Curtain height cutting device

A cutting device and high-level technology, which is applied in the cutting of textile materials, other manufacturing equipment/tools, textiles and papermaking, etc., can solve the problems of fabric wrinkles, easy scratches, low work efficiency, etc., and achieve good fabric flatness, Guaranteed cutting efficiency and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

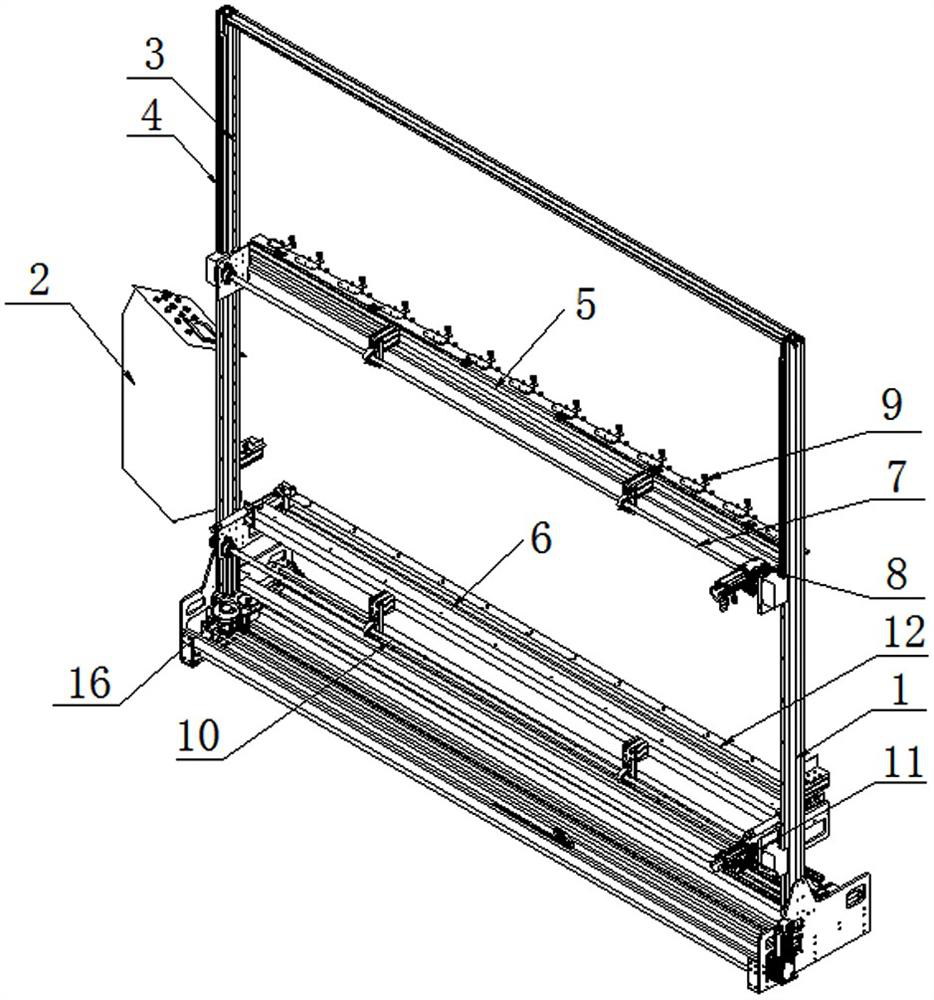

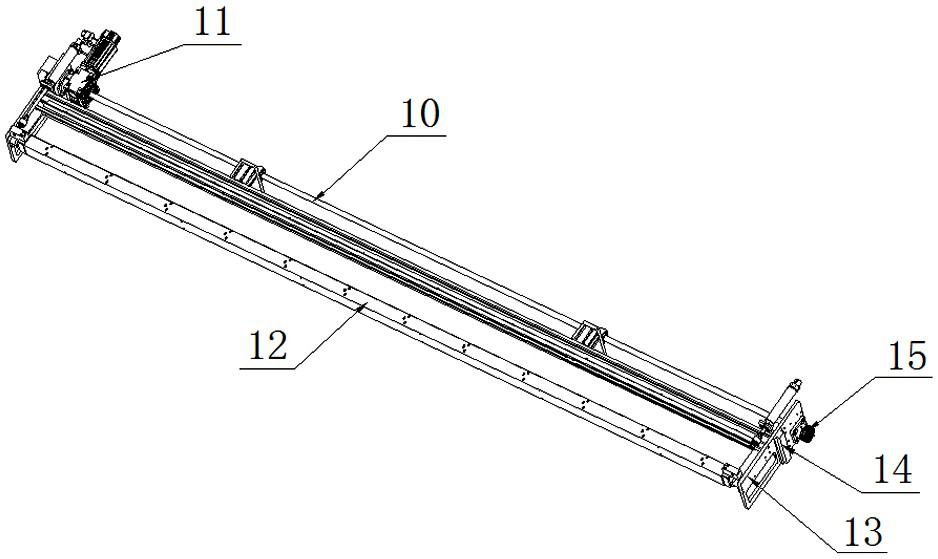

[0018] as attached figure 1 , figure 2 As shown, a curtain height cutting device includes a column 1 and a control cabinet 2. Guide rails 3 are respectively provided on the opposite inner sides of the column 1, and racks 4 are respectively provided on the two outer surfaces of the column 1. The column 1 is provided with a primary lifting assembly 5 and a secondary lifting assembly 6. The primary lifting assembly 5 includes a mounting plate, a servo motor 8, a shaft 7, a slider I, gears and several small pneumatic clamps 9, and the secondary lifting assembly 6 includes a mounting plate 13, a servo motor 11, a shaft 10, a slider I14, a gear 15 and a large pneumatic clamp 12, such as figure 2 Shown is the secondary lifting assembly 6 , in which the two ends of the shaft 10 are connected with a gear 15 , the gear 15 is matched with the rack 4 , and the slider I14 is matched with the guide rail 3 .

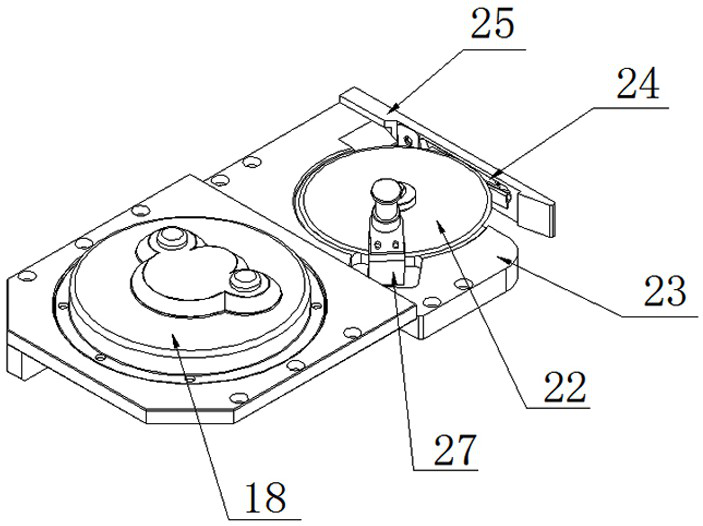

[0019] as attached image 3 , Figure 4 As shown, there is a flying butterfl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com