Hard tooth surface gear finish turning process and design method of tooth turning tool of hard tooth surface gear

A design method and technology of hardened tooth surface, applied in the direction of gear tooth manufacturing tools, gear tooth manufacturing devices, manufacturing tools, etc., can solve the problems of low processing efficiency and processing accuracy, more restrictions, long development cycle, etc., to achieve guaranteed The effect of processing efficiency and rough cutting accuracy, reducing use cost and reducing processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

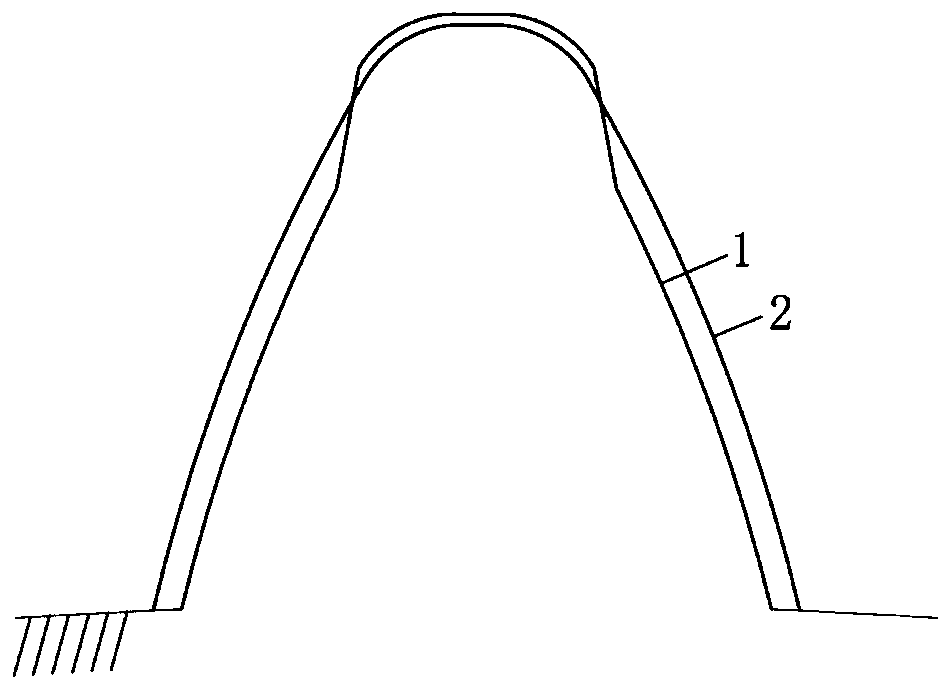

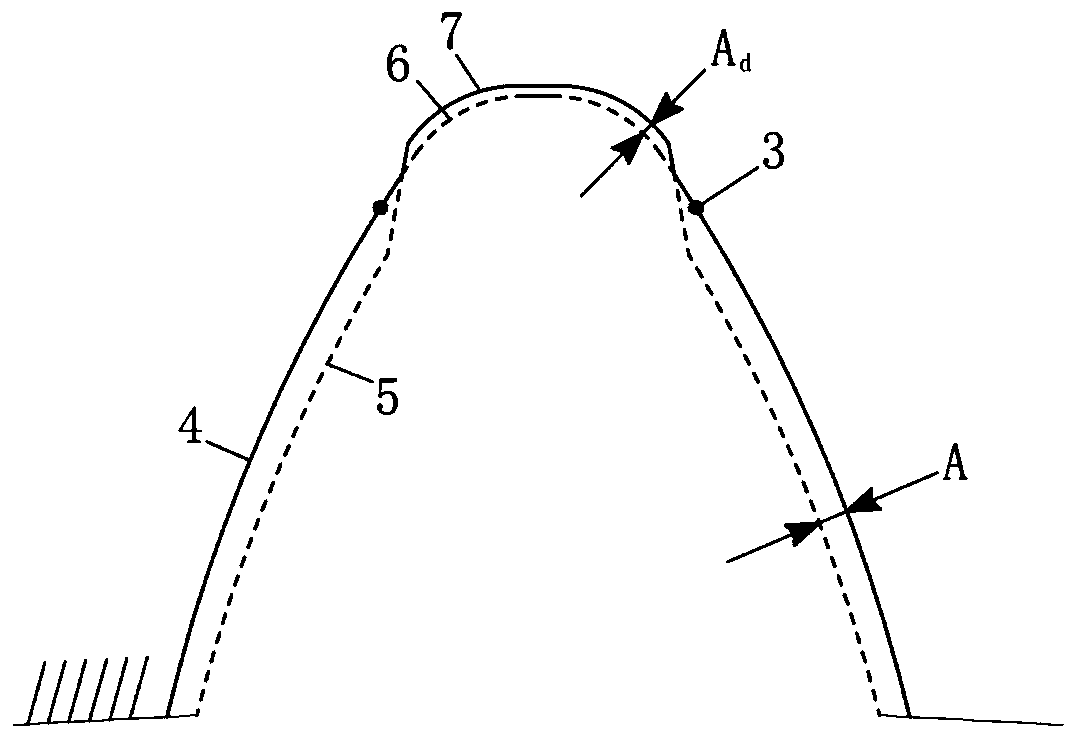

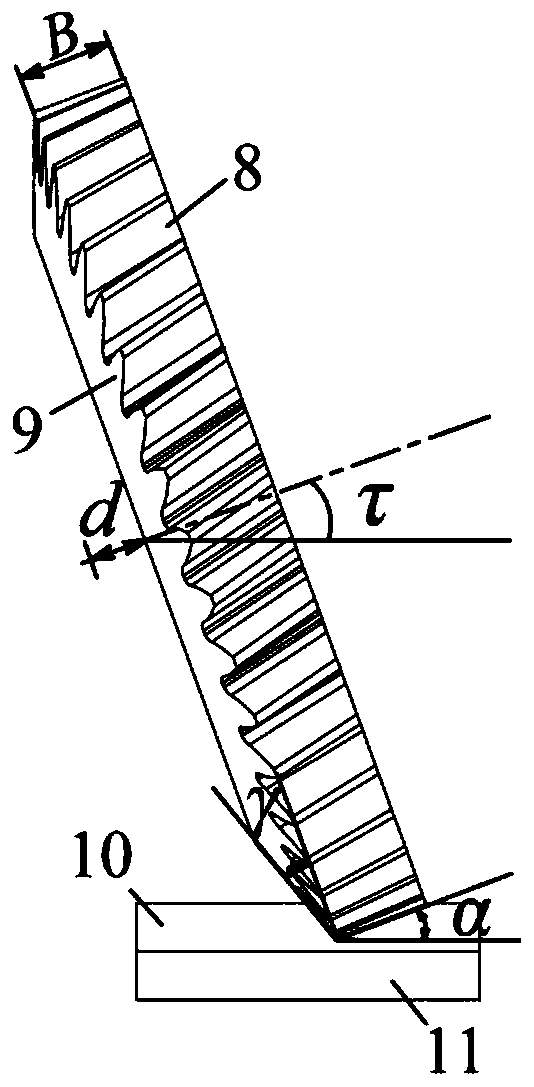

[0036] In the embodiment, the inner bevel ring is selected as the processing object of the hardened gear, and the workpiece parameters are shown in Table 1. The rough machining of the gear workpiece 11 adopts the gear turning process, and the rough cutting and fine cutting of the workpiece are carried out on the same gear turning machine tool, which can shorten the processing cycle and reduce the production cost. When designing a rough-cut gear cutting tool, the profile of the rough-cut blade 1 should have a design for root digging and grinding, and the tooth profile of the involute part of the workpiece must not be cut off when digging the root. For the gear workpiece 11 (see image 3 ) after rough machining, a machining allowance A is left on the tooth surface 10 of the workpiece, and the tooth root of the workpiece is slightly dug out, and the digging amount is A d , the root digging area must not exceed the end point 3 of the tooth profile, such as figure 2 shown. After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com