Device for spirally grinding back knife face of spiral drill based on electrospark wire cutting

A technology of electric discharge wire and twist drill, which is applied in the direction of twist drills, drilling tool accessories, drilling/drilling equipment, etc., can solve the problems of grinding burns on the flank surface, and achieve no grinding burns, simple structure, and cutting edge grind easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

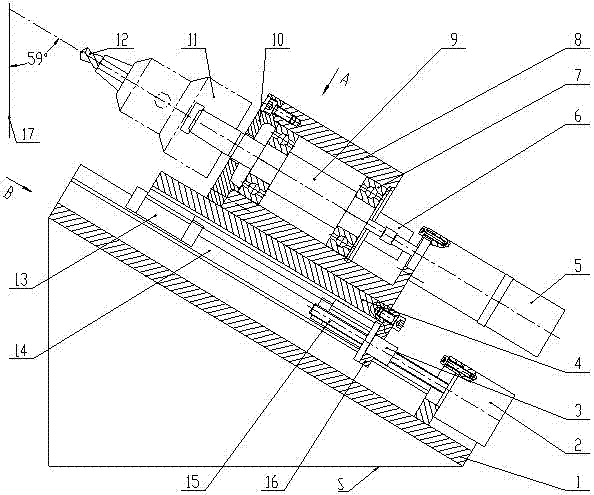

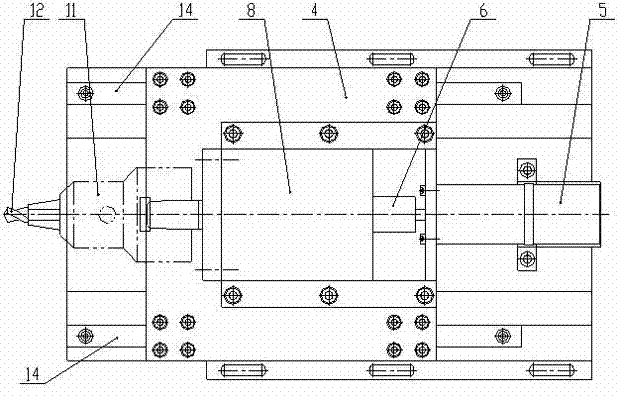

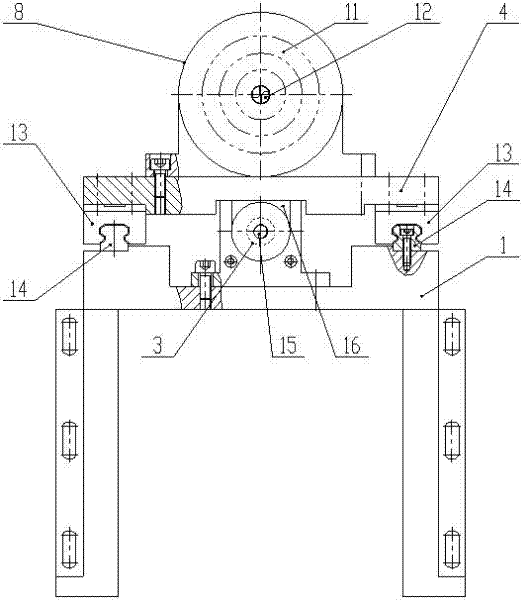

[0011] Such as figure 1 , figure 2 with image 3 As shown, the present invention provides a kind of twist drill flank helical sharpening device based on wire electric discharge cutting, including twist drill 12, rotary shaft 9, ball screw nut pair, rolling guide rail pair and frame 1; The drill 12 is installed on one end of the rotary shaft 9 through the three-jaw drill chuck 11 of the wrench, and the other end of the rotary shaft 9 is connected with the first stepping motor 5 through the coupling 6, and the first stepping motor 5 is also connected with the reducer; The rotary shaft 9 is installed in the bearing housing 8 through the bearing 7, the bearing cover 10 on the bearing housing 8 is used for axially fixing the bearing 7, and the connecting plate 4 is fixed on the bottom of the bearing housing 8; the ball screw nut pair is composed of a scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com