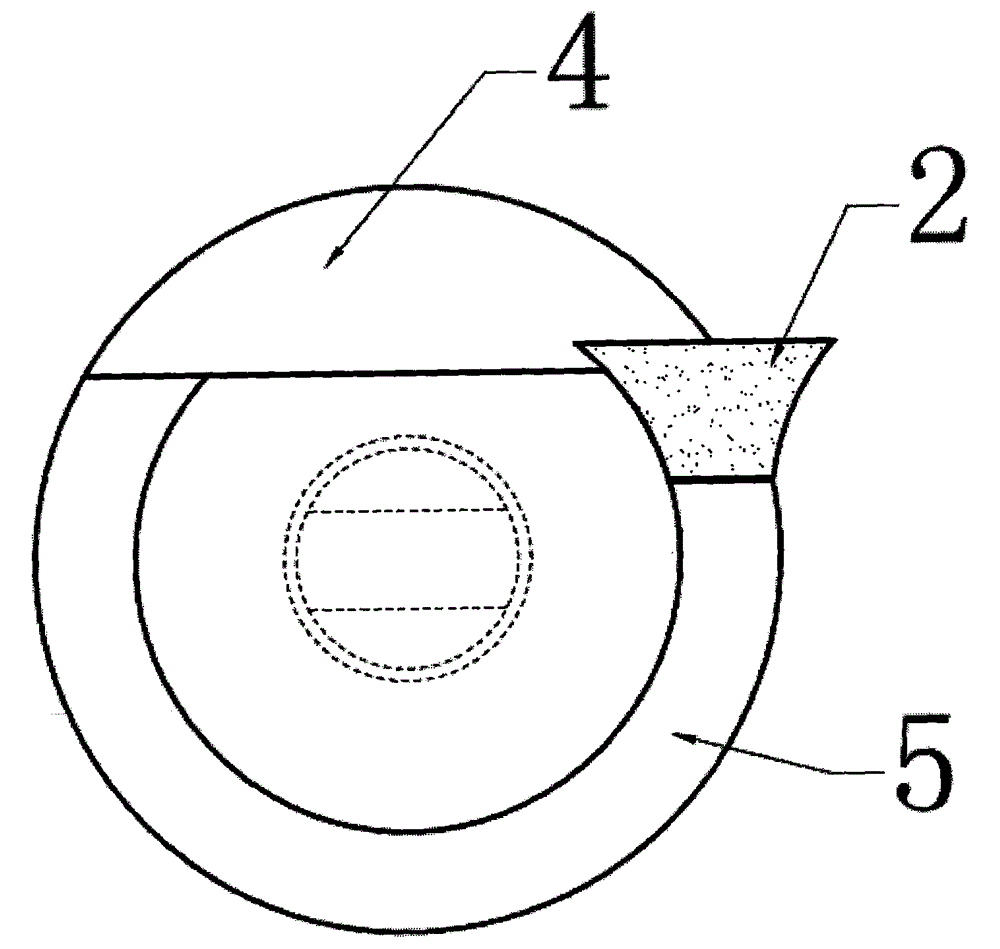

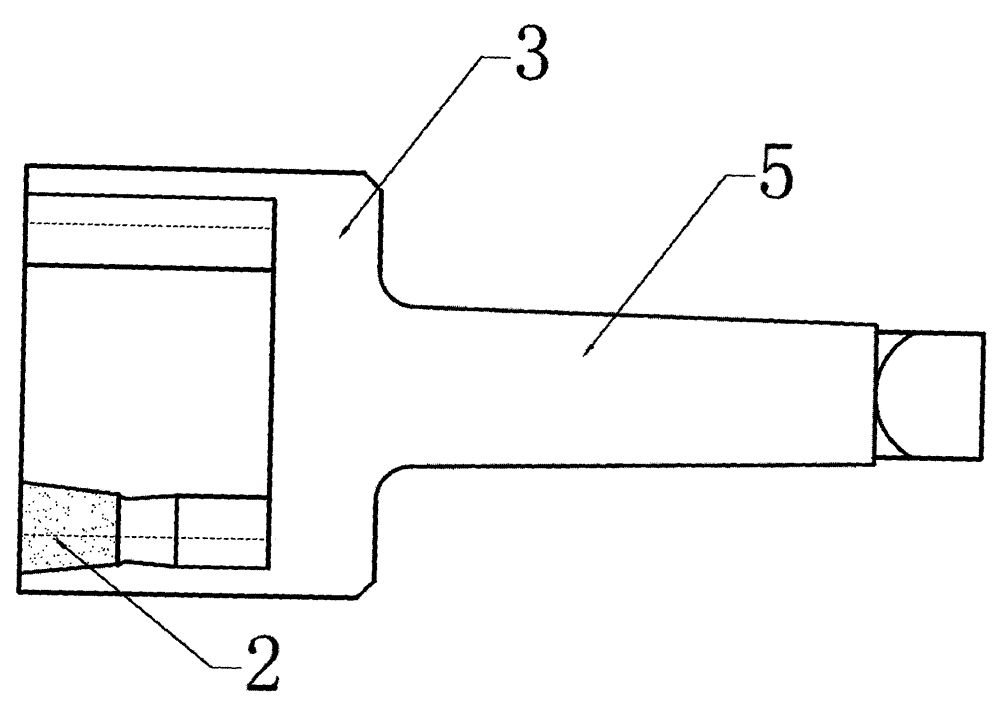

[0021] Such as figure 1 , figure 2 and image 3 The shown tool for machining deep grooves with an end face ring includes a cutter body and a blade. The cutter body includes a handle that matches the tailstock hole of the machine tool, and a cylindrical insert seat connected to the handle. One end of the blade holder is fixedly connected with the knife handle shown, and a gap is opened at the end of the other end, and the blade is fixedly connected to the cylinder wall of the gap.

[0022] The length of the notch at the end of the cylindrical blade seat is not less than two-sixth of the circumference of the cylindrical blade shaft, and the depth of the notch is consistent with the depth of the cylindrical blade seat.

[0023] The horizontal front face of the blade is ground with R120, and the depth of the chamfer is 2.5mm.

[0024] The blade is a bar-shaped struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com