Finger cutter type helical bevel gear processing device

A processing device and milling cutter technology, which is applied in the direction of driving device, feeding device, metal processing equipment, etc., can solve the problems of many adjustment links, troublesome operation process, and many transmission parts, and achieve simple adjustment, simple structure, and short transmission chain Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

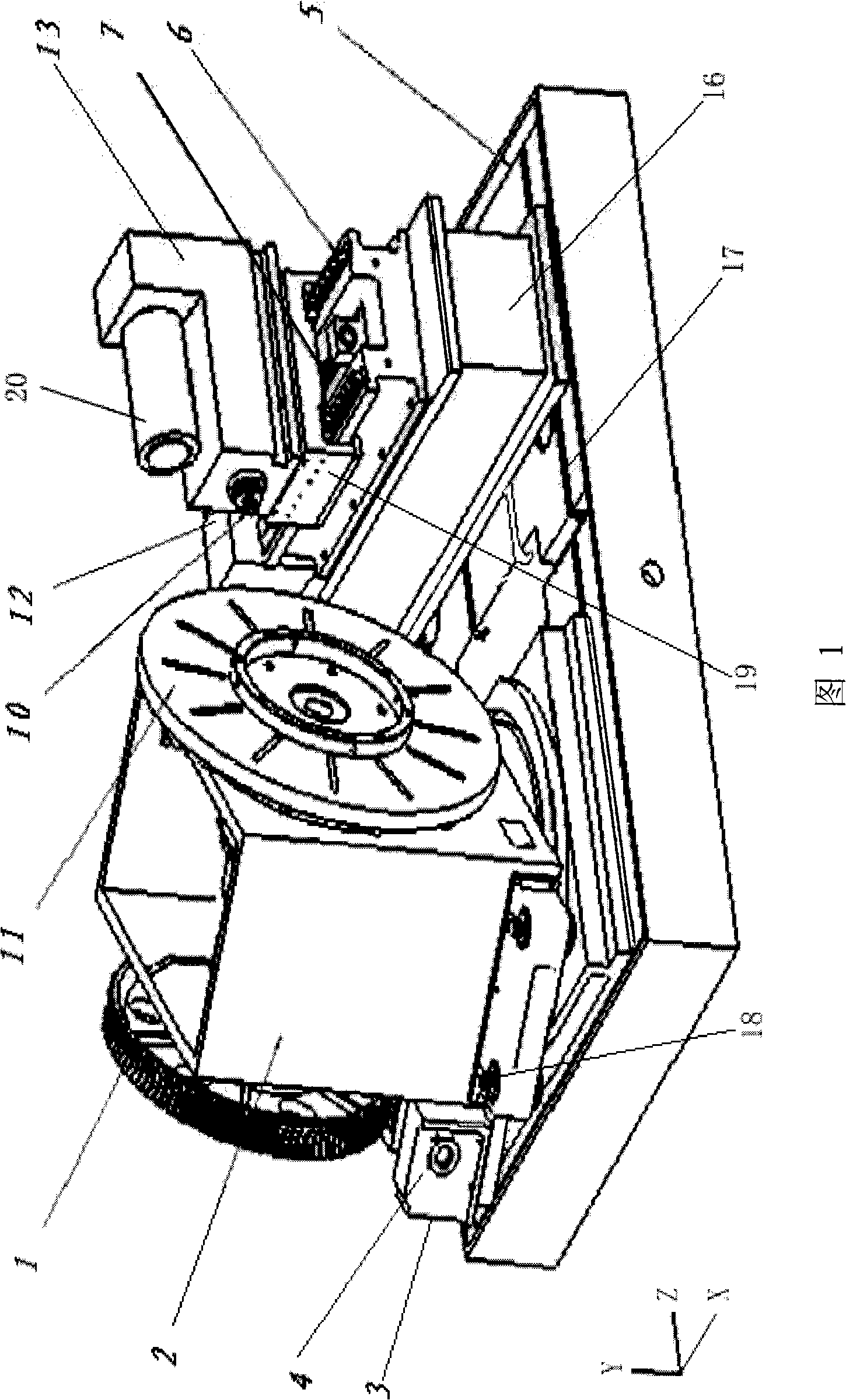

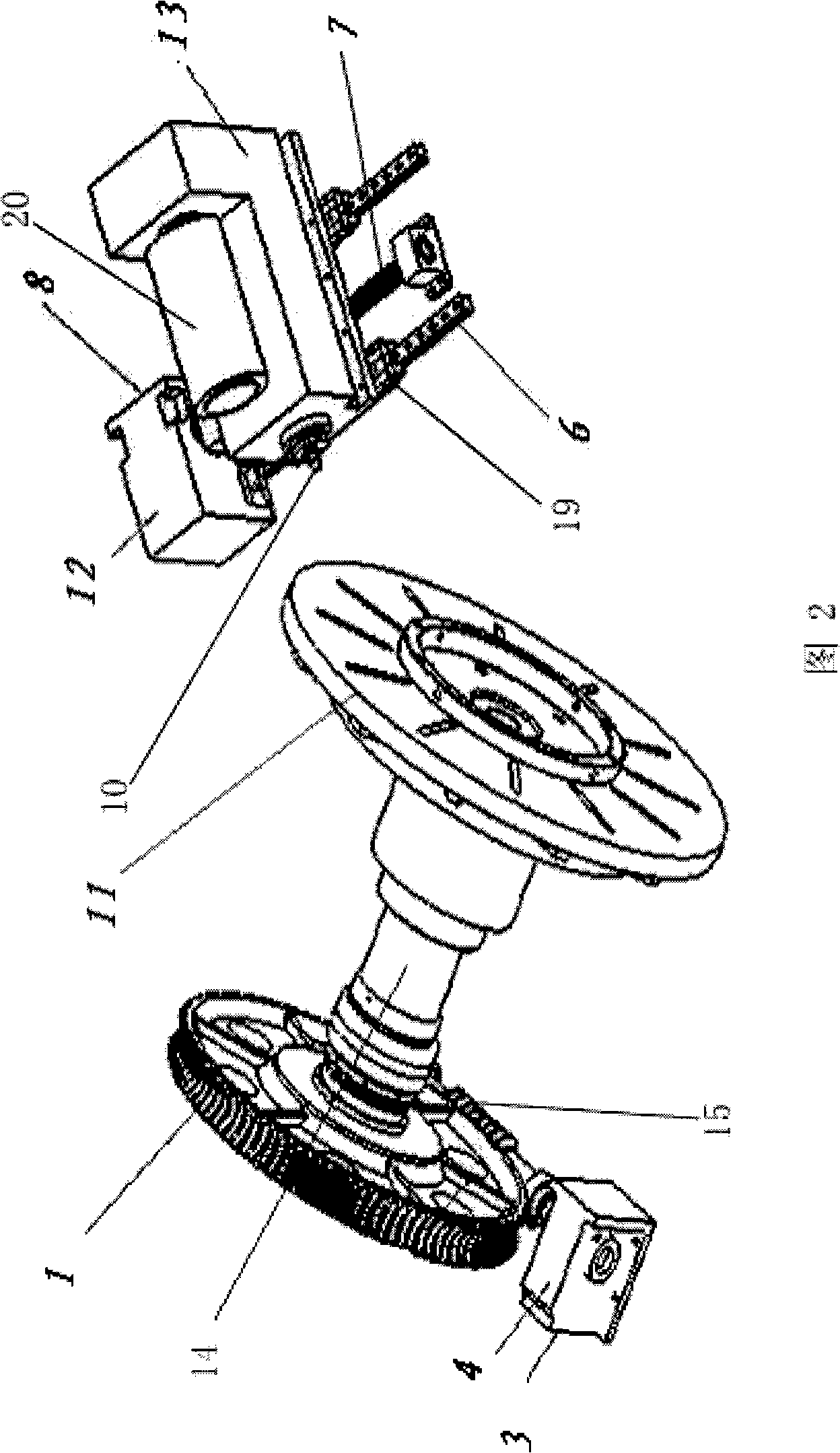

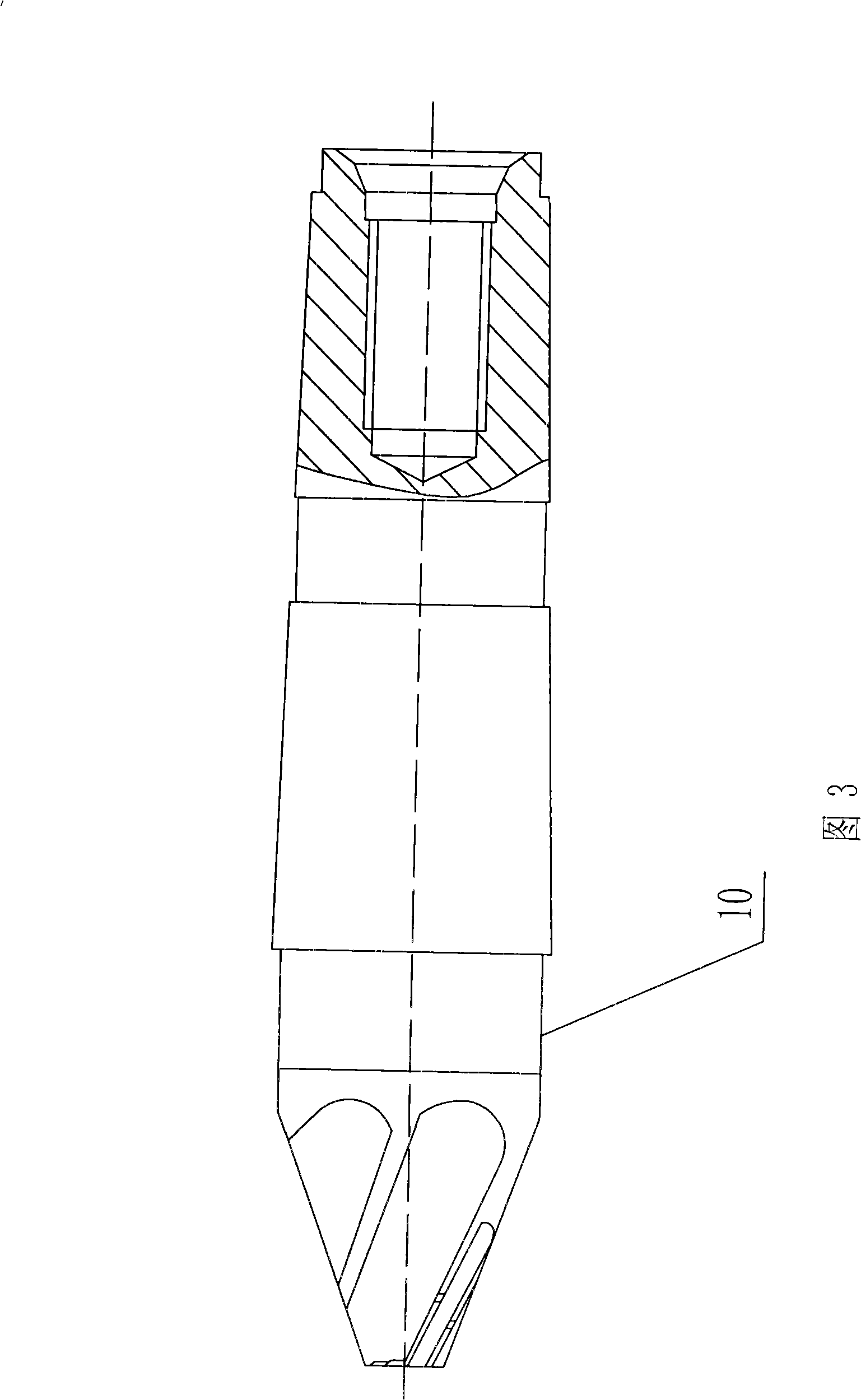

[0014] As shown in Fig. 1 and Fig. 2, the milling machine of the present invention comprises a bed 5, and the both sides of the bed 5 are respectively equipped with a workpiece box 2 and a tool base 16, and the workpiece box 2 is rotatably assembled on the bed 5, and the workpiece box 2 is The rotating shaft around is the vertical Y axis. The workpiece case 2 is provided with bolts 18 for fixed positioning with the bed 5. The workpiece case 2 is equipped with a workpiece main shaft 14 for rotation. Outside the front and rear case surfaces, one end of the workpiece spindle 14 is fixedly connected with the workpiece face plate 11 for fixing the workpiece on the outside of the front case surface of the workpiece case 2, and the other end of the workpiece spindle 14 is fixed with a worm gear on the outside of the workpiece case 2 rear case surface. 1. A worm 15 connected to the worm wheel 1 is provided under the worm wheel 1. One end of the worm 15 is connected to the reducer 4 fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com