Machining method for protection cover part

A processing method and technology for a protective cover, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as mechanical damage and product surface wrinkling, and achieve the effect of improving quality, forming good quality and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

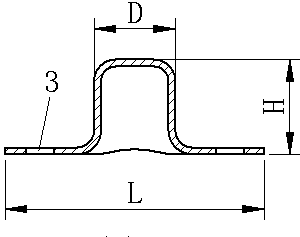

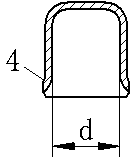

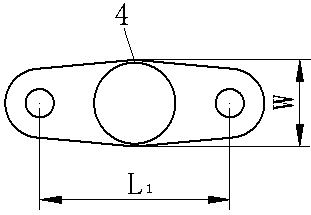

[0026] The part processed in this example is a protective cover for protecting self-locking nuts. figure 1 is the front view of the part, figure 2 yes figure 1 left section view of image 3 yes figure 1 top view of Figure 4 is a 3D broken-out view of the part. Depend on Figure 1 to Figure 4 It can be seen that the part includes a cover body 1, and the cover body 1 is a cylinder with a closed top. Symmetrical ear pieces 2 are provided on both sides of the bottom of the cover body 1 , and fixing holes 3 are provided on the ear pieces 2 . During use, coat the anti-rust grease in the cover body 1 of the part, cover the self-locking nut to prevent the self-locking nut from rusting, and then pass the fixing hole 3 on the ear piece 2 of the part with a screw to connect with the substrate.

[0027] The part will have the following characteristics;

[0028] 1. The thickness of the part is only 0.8, which belongs to thin-walled parts.

[0029] 2. The lugs 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com