Perforating knife

A hole cutter and cutter body technology, which is applied in the field of punching cutters, can solve the problems of hole flanging, reduced hole forming accuracy, and inability to adapt to punching process requirements, and achieves the effect of convenient knife sharpening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

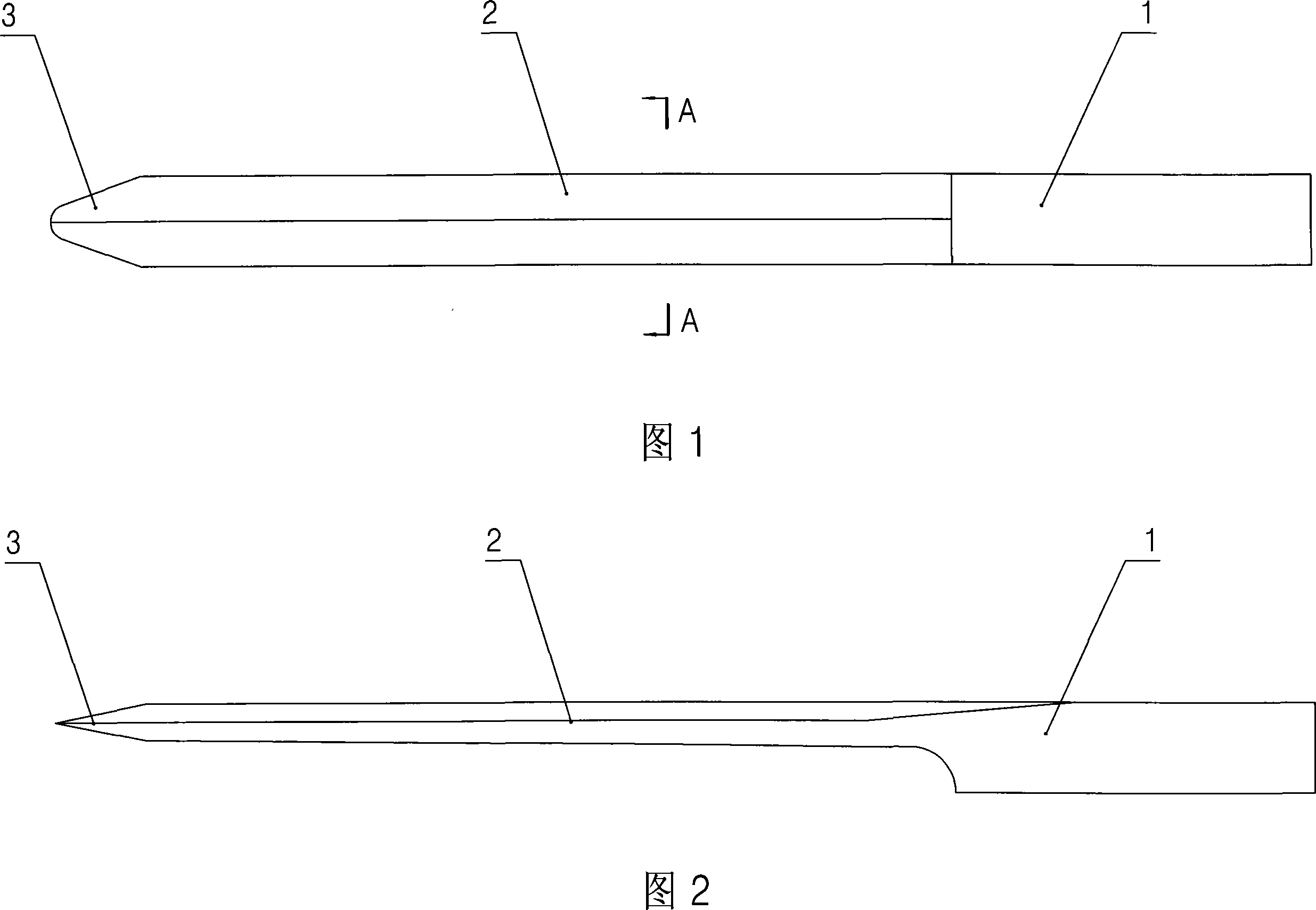

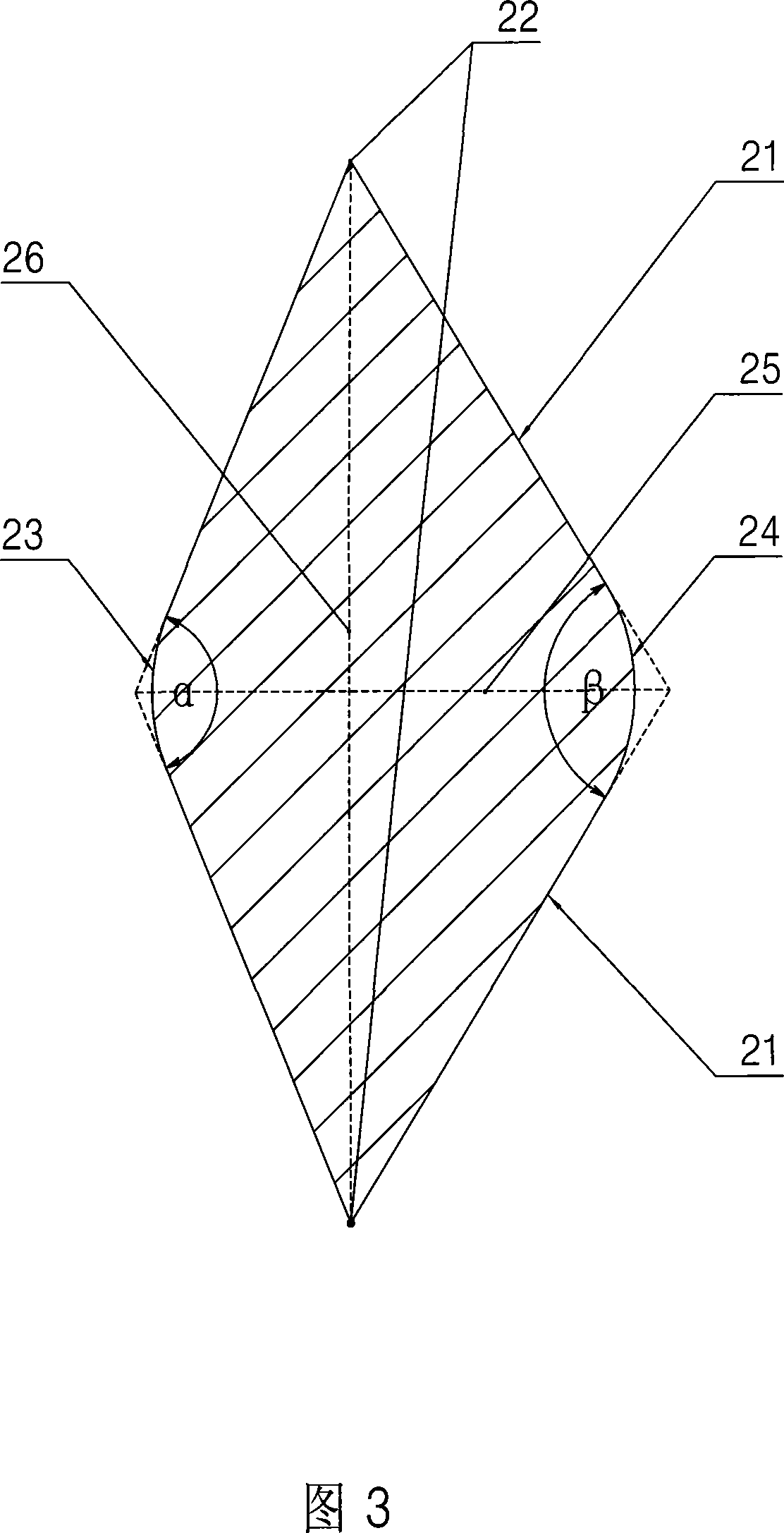

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] As shown in Fig. 1 and Fig. 2, the perforating knife according to the present invention comprises: a knife handle 1 and a knife body 2 arranged on the knife handle 1, and the end of the knife body 2 is a knife tip 3, as shown in Fig. 3 As shown, the cross-section of the cutter body 2 is a quadrilateral with unequal diagonals and is mirror-symmetrical along the short diagonal 25. The quadrilateral is located at the inner and outer angles α and β is not equal, the outer angle α is greater than the inner angle β, and the two sides of the cutter body 2 forming the inner angle β are the grinding surfaces 21—the blade can be sharpened by grinding the two grinding surfaces 21, and the cutter body 2. Blades 22 are respectively provided at the two endpoints of the long diagonal line 26, so that the punching knife can be punched in both positive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com