A tooling for submerged arc welding arc ignition and extinguishment

A submerged arc welding and arc extinguishing technology, used in arc welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as inability to perform rapid and continuous construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

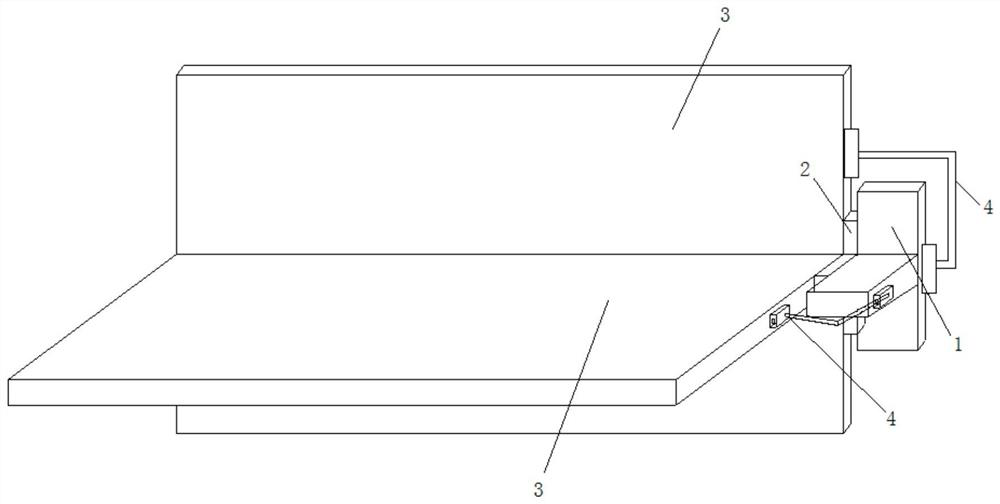

[0029] see figure 1 , is a tooling for submerged arc welding arc ignition and arc extinguishment provided by the embodiment of the present invention, such as figure 1 As shown, the tooling includes a connecting piece 1, and the connecting piece 1 includes at least two plates abutted against each other and joined together; the connecting piece 1 is used to realize arc ignition or arc extinguishing when welding; the connecting piece 1 It can be used instead of the arc striking and extinguishing plate in the prior art.

[0030] A ceramic liner 2, one end surface of the ceramic liner 2 is used to abut against the end surface of the base material 3 of the machine to be welded, and the other end surface is used to abut against the end surface of the connector 1;

[0031] A magnetic clamp assembly, which is used to fix the connecting piece 1 and the base material 3 to be welded; specifically, when making the magnetic clamp assembly, the magnetic clamp assembly includes two sets of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com