Deep hole boring cutter

A deep hole boring tool and tool body technology, which is applied in the direction of cutting blades, accessories of tool holders, and tools used in lathes, etc., can solve the problem of uneven force on the cutting edge and extrusion edge, increasing the difficulty of tool sharpening, and cutting tools Expensive manufacturing costs and other issues to achieve the effect of preventing chips and coolant from splashing around, reducing the overall weight of the tool, and facilitating disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

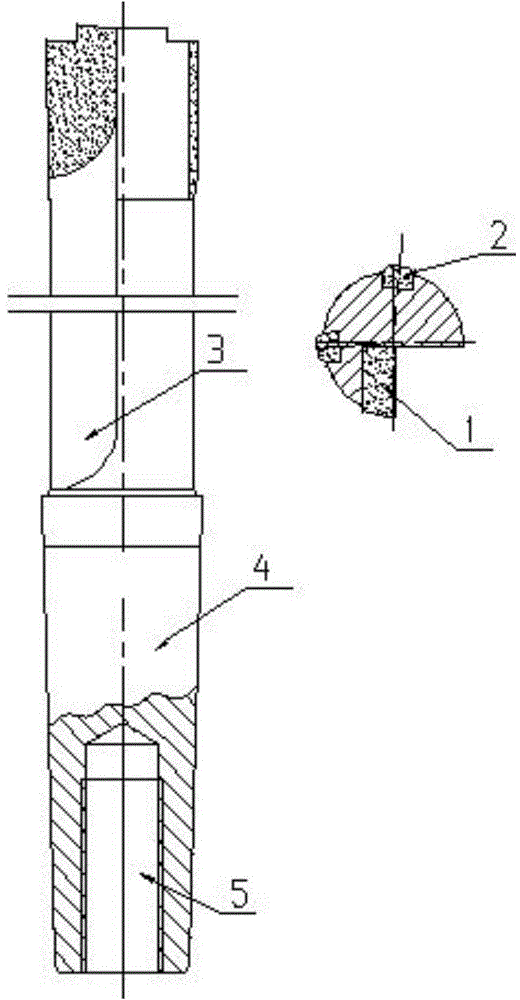

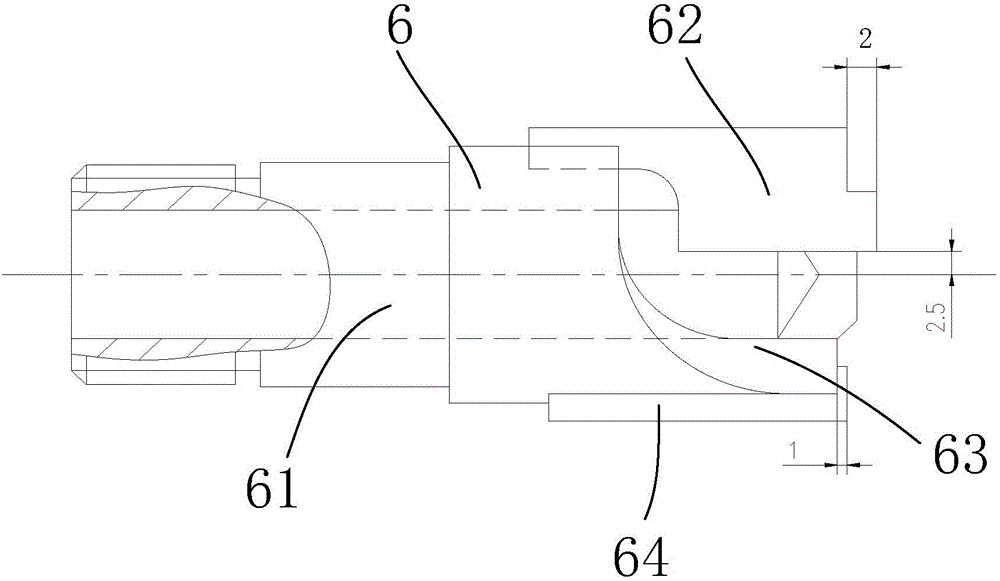

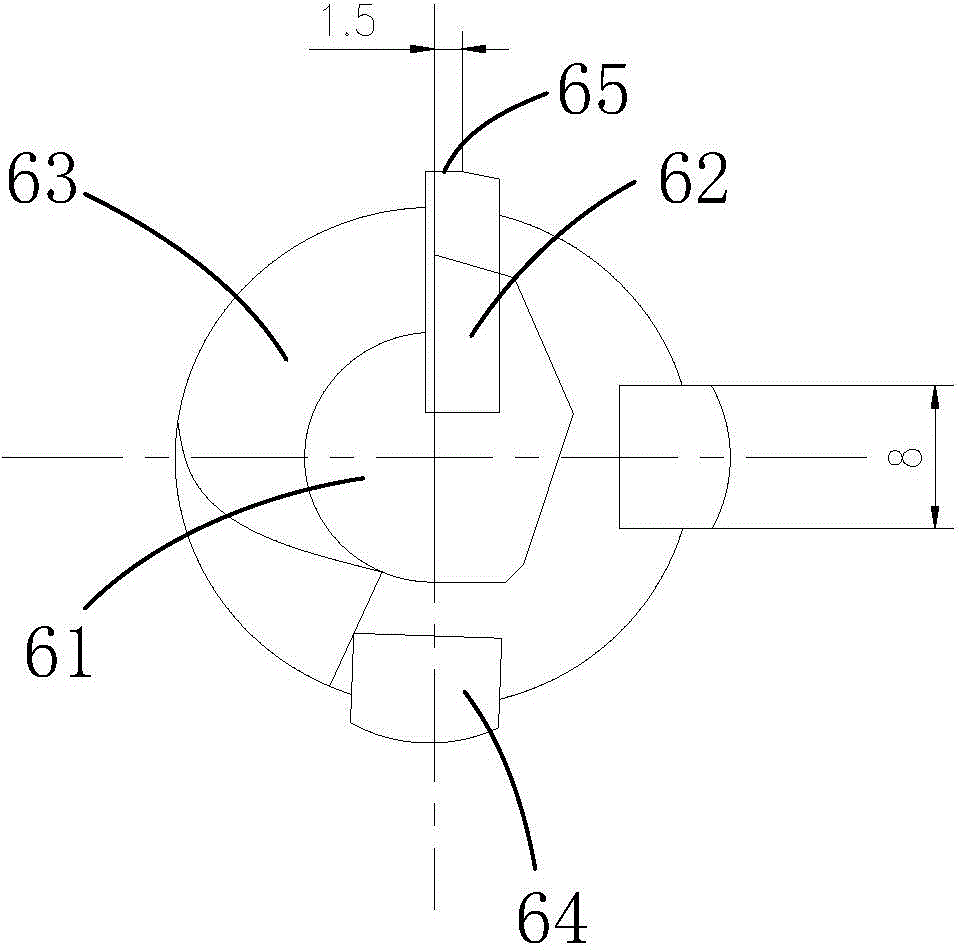

[0032] Such as figure 1 As shown, the traditional boring tool is installed on the spindle of the machine tool through the Morse taper shank 4, the workpiece is fixed on the tooling, the spindle drives the tool to rotate, and the workpiece is fed along the guide rail to complete the boring process. The specific operation process is as follows: the excess material is cut off by the cutting edge 1, and then the machined surface is squeezed by the extrusion edge 2, and the chips are discharged through the chip discharge groove 3.

[0033] Due to the heavy weight of the tool, the centrifugal force generated during the rotation of the spindle is likely to cause uneven force on the cutting edge 1 and the extrusion edge 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com