Vibration type chain uniform oiling device

A vibrating and chain technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of wasting oil resources, oil waste, and affecting the working environment, so as to avoid oil dripping and waste, and the structure design is reasonable, Guarantee the effect of oiling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

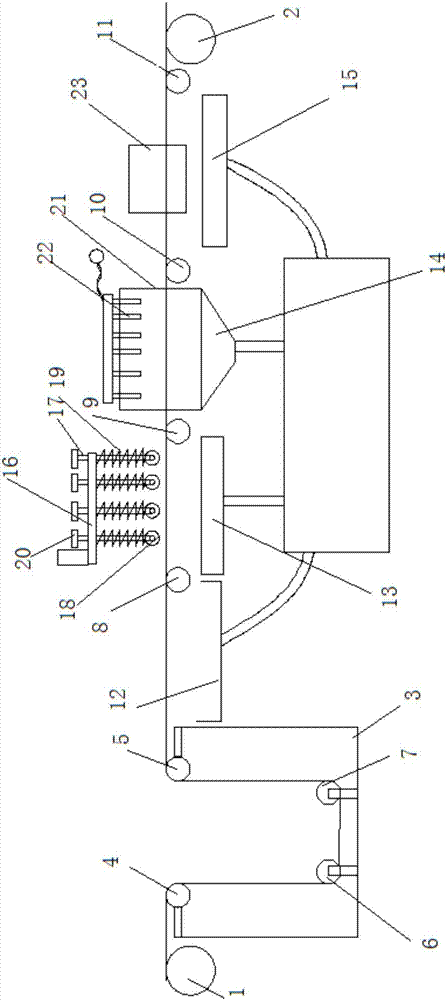

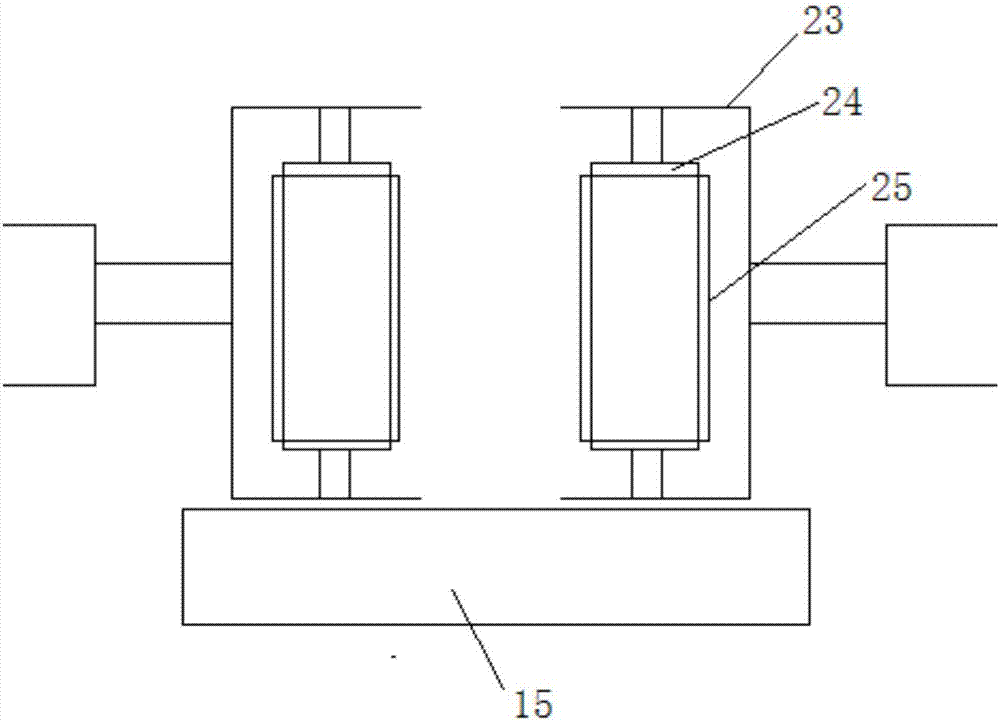

[0013] See attached picture.

[0014] A vibrating chain uniform oiling device, comprising two conveying sprockets 1 and 2 arranged at intervals, an oil storage tank 3 is arranged between the conveying sprockets 1 and 2, and an oil inlet is provided on the oil storage tank 3 , it is characterized in that: the upper port and the bottom end of the oil storage tank 3 are respectively equipped with sprockets 4, 5, 6, 7 through two corresponding brackets, and the sprockets 4, 5 of the upper port are connected with the conveying sprocket 1 and 2 are flush, and the outer side of the output end of the oil storage tank 3 is equipped with a first transition sprocket 8, a second transition sprocket 9, a third transition sprocket 10, and a fourth transition sprocket 11 for transmission with it. An oil receiving groove 12 is provided between the first transition sprocket 8 and the delivery sprocket on the oil storage tank 3, and a vibrating roller mechanism is erected between the first tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com