Hollow building block

A hollow block and hollow technology, which is applied in the field of hollow blocks, can solve the problems of destroying farmland, yielding little effect, reducing the load-bearing capacity and thermal insulation performance of the wall, and achieving the effects of ensuring compactness, improving strength and thermal insulation and sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

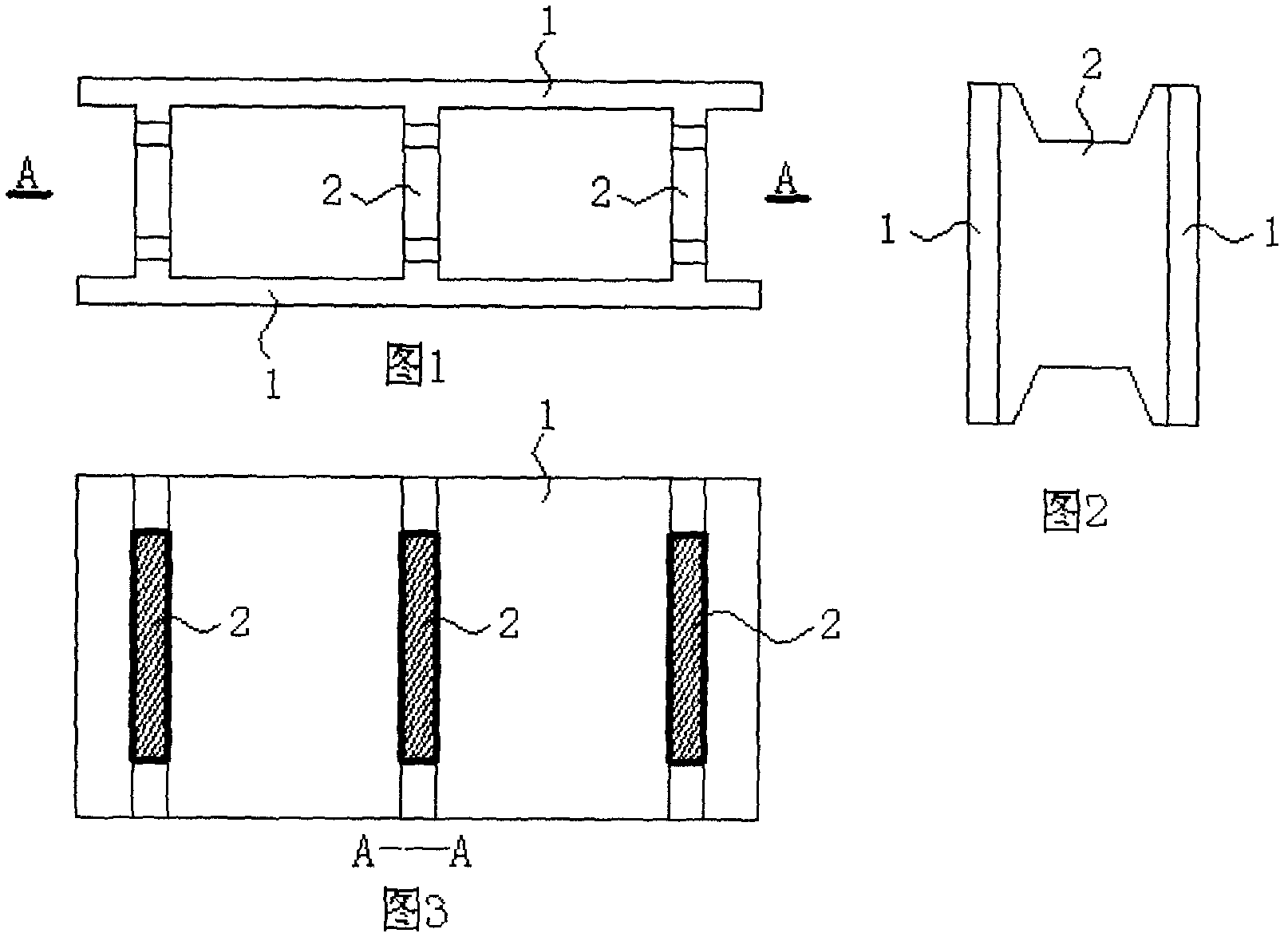

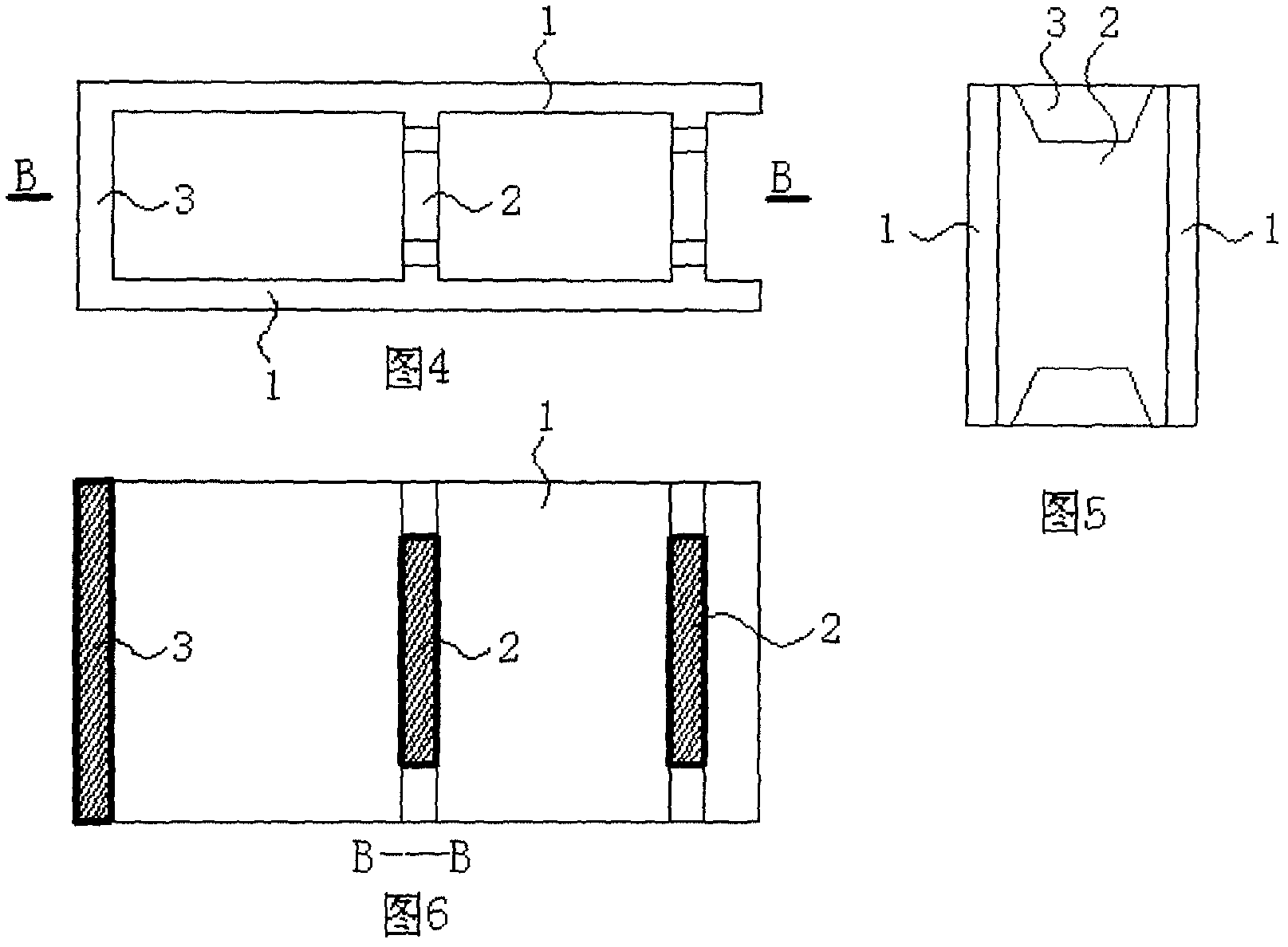

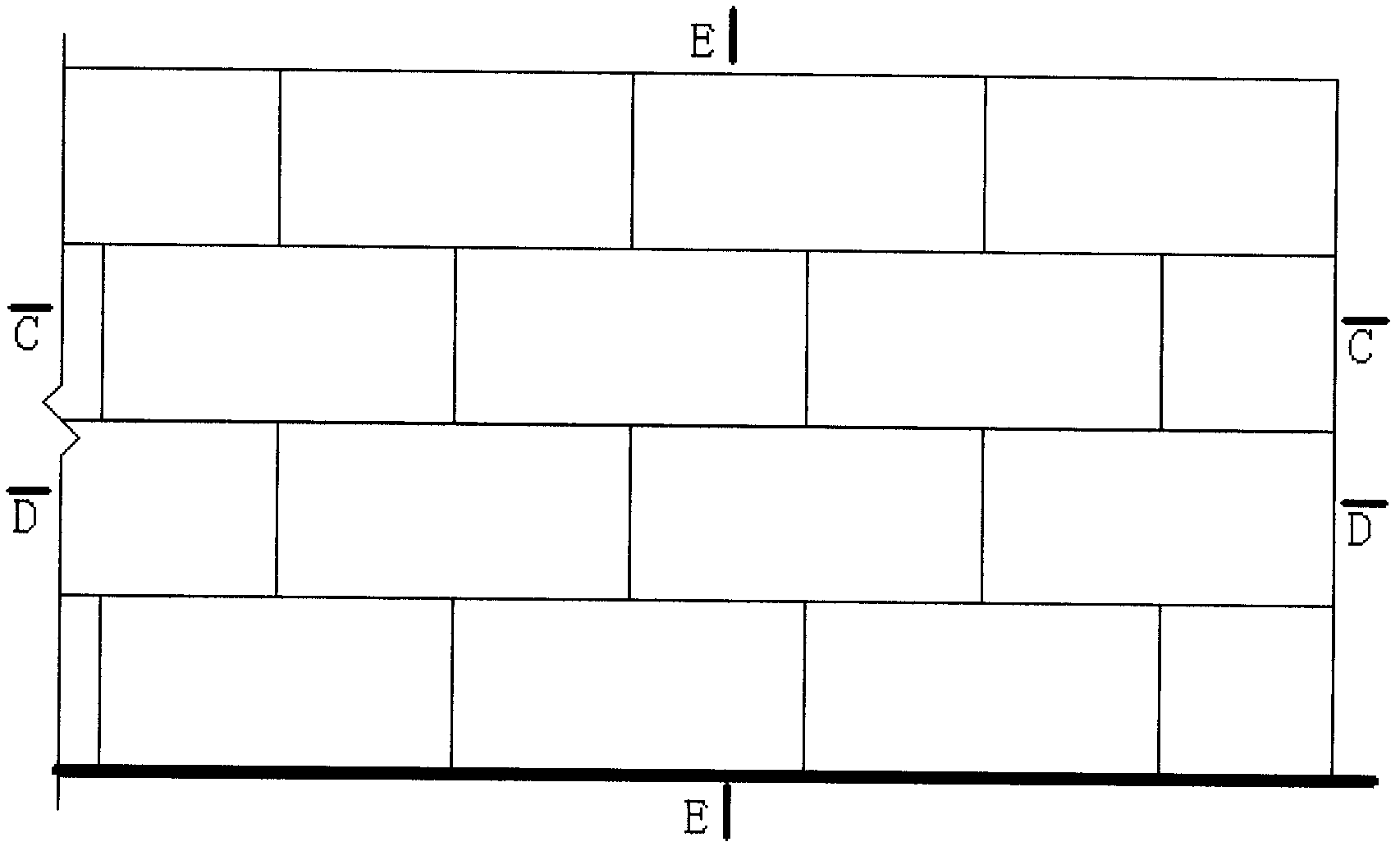

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0027] Such as Figure 1-8 As shown, a hollow block is composed of an outer wall (1), a connecting plate (2), and a sealing plate (3). The standard hollow block (4) is composed of an outer wall (1) and a connecting plate (2), and is suitable for the middle part of the wall. The non-standard hollow block (6) is composed of an outer wall (1), a connecting plate (2) and a sealing plate (3), and is used at corners of walls, openings of doors and windows, and edges of walls.

[0028] The connecting plates (2) at both ends of the hollow block are 50mm away from the end of the outer wall (1), and when two horizontal hollow blocks are butted, a vertical cavity (5) is formed. A trapezoidal groove is arranged above the connecting plate (2), and a trapezoidal groove is also arranged below the connecting plate (2). After the upper and lower layers of hollow blocks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com