Preparation method of metallic/intermetallic compound laminar composite material

A technology of intermetallic compounds and layered composite materials, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of high material cost, low preparation efficiency, long reaction time, etc., and achieve high efficiency and process Ripening, reducing the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

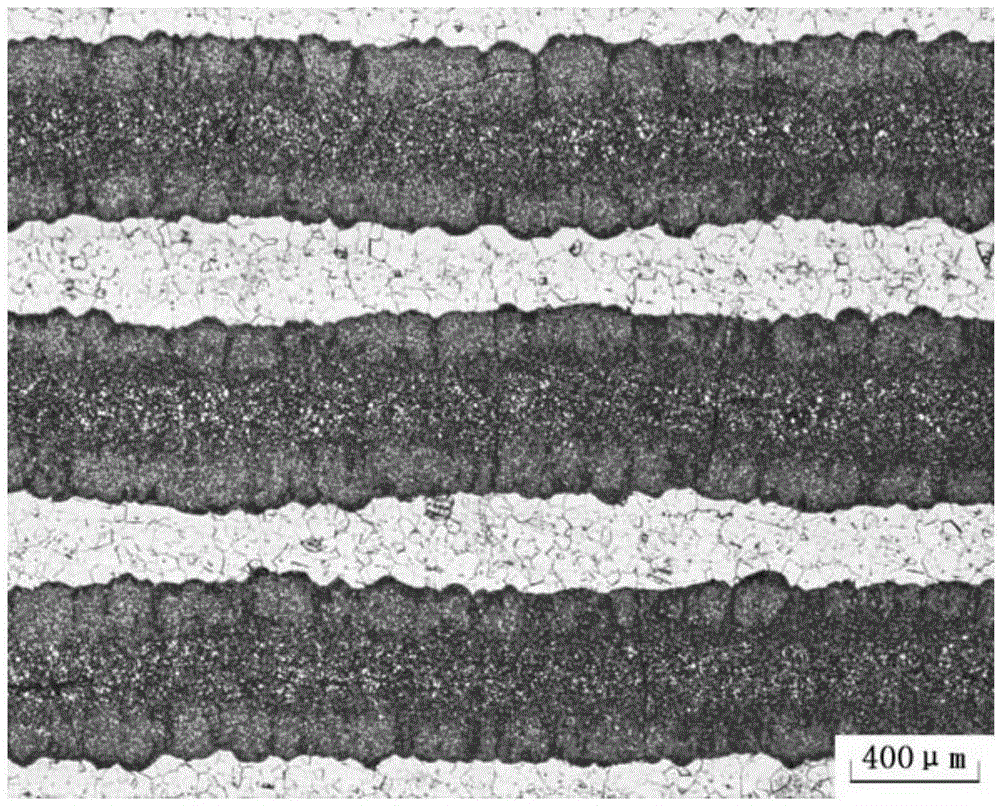

Image

Examples

Embodiment 1

[0031] This embodiment provides a method for preparing a metal / intermetallic compound layered composite material, the method comprising the following steps:

[0032] 1. Surface treatment: Use acetone to remove the grease on the surface of the plate, use a steel brush or abrasive belt to polish the surface of the plate, and activate the surface;

[0033] 2. Rolling composite: The 1mm-thick original plates are stacked together in the order of Ti-Al-Ti-Al-Ti-Al-Ti, and sealed in Q235 steel ladle by argon arc welding. Rolling is carried out at a rolling reduction of 50%.

[0034] 3. Annealing treatment: Anneal the rolled billet at 580°C for 0.5 hours to remove work hardening during rolling and improve the bonding quality of the internal interface of the clad plate.

[0035] 4. Sheath removal: use wire cutting to remove the sheath material, take out the composite board from the sheath, cut it from the middle, and repeat the above process (1)-(3) 2 times.

[0036] 5. In-situ react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com