Coring equipment and coring process

A kind of equipment and inner core technology, which is applied in the field of coring equipment and coring technology, can solve the problems of low processing efficiency, material waste, low efficiency, etc., and achieve the effect of preventing dust from flying, improving the working environment, and preventing splashing everywhere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

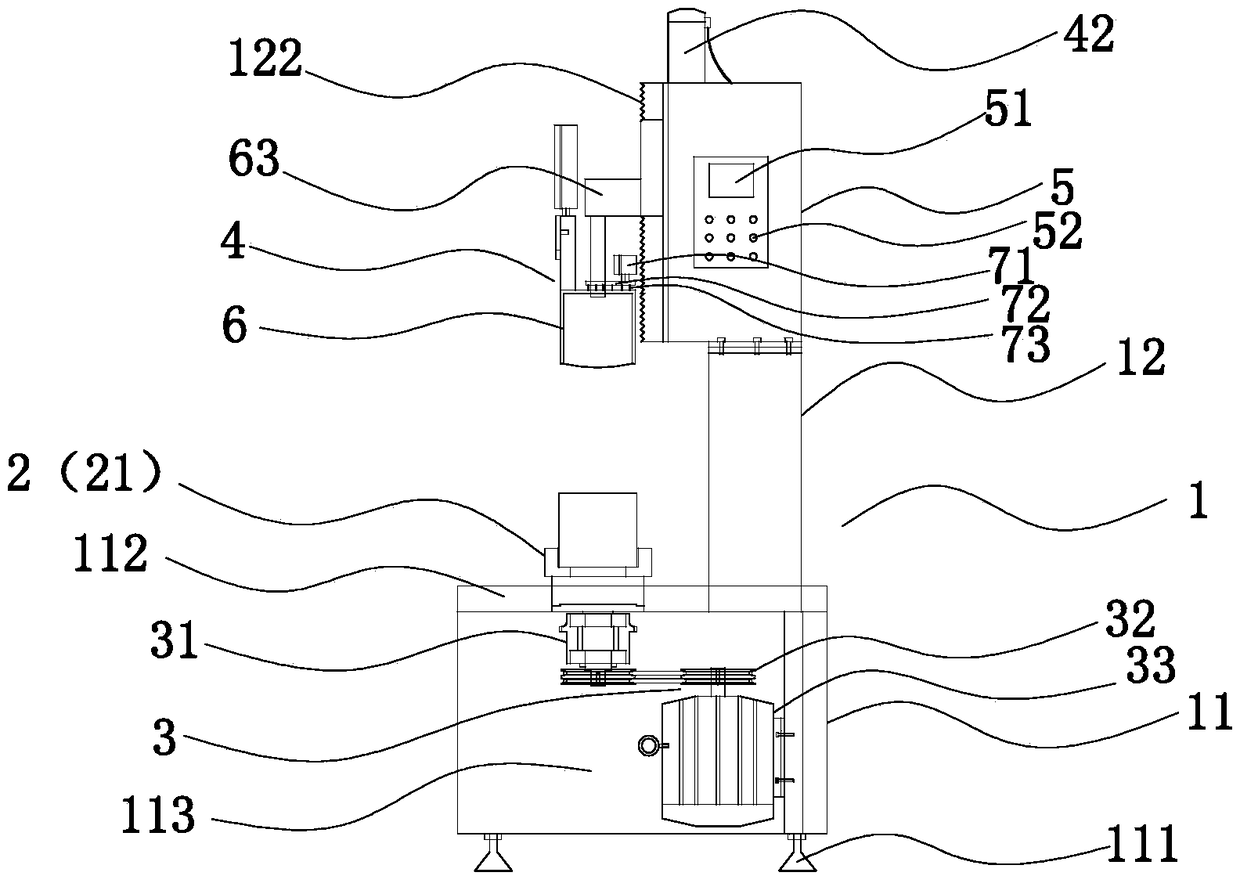

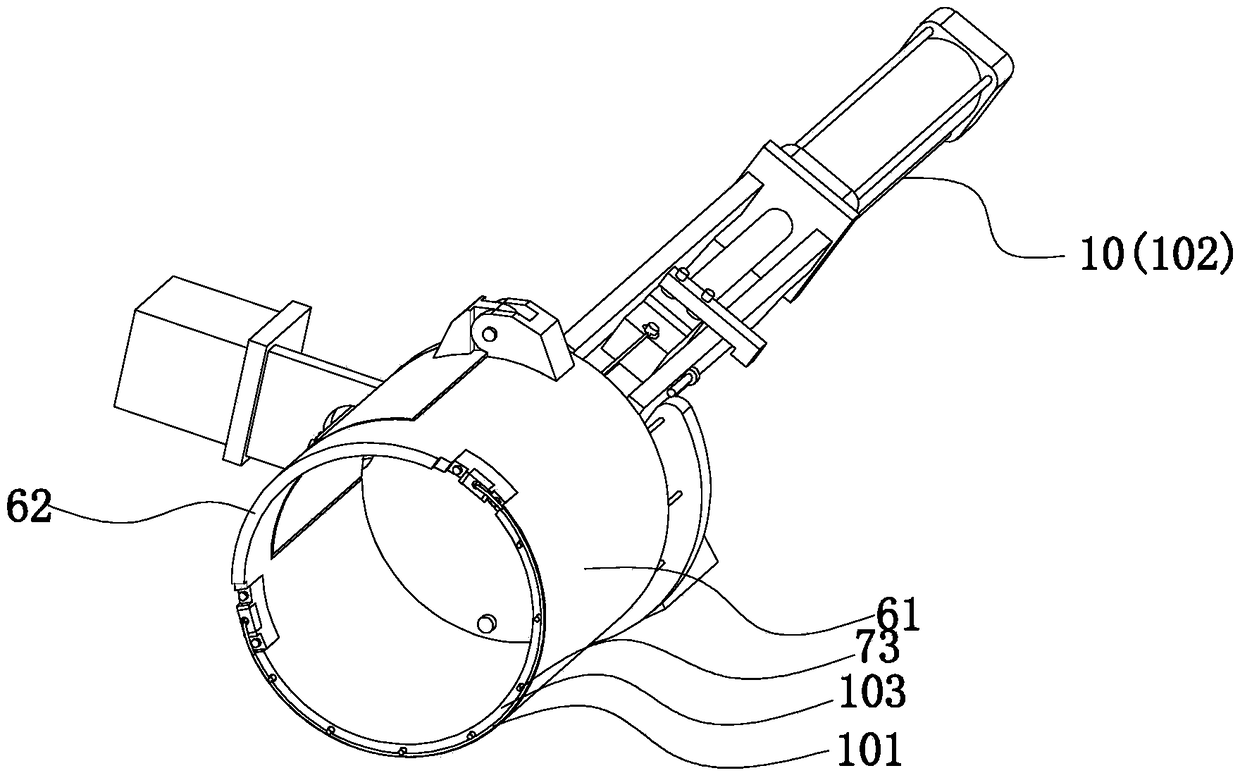

[0048] Refer to attached Figure 1-9 As shown, a coring device includes a main body 1, the main body 1 includes a base 11 and a support 12, the base 11 is connected and fixed to the support 12, the base 11 is a cuboid workbench, and the four corners of the base 11 are provided with The adjustment feet 111 are used for adjusting the overall height of the base 11 . The top surface of the base 11 is provided with a water blocking plate 112, and the water blocking plate 112 forms a concave cavity around the top surface to prevent water from flowing out from around the top surface of the base 11. Further, a water opening is provided in the concave cavity, and the water opening runs through the base 11 , so that water flows out from the top surface of the base 11 to the bottom surface of the base 11, and further, it can be introduced into the sewer pipe by connecting a water pipe.

[0049]The base 11 is provided with a clamping assembly 2 and a rotating assembly 3. The clamping ass...

Embodiment 2

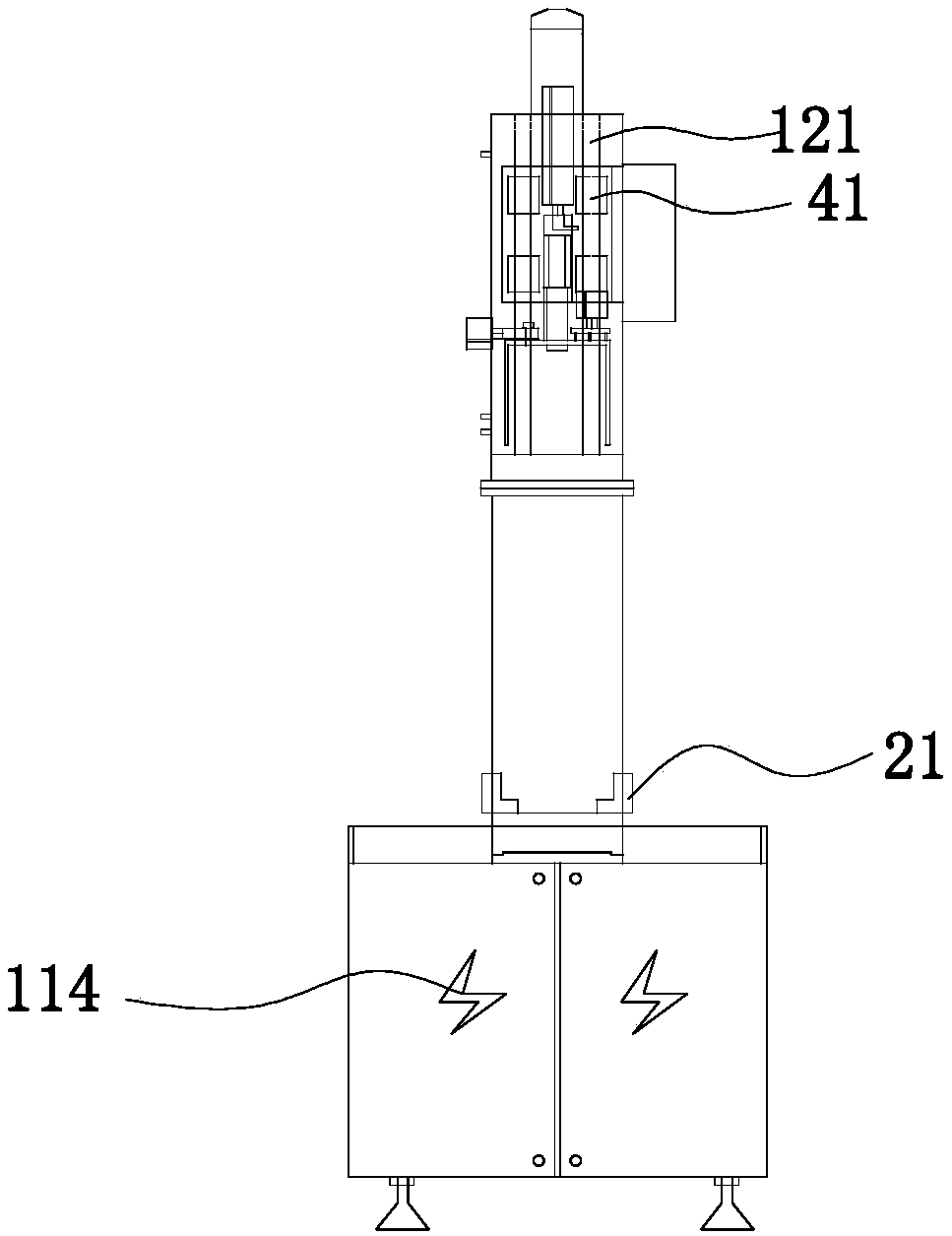

[0064] Refer to attached Figure 10 As shown, the difference between Embodiment 2 and Embodiment 1 is that the rotating assembly 3 is located on the coring assembly 4, that is, the clamping assembly 2 is fixed, and the rotating assembly 3 specifically drives the punching tool 61 Rotate, and its specific rotation is driven by the motor to drive the cutter pad 63 to rotate, driving the punching cutter 61 to rotate.

Embodiment 3

[0066] Refer to attached Figure 11 As shown, the difference between Embodiment 3 and Embodiment 1 is that it also includes a protective cover 81, the control mechanism is located on the protective cover 81, the protective cover 81 cooperates with the base 11 to form a sealed chamber, and the clamping assembly 2, Both the coring assembly 4 and the support 12 are located in the chamber. For the convenience of observation, the protective cover 81 adopts a transparent setting, and the protective cover 81 is provided with a window, which is convenient for placing and taking raw materials.

[0067] The setting of the closed chamber improves the working environment of the operator and prevents the dust from splashing everywhere. The operator only needs to open the protective cover 81 when picking up the material, and it is controlled by the control mechanism on the protective cover 81, that is, The process of coring can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com