Thermal creep plastic forming method for special-shaped aluminum alloy wall plate with variable thicknesses

A technology of plastic forming and thermal creep, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult control of shape accuracy, poor surface quality, long forming cycle of parts, etc., to shorten the forming cycle and improve surface quality Good, high dimensional accuracy and surface accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

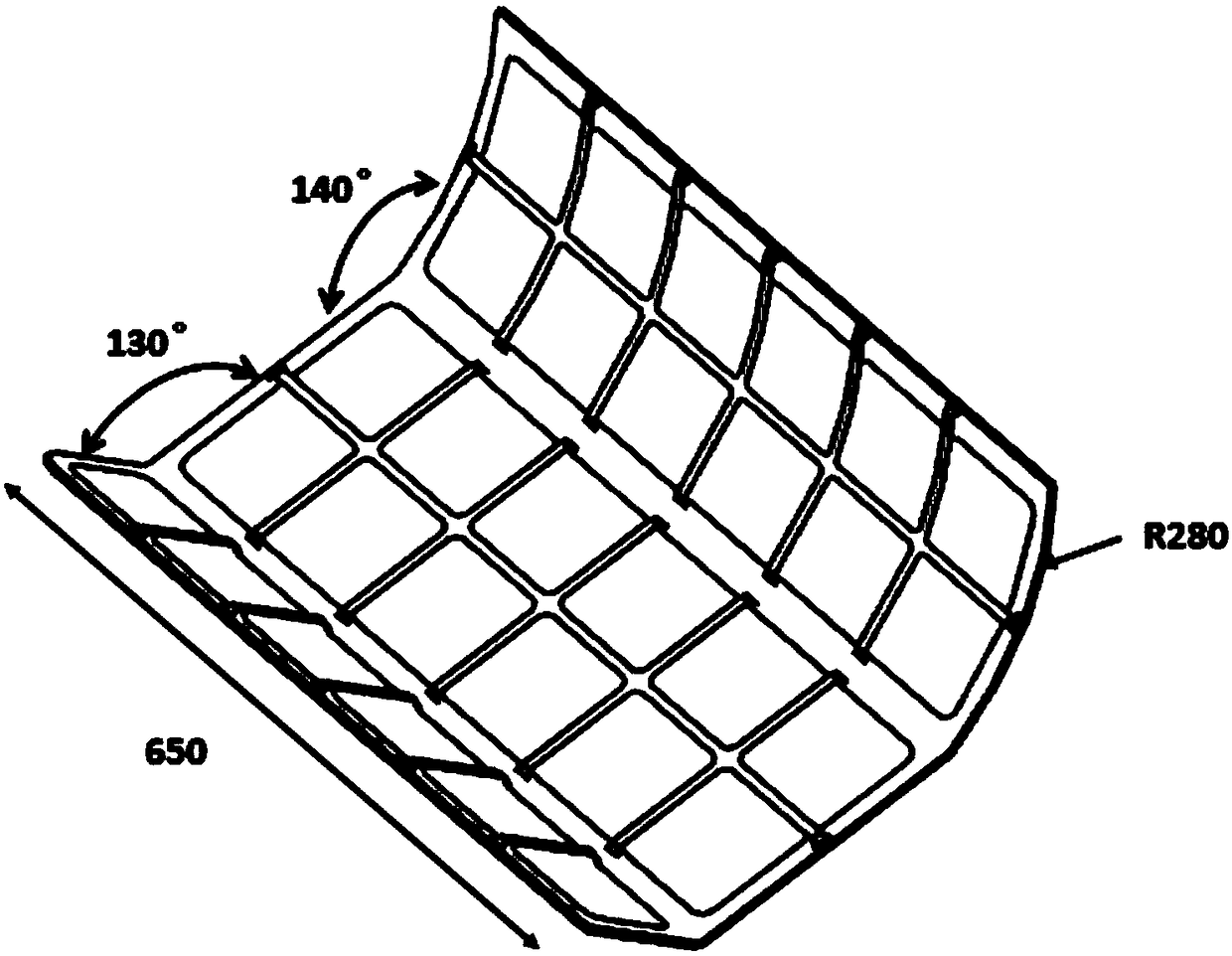

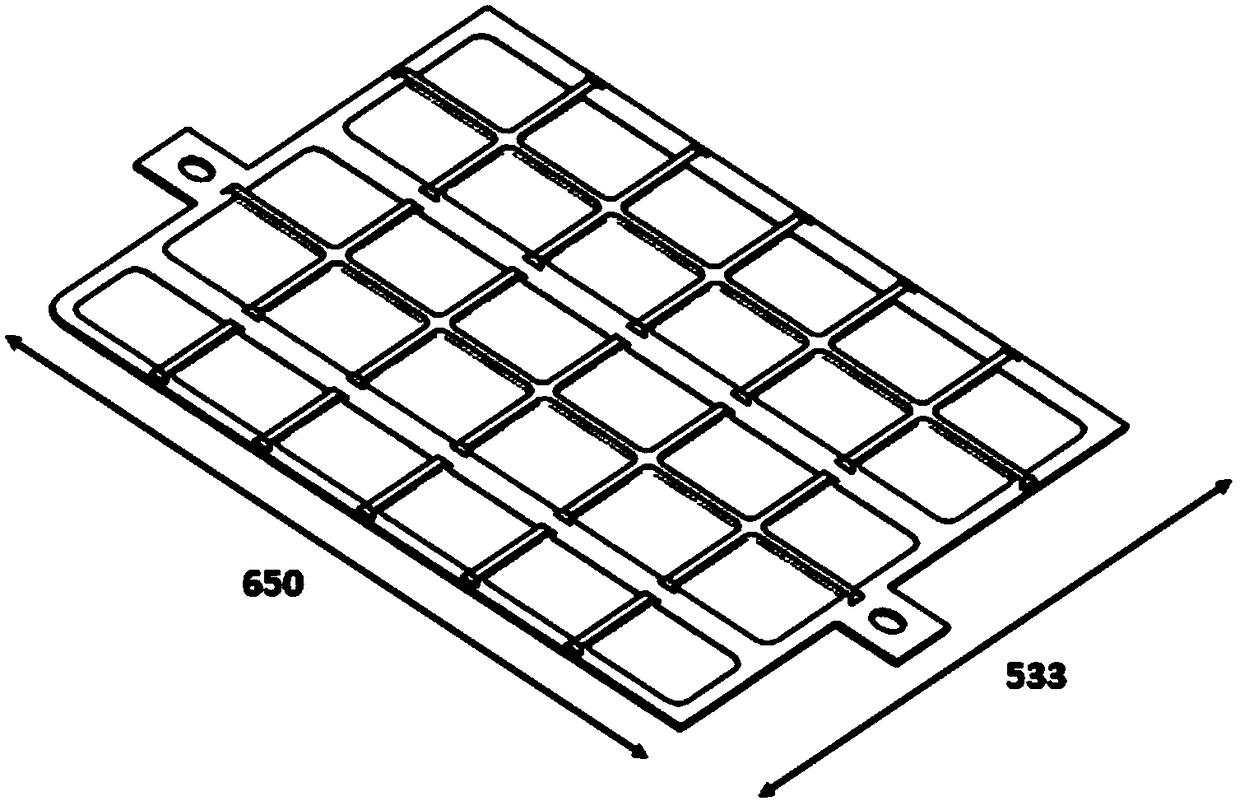

[0042] Taking an aluminum alloy variable-thickness special-shaped panel as an example, its shape and size are shown in figure 1 , the material of the part is 5A06 aluminum alloy, the length of the part along the bending line is 650mm, the bending angles are 130° and 140° respectively, the width of the slope is 110mm, the width of the horizontal plane is 216mm, the chamfer at the bend is R5, the curved surface The radian is R280mm. The thickest part is at the reinforcing rib, with a thickness of 8mm, the thinnest part is at the weight-reducing groove, with a thickness of 2.2mm, and the width of the reinforcing rib is 10mm.

[0043] The specific steps of the thermal creep plastic forming method for aluminum alloy variable-thickness special-shaped wall panels are as follows:

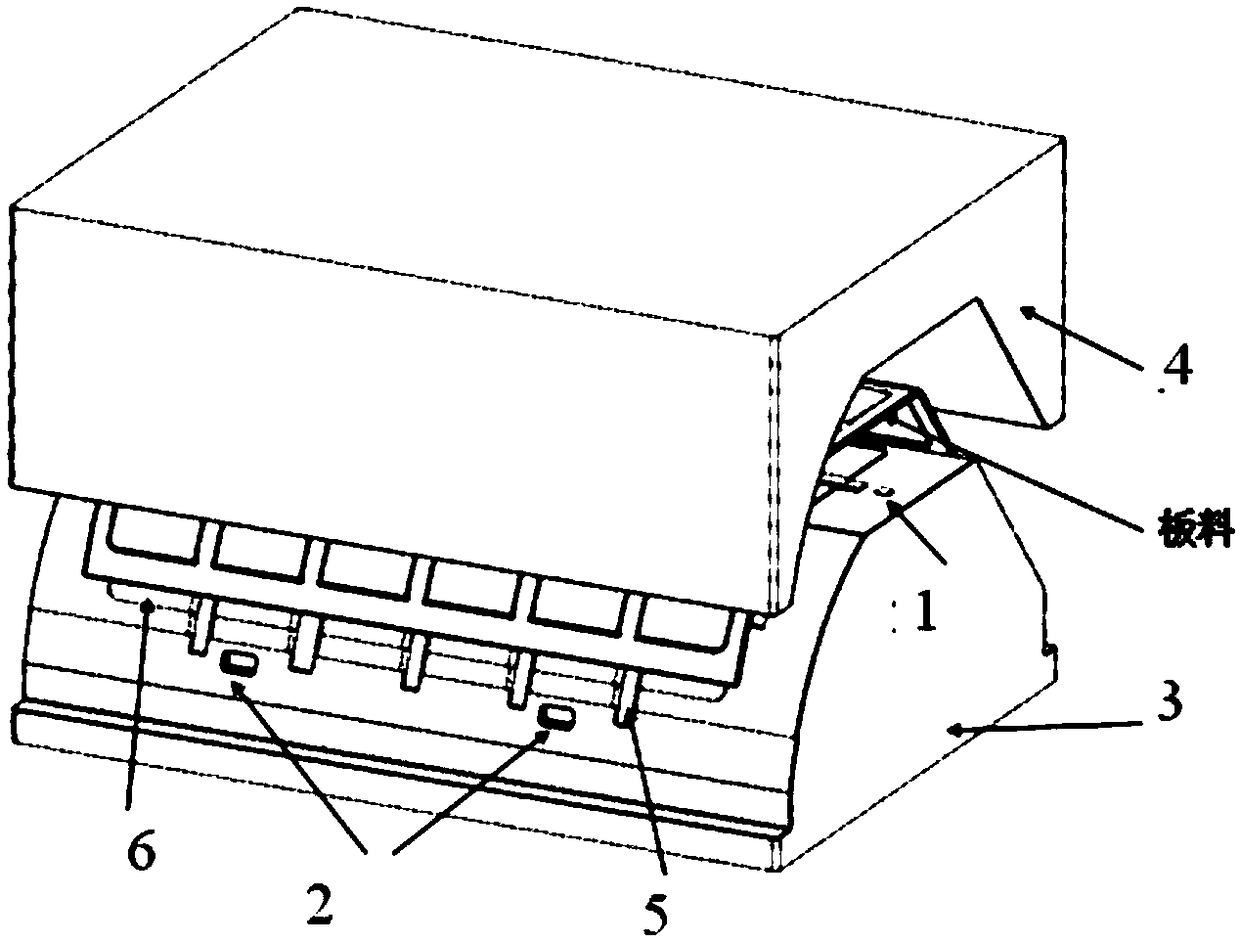

[0044] Step 1. Design thermal creep plastic forming mold: According to the external dimensions of the aluminum alloy variable-thickness special-shaped panel that needs to be formed, consider the linear exp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com