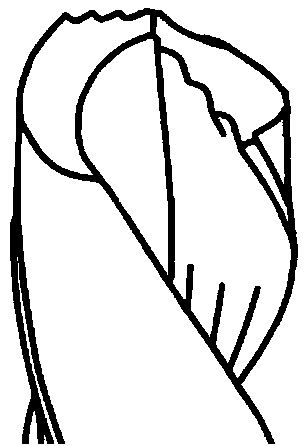

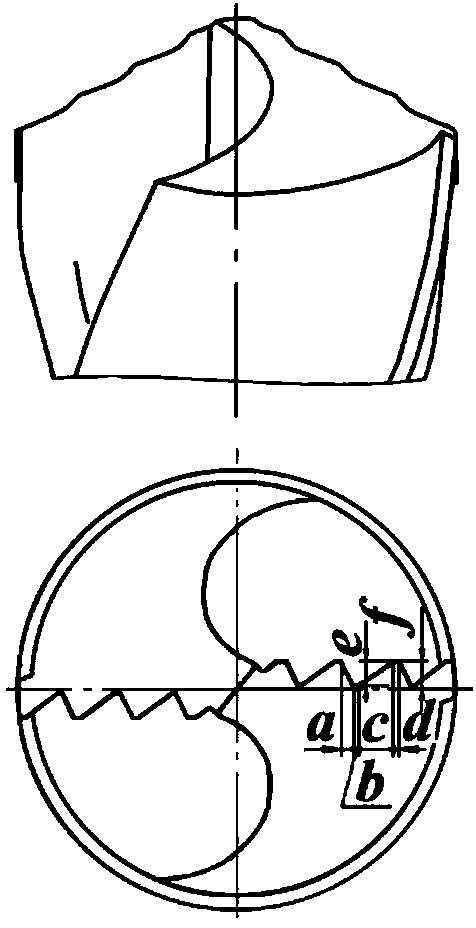

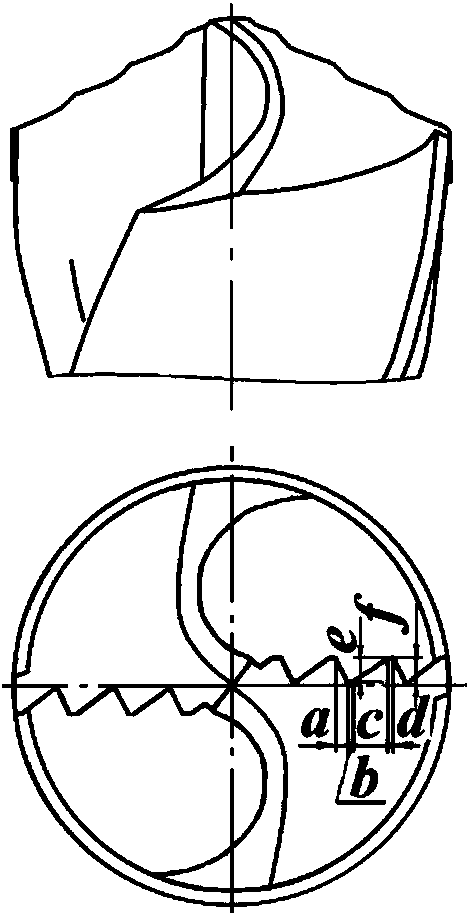

Twist drill with grooved front tool faces and bent blades

A technology of twist drill and rake face, which is applied in the direction of twist drill, etc., can solve the problems of complex twist drill sharpening structure and sharpening method, poor drilling performance and energy saving effect, and difficulty in popularization, so as to achieve drilling efficiency and cutting tool Improved durability, easy promotion and application, and good centering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0035] In the twist drill of the present invention, the helicoid part of the main edge rake face has several small helical grooves, and these small helical grooves are similar to the helical grooves, and are formed as a set of periodic curves / curves based on the projection on the twist drill end plane. The broken line or the non-periodic meander / bend line is formed by spiral motion around the drill axis as the occurrence line.

[0036] In the present invention, the number of helical grooves on the twist drill, the depth of the grooves and the cross-sectional shape of the grooves can all be changed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com