Method for manufacturing microwave printed circuit board with step groove

A manufacturing method and step groove technology, which are applied in printed circuit manufacturing, printed circuit, electrical components, etc., can solve the problems that the microstrip pattern microstrip medium at the bottom of the step groove cannot be protected, and the pure polytetrafluoroethylene gasket is easy to fall off, etc. Achieve good glue resistance effect, simple manufacturing process and wide range of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

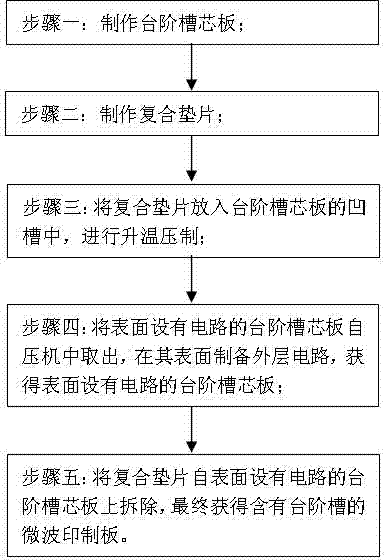

[0030] see figure 1 , a method for manufacturing a microwave printed board containing stepped grooves, the steps are as follows:

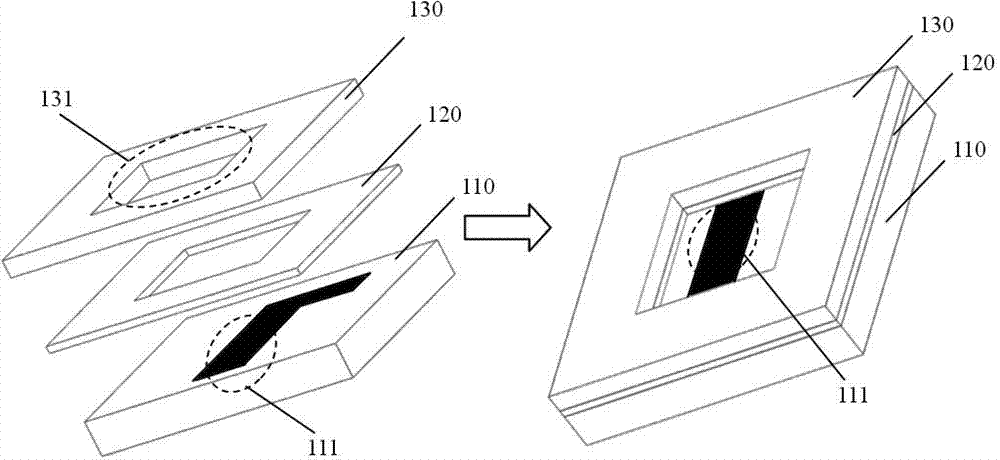

[0031] Step 1: Make the step groove core board. The step groove core plate includes three layers from bottom to top: bottom core plate 110, core plate adhesive film 120 and window layer core plate 130, such as figure 2 shown.

[0032] The bottom core board 110 is a circuit board with a bottom microwave circuit on its surface. The bottom microwave circuit is composed of two parts: a microwave sub-circuit 111 that needs to be exposed and a microwave sub-circuit that does not need to be exposed. The window layer core board 130 is a circuit board with a window 131 on the board, and the window 131 on the window layer core board 130 corresponds to the position of the exposed microwave sub-circuit 111 on the surface of the bottom core board 110 . The core board bonding film 120 is a thin film consistent with the shape of the window layer core board....

Embodiment 2

[0048] see figure 1 , a method for manufacturing a microwave printed board containing stepped grooves, the steps are as follows:

[0049] Step 1: Make the step groove core board. The core plate of the step groove is composed of three layers from bottom to top: the bottom core plate 110, the core plate adhesive film 120 and the window layer core plate 130, as figure 2 shown. The bottom core board 110 is a circuit board with a bottom microwave circuit on its surface. The bottom microwave circuit is composed of two parts: a microwave sub-circuit 111 that needs to be exposed and a microwave sub-circuit that does not need to be exposed. The window layer core board 130 is a multilayer circuit board with a window 131 on the board, and the window 131 on the window layer core board 130 corresponds to the position of the exposed microwave sub-circuit 111 on the surface of the bottom core board 110 . The core board bonding film 120 is a thin film consistent with the shape of the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com