Poly 1-butene/1-butylene-propylene copolymer in-reactor alloy and preparation method thereof

A technology of propylene copolymer and alloy in the kettle, applied in the field of polyolefin alloys, can solve the problems of long setting time, slow melt cooling rate, low strength, etc., achieve low shrinkage rate, improve crystal transformation rate, and excellent impact resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 3L full-sealed magnetic stirring stainless steel pressure polymerization kettle, pumped and replaced several times with high-purity nitrogen, then added 350g of 1-butene monomer, triethylaluminum (Al), and external electron donor diphenyl Dimethylsilane (Si) and supported Ti catalyst (Ti) 0.26g, where Al / Ti=150, Si / Ti=10 (molar ratio), add 60ml of hydrogen, evacuate the remaining 1-butane after polymerization at 28°C for 6h ethylene monomer, 77g of mixed gas of 1-butene and propylene was introduced, the reaction was continued for 2h, and the drying was terminated to obtain 330g of powdered poly-1-butene / 1-butene-propylene copolymer alloy in an autoclave.

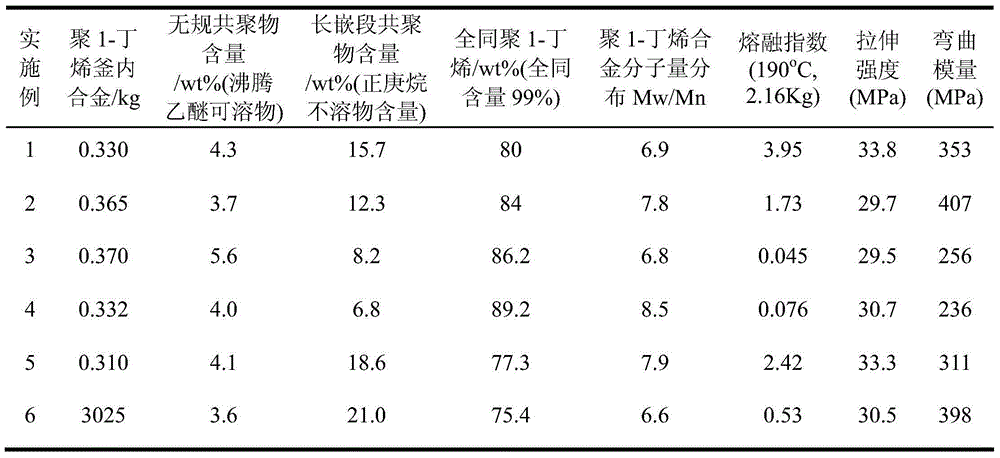

[0029] The properties of the alloy in the poly-1-butene kettle are shown in Table 1.

Embodiment 2

[0031] 3L full-sealed magnetic stirring stainless steel pressure polymerization kettle, pumped and replaced several times with high-purity nitrogen, then added 350g of 1-butene monomer, triethylaluminum (Al), and external electron donor diphenyl Dimethylsilane (Si) and supported Ti catalyst (Ti) 0.26g, where Al / Ti=150, Si / Ti=10 (molar ratio), add 40ml of hydrogen, after 6 hours of polymerization at 28°C, empty the remaining 1- For butene monomer, 100 g of mixed gas of 1-butene and propylene was introduced, the reaction was continued for 2 hours, and the drying was terminated to obtain 365 g of powdered poly-1-butene / 1-butene-propylene copolymer alloy in a kettle.

[0032] The properties of the alloy in the poly-1-butene kettle are shown in Table 1.

Embodiment 3

[0034] 3L full-sealed magnetic stirring stainless steel pressure polymerization kettle, pumped and replaced several times with high-purity nitrogen, then added 350g of 1-butene monomer, triethylaluminum (Al), and external electron donor diphenyl Dimethylsilane (Si) and supported Ti catalyst (Ti) 0.26g, where Al / Ti=150, Si / Ti=10 (molar ratio), after polymerization at 28°C for 6h, directly feed 76g of propylene, and continue the reaction for 2h , the drying was terminated to obtain 370 g of powdered poly-1-butene / 1-butene-propylene copolymer alloy in a kettle.

[0035] The properties of the alloy in the poly-1-butene kettle are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com